The Truth About German By Transport and Economy The Editor

Page 28

Page 29

Page 30

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

The Concluding Instalment of Our Account of a Road Tour in the British Zone of Germany as Part of an M.O.W.T..Delegation

ARRIVING next day at Hanover, the delegation was met by Lieut.-Colonel J. M. Moran. Here we first inspected the Continental tyre factory and then that which is manufacturing A. F. accumulators. We were surprised to find both virtually undamaged and in production. The former produces about 600 tyres (of Buna synthetic rubber) daily, and is under the control of a Dunlop man, now a Major, who originally built and ran the Dunlop factory in Germany but escaped just before the war. The whole outpht is employed for British Army vehicles and essential German transport, this applying also to the batteries, the cases for which are made at the Continental works.

Some 1,500 German employees, men and women, many of the former being still in uniform, are at work on tyre making, but unless the rapidly diminishing supplies of coal can be augmented, this factory will have to close in a matter of days, and not only will more people be thrown upon the pittance paid by the German authorities, but German road transport may be brought to a halt in two or three months.

Next day a call was made at the main depot of the Hanover Tramway Company. Practically the whole centre of Hanover has been destroyed, but great efforts have been made to get the trams into operation. This rehabilitation of tramways applies to all parts of the British zone, for unless workers can be transported much of their time is taken in walking long distances, and with their meagre rations they are exhausted before they start work.

No encouragement is given by the C.C.G. to the development of bus services. Few routes are open in any German city, and these only as necessary links; no duplication of means for transport is permitted. A certain number of buses must be used by some factories for the transport of their workers, but liquid-fuel supplies are extremely limited, none being provided by us for use on German vehicles.

There is extremely little travel by train, for there are still some 1,300 damaged or destroyed railway bridges which have not been repaired or replaced. German civilians, including women and children, are, however, allowed to travel in empty goods wagons, and we saw hundreds in one train, packed into vans, with the doors left open for ventilation.

Hamburg, our next port of call, although badly damaged in many parts,, is not in such a serious condition as many other places. For one thing, it was not fought over, the local military commander capitulating to the Allies before this could occur.

We were accommodated at the famous Atlantic Hotel,

B2 k

which is now an officers' club. Visits were paid to the overhauling shops for subway and tramway vehicles, but these will not be of particular interest to our readers. We cannot refrain, however, from commenting upon the huge railway repair shops at Neumunster. These border the road for a considerable distance and present a picture of complete ruin of lasting memory. At Kiel we were introduced to Lieut.-Colonel Walker, M.C., and were taken for a sea trip around the harbour. Amongst the sights there were the battleship "Admiral Von Hipper," together with a partly sunken submarine, and the cruiser "Emden," all in a sorry state. The first of these had been partly camouflaged by painting windows, etc., on the superstructure in the endeavour to make it resemble houses.

Next we passed the battleship "Admiral von Scheer," with its keel and propellers in the air. Then we landed at what appeared to be a submarine pen, with a 16-ft. concrete roof, but which turned out to be a veritable assembly factory, where we counted 30 two-men submarines completed or nearing completion. There were even three sets of dynamometers for testing the engines, and the interior appeared to be nearly as large as the main hall at Olympia. Later we returned to Hamburg and made an inspection of some of the shops, which showed virtually empty shelves and display counters, the only articles available being a few ornaments.

The next morning was spent in a tour of the docks, blitzed areas, etc. It was noted with interest that three large submarine pens with enormously thick roofs had all' been penetrated by our special bombs. Incidentally, these pens have now been blown up.

We had an interesting chat with a " panzer " battalion commander who acts as liaison officer between our people and the mayor. We asked him whether he thought we were wise to take control or if It would have been better if we had left the Germans to "stew in their own juice," He was emphatically in favour of the former, as he was of the opinion that, without supervision, there would have been bloody revolution and complete' chaos.

In our tour of Hamburg otir eye was held by one of the air-raid shelters and flak towers, an enormous concrete building of 12 storeys, to hold 5,000 people and carry A.A. guns on the roof.

The following day was mainly devoted to conferences, ending in a farewell dinner at the officers' club at Bad Salzuflen, where the delegation had the Pleasure of turning the tables on its hosts.

