THE LARGE PNEUMATIC TYRE.

Page 119

Page 120

If you've noticed an error in this article please click here to report it so we can fix it.

Its Influence Upon the Use and Design of Commercial Vehicles.

FOR some years the wider use of pneumatic tyres has been keenly advocated and fostered by The Commercial Motor, and we have published many -articles dealing with the peculiar advantages of tyres of this type, culminating in one written by Mr. Shrapnell-Smith, which appeared some eleven months ago, anti which dealt very succinctly with pneumatic-tyre characteristics. Mr. Shrapnell-Smith then said the solid rubber tyre is as much a phase in commercial motoring as was the steel tyre," and that this remark was fully justified is adequately proved by the ever widening use which is being made of pneumatic tyres.

When it is considered that the first cost of a set of pneumatics is considerably greater than that of a set of solids, whilst to change a fleet from the latter to the former type usually necessitates changing all the wheels, It is clear that as so many fleet owners have made this change, there must be some very definite advantages to be gained. Probably the most important is that the pneumatic tyre, in virtue of the increase of riding comfort which produces, permits of a considerably greater mileage being covered per day.

Improved riding comfort, of course, not only reduces the fatigue of the driver, but also enables a higher average speed to be maintained over rough roads. Furthermore, as regards passenger-carrying vehicles, the riding public has shown a distinct preference for those fitted with pneumatics. In some eases the increase in daily • mileage permitted by changing from solids to pneumatics. has amounted to as much as 40 per cent., and this, of course, means a considerable re

duction in the cost of running the vehicle, worked out per mile.

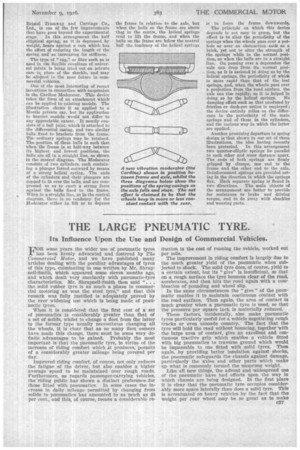

The Improvement in riding comfort Is largely due to the much greater yield of the pneumatic when subjected to shock. The solid tyre does, of course, yield to a certain extent, but its "give" is insufficient, so that on a rough surface the tyre bounces clear of the road, accelerates, and then hits the road again with a combination of pounding and wheel slip.

In the same circumstances the "give" of the pneumatic enables it to maintain continuous contact with the road surface. Then again, the area of contact is much greater when a pneumatic tyre is used, so that the pressure per square inch is materially reduced.

These factors, incidentally, also make pneumatic tyres particularly useful for a vehicle negotiating rough tracks or even unmade country. The fact that the tyre will hold the road without bouncing, together with the large area of contact, give an excellent and continuous tractive grip which enables a vehicle fitted with big pneumatics to traverse ground which would be impassable to one fitted with solid tyres. Then again, by providing better insulation against shocks, the pneumatic safeguards the chassis against damage, particularly the axles and other parts which make up what is commonly termed the unsprung weight.

Like all new things, the advent and widespread use of the pneumatic have had effects upon the way in which chassis are being designed. In the first place it is clear that the pneumatic tyre occupies considerably more space laterally than does a solid tyre. This is accentuated on heavy vehicles by the fact that the weight per rear wheel may be so great as to make the use of a single pneumatic inadvisable, so that twin tyres are needed.

This is a somewhat serious matter, as will be gathered when it is realized that four pneumatics of the common 8-in. section go to make a total width of nearly 3 ft. To accommodate these tyres it is either necessary to increase the width of the vehicle or decrease the space „available for the load. This is one of the chief reasons for the widespread use of the rigid six-wheeler in America, the .idea being to use two axles with four single pneumatics in place of one axle with twin pneumatics at each end.

The six-wheeler has, of course, other particular advantages, but it is nevertheless a fact that its rapid progress is very largely due to the fact that the chassis designer found it necessary to revise his ideas if he was to use pneumatic tyres successfully for carrying heavy loads.

Another point is the arrangement of the brake gear when pneumatic tyres are fitted. Tn order to keep a low platform level the overall size of the wheel must not be very great, and as the section of the tyre is large this means that the rim diameter is unusually small. Concurrently, brakes have been receiving greater attention, largely in the direction of iinproving their efficiency by increasing the diameter of the drums. A point. has now been reached when it is difficult to accommodate the drum and the wheel without bringing the periphery of the former very close to the rim of the latter.

As a result, it is not surprising to find that trouble has been caused by the flow of heat from the brake drum to the wheel in districts abounding in long and heavy gradients, this flow resulting in raising the temperature Of the rim to a point sufficiently high to affect the covers of the tyres very adversely.

The effect of these phenomena has already been seen,. many manufacturers making special provision for the conductance of the heat away from the wheel rims, whilst others have provided blades acting as fans to ensure a flow of air between the rim and brake drum. /t is considered by many people that so serious is this problem likely to become that it may result in a much extended use of transinission brakes.

In this connection it /mist also he realized that the section of pneumatic tyre employed is likely to grow larger rather than smaller. This is due to the fact that the lower the air pressure the better is the riding comfort, other; things being equal.'

Thus, if the present-day pressure range of 75 lb. to 125 lb. per square inch is to be reduced all round until it becomes 50 lb. to 100 lb. per square inch, there will be quite a marked all-round increase of tyre sections', which will accentuate the difficulties with rim's and brake drums.