Daimler Rear-engine Layout

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

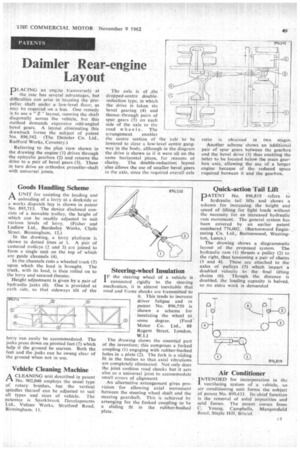

PLACING an engine transversely at the rear has several advantages, but difficulties can arise in locating the propeller shaft under a low-level floor, as may be required on a bus. One remedy is to use a Z" layout, running the shaft diagonally across the vehicle, but this method demands expensive odd-angled bevel gears. A layout eliminating this drawback forms the subject of patent No. 896,542. (The Daimler Co. Ltd., Radford Works, Coventry.)

Referring to the plan view shown in the drawing the engine (1) drives through the epicyclic gearbox (2) and returns the drive to a pair of bevel gears (3). These in turn drive an orthodox propeller-shaft with universal joints. The axle is of .the ' dropped-centre doublereduction type, in which the drive is taken Via bevel gearing (4) and thence through pairs of spur gears (5) on each side of the axle to the road wheels. The arrangement enables the centre section of the axle to be lowered to clear a low-level centre gangway in the body, although in the diagram the drive is shown as if it were all on the same horizontal plane, for reasons of clarity. The double-reduction layout also allows the use of smaller bevel gears in the axle, since thc required overall axle ratio is obtained in two stages.

Another scheme• shows an additional pair of spur gears between the gearbox and the bevel drive (3) thus enabling the latter to be located below the main gearbox axis, allowing the use of a longer engine because of the reduced space required between it and the gearbox.