Next afternoon we caught the duty train for Calais, a trip of 17 hours or so, ameliorated by a comfortable sleeper and a Mitropa dining car with a French staff. This train passed over the Rhine on what we understand is the longest temporary railway bridge that has ever been constructed, and which was built by the Royal Engineers. Crossing the Channel via Calais, we arrived in London shortly after 1.30 p.m. the following day.

Accompanying us on part of our journey both thr,ough Germany and on the way home was Mr. R. J. M. Inglis, ,C.I.E., T.D., chief of the Transport Division, and during most of the trip we had with us Brigadier M. M. Simpson, M.B.E., and his personal assistant, Sub. H. M. Howland, A.T.S., also Colonel J. B. Garrett, of the LOrry and Car Section; Colonel E. F. Horobin, who deals with buses and tramways; and Colonel S. L. Engel, who is concerned with highways and bridges. We were received by other high officers, to whom we referred last week.

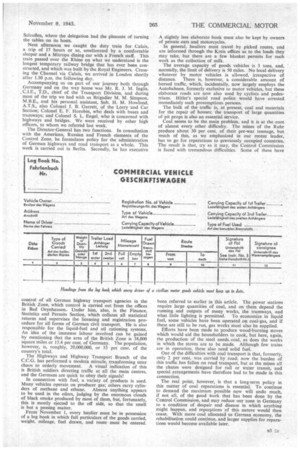

The Director-General has two functions. In consultation with the American, Russian and French elements of the Control Zone, he formulates policy for the administration of German highways and road transport as a whole. This work is carried out in Berlin. Secondly, he has executive control of all German highway transport agencies in the British Zone, which control is carried out from the offices in Bad Oeynhausen.. Under him, also, is the Finance, .Statistics and Permits Section, which collates all statistical returns and supervises the licensing and registration procedure for all forms of German civil transport. He is also responsible for the liquid-fuel and oil rationing systems. An idea of the immense labour involved can be gained by mentioning that the area of the British Zone is 38,000 square miles or 15.4 per cent. of Germany. The population, however, is, roughly, 20,000,000, or 33 per cent, of the country's total.

The Highways and Highway Transport Branch of the C.C.G. has performed a modern miracle, transforming utter chaos to orderly movement. A visual indication of this is British soldiers directing traffic at all the main centres, and the Germans are quick to obey their signals!

In connection with fuel, a variety of products is used. Many vehicles operate on producer gas; others carry cylinders of methane and ethane. Almost anything appears to be used in the oilers, judging by the enormous clouds of black smoke produced by most of them, but, fortunately, this is mostly ejected to the off side, so that the smell is but a passing matter.

From November 1, every haulier must be in possession of a log book in which full particulars of the goods carried, weight, mileage, fuel drawn, and route • must be entered. A slightly less elaborate book must also be kept by owners of private cars and motorcycles. In general, hauliers must travel by picked routes, and are informed through the Kreis offices as to the loads they may take, but there are a few blanket permits for such work as the collection of milk.

The average capacity of goods vehicles is 3 tons, and, norrMlly, the limit of delivery is 50 miles. No local delivery whatever by motor vehicles is allowed, irrespective of distance. There is, however, a considerable amount of horsed traffic, which, incidentally, now largely employs the Autobahnen, formerly exclusive to motor vehicles, but these elaborate roads are now also used by cyclists and pedestrians. Hitler's special road police would have arrested immediately such presumptions persons. The bulk of the traffic is, at present, coal and materials for the repair of houses; the transport of large quantities of pit props is also an essential service. Coal seems to be the main problem, and it is at the root of almost every other difficulty. The mines of the Ruhr produce about 30 per cent, of their pre-war tonnage, but much of this, as we emphasized in our recent leader, has to go for reparations to previously occupied countries. The result is that, try as it may, the Control Commission is faced with tremendous difficulties. Some of these have

been referred to earlier in this article. The power stations require large quantities of coal, and on them depend the running and outputs of many works, the tramways, and what little lighting is permitted. To economize in liquid fuel, some vehicles have been operated on coal-gas, and if these are still to be run, gas works must also be supplied.

Efforts have been made to 'produce wood-burning stoves which would aid the householders to cook, but here, again, the production of the steel needs. coal, as does the works in which the stoves are to be made. Although few trains are in operation, these also need solid fuel.

One of the difficulties with coal transport is that, formerly, only 2 per cent. was carried by road; now the burden of this traffic has fallen on road transport, but at the mines all the chutes were designed for rail or water transit, and special arrangements have therefore had to be made in this connection.

The real point, however, is that a long-term policy in this matter of coal reparations is essential. To continue to demand the maximum possible now will undo much, if not all, of the good Work that has been done by the Control Commission, and may reduce our zone in Germany to a condition of despair and disease in which anything might happen, and reparations of this nature would then cease. With more coal allocated to German economy, the rehabilitation could continue, and larger supplies for reparations would become available later.

IN 1939, this journal described a remarkable vehicle of light-alloy construction built by Jensen Motors, Ltd., of West Bromwich. About that time, four of these vehicles were completed; they differed in various respects but all embodied the same principles. Throughout the war they have been in constant use and have covered many thousands of miles apiece, without suffering any troubles due to the materials used or the methods of construction.

One was involved in a serious accident, being hit broadside on with such force that it was turned on its side, and its load was thrown over a hedge. This caused damage which with many conventional designs would, probably, have necessitated a new chassis frame, amongst other things. in this case, however, the side members were straightened and the diagonals re-riveted, since which repair the vehicle has been in regular use with entire satisfaction.

Apart from such a special case as that, it is instructive to learn that every rivet in those four vehicles has held tight, and there has been no sign of corrosion.

Using the experience gained with the early models, together with the lessons learnt in war-time fabrication of a variety of products, this same company has now designed and built the INSN lightweight commercial vehicle which combines the same basic light-alloy construction with carefully selected mechanical components by specialist manufacturers.

High-grade Proprietary Units

There is, for instance, a Perkins P6 oil engine, Borg and Beck clutch and Moss five-speed gearbox, with provision for power take-off. The three-piece propeller shaft has Layrub joints at the front, and Hardy-Spicer needle-roller mechanical joints elsewhere. A spiral-bevel fully floating rear axle completes the transmission system. Girling two-leading-shoe brakes in 16-in, drums are operated by Lockheed hydraulic controls. Tyres are 34 by 7 R.H.S. Dunlops (twins at the rear, of course) and steering is by Cam Gears, Ltd.

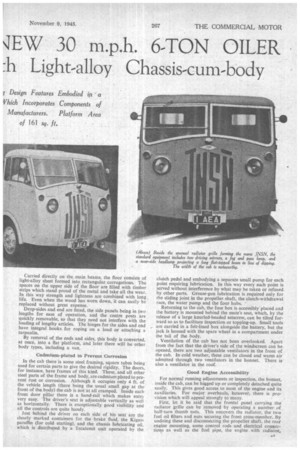

The Perkins P6 engine, it may. be recalled, has six cylinders of 3k-in. bore and 5-in. stroke. It develOps 77 b.h.p. at 2,250 r.p.m., and has a maximum torque of 184 lb./ft. at 1,000 r.p.m. The vehicle is, therefore, well able to take advantage of its legal maximum speed of 30 m.p.h., due to an unladen weight of less than 3 tons, although it can carry loads up to 6 tons.

While on the subject of carrying capacity, it may be noted that the loading area of the body is no less than 161 sq. ft.; the length and width are 23 ft. and 7 ft. respectively. With little doubt, this must make it the largest platform on four wheels under the regulations in this country. The corresponding overall dimensions of the complete vehicle are 27 ft. 6 ins. and 7 ft. 6 ins.

The body and the chassis together form, in effect, a unit. Two straight and deep I-section light-alloy beams extend from end to end of the vehicle, being joined by cross-members of similar section placed at suitable points, which include the spring anchorages. Diagonal braces, also of light alloy, are disposed along the length of the frame to increase lateral rigidity and to prevent any " lozenging." All the joints in this-main structure are riveted.

• Carried directly on the main beams, the floor consists of light-alloy sheet formed into rectangular corrugations. The spaces on the upper side of the floor are filled with timber strips which stand proud of the metal and take all the wear. In this way strength and lightness are combined with long life. Even when the wood has worn down, it can easily be replaced without great expense.

Drop-sides and end are fitted, the side panels being in two lengths for ease of operation, and the centre posts are quickly removable, so that they need not interfere with the loading of lengthy articles. The hinges for the sides and end have integral hooks for roping on a load or attaching a tarpaulin.

By removal of the ends and sides, this body is converted, at once, into a flat platform, and later there will be other body types, including a van.

Cadmium-plated to Prevent Corrosion In the cab there is some steel framing, square tubes being used for certain parts to give the desired rigidity. The doors, for instance, have frames of this kind. These, and all other steel parts of the frame and body, are cadmium plated to prevent rust or corrosion. Although it occupies only 4 ft. of the vehicle length (there being the usual small gap at the front of the body) the cab is not at all cramped. Inside each front door pillar there is a hand-rail which makes entry very easy. The driver's seat is adjustable vertically as well as horizontally. There is exceptionally good visibility and all the controls are quite handy.

Just behind the driver on each side of his seat are the clearly marked containers for the • brake fluid, the Kigass paraffin (for cold starting), and the chassis lubricating oil, which is distributed by a Tecalemit unit operated by the clutch pedal and embodying a separate small pump for each point requiring lubrication. In this way every such point is served without interference by what may be taken or refused. by other parts. Grease-gun lubrication is required only for the sliding joint in the propeller shaft, the clutch-withdrawal race, the water pump and the four hubs. '

Returning to the cab, the fuse box is accessibly placed and the battery is mounted behind the mate's seat, which, by the release of a large knurled-headed setscrew, can be tilted forward so as to facilitate inspection or topping-up. Small tools ,. are carried in a felt-lined box alongside the battery, but the jack is housed with the spare wheel in a compartment under the tail of the body. • Ventilation of the cab has not been overlooked. Apart from the fact that the driver's side of the windscreen can be opened, there are two adjustable ventilators in the front of the cab. In cold weather, these can be closed and warm air admitted through two ventilators in the bonnet. There is also a ventilator in the roof.

Good Engine Accessibility For normal running adjustments or inspection, the bonnet, inside the cab, can be hinged up or completely detached quite easily. This gives good access to most of the engine and its auxiliaries. For major overhauls, hoWever, there is provision which will appeal strongly to many.

First, let it be said that the frontal panel carrying the radiator grille can be removed by operating a number of half-turn thumb nuts. This uncovers the radiator, the two fuel oil filters and nuts securing the front cross-member.. By undoing these and disconnecting the propeller shaft, the rear engine mounting, some control rods and electrical connections as well as the fuel pipe, the engine with radiator,

gearbox and the exhaust system can be wheeled out on a special jacking trolley as a unit. Four large dowels at the front guide the unit into place when it is being returned, and relieve the retaining studs of all sheer stress.

This scheme opens up the possibility of exchanging a worn engine for a new or reconditioned one in an hour or so, thus involving little loss of operating time and earning capacity.

Convenience has also been studied in small ways. For instance, there is a snap-fastening cap for the filter of the radiator, and for the 20-gallon fuel .tank which is mounted on the near .side. Then, too, the lighting equipment is calculated to ease the lot of the driver at night and of those who meet him. Of the two head lamps, the near-side one is fitted with a split reflector which gives a flat-topped beam. The dipping switch, in fact, extinguishes only the off-side head lamp, leaving a strong low beam which most drivers will agree is a good deal more useful than the usual dipped beam. Two side lamps also are built into the front of the vehicle. The interior of these and of the head lamps are accessible from inside /he cab.

Mounted at the height specified by the maker, 15 ins. above road level, is a pass light or fog lamp, which has its own separate switch in the cab. A stop light and two rear lamps are placed (with the registration number) in a recess at the back of the chassis, so that they are protected from impact with loading bays and the like. Such details as this show that the sponsor of this new JNSN has made a serious effort to solve the little problems which add up to so much in road transport. Commendable as this is, it pales into insignificance beside the main achievement. It is no small thing to evolve a really sturdy vehicle which can carry a 6-ton load and yet be legally entitled to its 30 m.p.h., but it is amazing that such a weight of mosi average commodities can be stowed direct on its huge floor For many trades and industries the JNSN seems likely 1, set a new standard in transport.