How to Keep Your Lorry Fit. XI.

Page 4

Page 5

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

The Belsize 3.-ton Commercial Chassis Forms the Subject of our Eleventh Article.

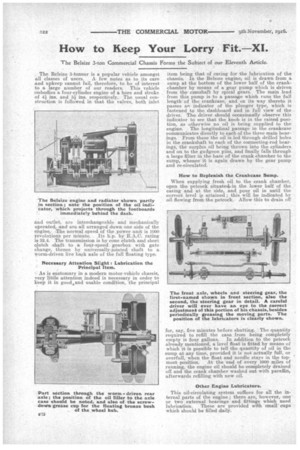

The Belsize 3-tonner is a popular vehicle amongst all classes of users. A few notes as to its care and upkeep cannot fail, therefore, to be of interest to a large number of our readers. This vehicle embodies a four-cylinder engine of a bore and stroke of 41 ins. and 51 ins. respectively.. The usual construction is followed in that the valves, both inlet and outlet, are interchangeable and mechanically operated, and are all arranged down one side of the engine,. The normal speed of the power unit is WOO revolutions per minute. Its h.p. by R.A.C. rating is 32.4. The transmission is by cone clutch and short clutch shaft to a four-speed -gearbox with gate Change, thence by universally-jointed shaft to a worm-driven live back axle of the full floating type.

Necessary Attention Slight : Lubrication the Principal Item.

As is customary in a modern motor-vehicle chassis, very little attention indeed is necessary in order to keep it in good,.and usable condition, the principal item being that of caring for the lubrication of the chassis. In the Belsize engine, oil is drawn from a sump at the bottom of the lower half of the crankchamber by means of a gear pump which is driven from the ca:mshaft by spiral gears. The main lead from this pump is to a passage which runs the full length of tho crankcase, and on its way thereto it passes an indicator of the plunger type, which is fastened to the dashboard and in full view of the driver: The driver should occasionally observe this indicator to see that the knob is in the raised position, as otherwise no oil is being supplied to the. engine. The longitudinal passage in the crankcase communicates directly to each of the three main bearings. From these the oil is led through drilled holes in the crankshaft to each of the connecting-rod bearings, the surplus oil being thrown into the cylinders and, on to the gudgeon pins' and finally falls through a large filter in the bate of the crank chamber to the sump, whence it is again drawn by the gear pump and re-circulated.

How to Replenish the Crankcase Sump.

When supplying fresh oil to the crank chamber, open the petcock situated, in the lower half of the casing and at the side, and pour, oil in until the correct level is attained ; this will be indicated by oil flowing froin.the petcock. Allow this to drain off

for, say, five minutes before shutting. The quantity required to refill the case from being completely empty is four gallons. In addition to the petcock already mentioned, a level float is fitted by means of which it is possible to tell the quantity of oil in the sump at any time, provided it is not actually full, or overfull, when the float and needle stays in the topmast position. At the end of every 1000 miles of running. the engine oil should be completely drained off and the crank chamber washed out with paraffin, afterwards refilling with new oil.

Other Engine Lubricators.

This oil-circulating system suffices for all the internal parts of the engine ; there are, however, one' or two external bearings and fittings which need lubrication. These are provided with small cups which should be filled daily.

Gearbox Lubrication Simple.

The gearbox lubrication is simple in the extreme. All that the driver has to do in the case of this unit is to refill every 1000 miles with thick gear grease after having removed the used lubricant. It is advisable on each of these occasions carefully to clean out the box and to make quite sure, that no chips of steel or other foreign material are floating about in the box. They may get into the ball bearings and cause serious damage.

The Rear-axle Case and Differential Gear.

The rear-axle case requires a little more attention. The lubricators which are found on the hubs of the road wheels, should frequently be screwed down. The axle case itself must be filled to the correct level every 250 miles, or before commencing any long journey, with thick oil. The front axle also is provided with lubricating cups which should be screwed down as required. All these cups should be kept supplied with thick grease.

The Steering Gear. The Universal Joints.

The steering box should be kept well filled with grease, and the joints on the steering connections

kept well lubricated. The universal joints on the

Bolsize being of flexible material, usually leather, do not need any attention in respect of lubrication.

Do Not Forget the Small Lubricators.

As usual in almost every commercial-vehicle chassis, we find it advisable to draw the driver's attention to the need for screwing down the lubricators on the cross-member bracket behind the clutch, and for paying attention to the various grease cups and oil cups about the brake and control gear generally.

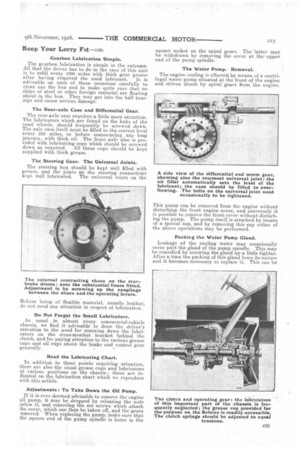

Read the Lubricating Chart.

In addition .to these points requiring attention, there are also the usual grease cups and lubricators at various positions on the chassis ; these are indicated on the lubrication chart which we reproduce with this article.

Adjustments To Take Down the Oil Pump.

If it is ever deemed advisable to remove the engine oil pump, it may be dropped by releasing the nuts below it, and removing the set screws which attach the cover, which can then be taken off, and the gears

• emoved. When replacing the pump, make sure that the square end of the pump spindle is home in the

square socket on the spiral gears. The latter may be withdrawn by removing the cover at the upper end of the pump spindle.

The Water Pump. Removal.

The engine cooling is effected by means of a centrifugal water pump situated at the front of the engine and driven direct by spiral gears from the engine.

This pump can be removed from the engine without disturbing the front engine cover, and conversely it is possible to remove the front cover without disturbing the pump. The pump itself is attached by means of a special cap, and by removing this cap either of the above operations may be performed.

Packing the Water Pump Gland.

Leakage • of the cooling water may occasionally occur past the gland of the pump spindle. This may be remedied by screwing the gland up a little tighter. After a time the packing of this gland loses its nature and it becomes necessary to replace it. This can be

effected by first of all removing the small set screw and the gland-nut lock, slide the lock away, then remove the nut, when the gland may be packed and re-assembled by reversing the operations noted above.

Remove All Water on Frosty Nights.

When putting the chassis away on nights which are likely to be frosty, all the water should be removed from the cylinder jackets and circulating system. This may be effected by opening the drain cock below .„ the radiator. To lessen the risk of freezing resort is ocasionally had to the addition of glycerine or alcohol to the cooling water. While this procedure is satisfactory -up to a, certain point, it has the disadvantage of being somewhat expensive, and, if 'alcohol be used, there is in addition a fairly rapid evaporation of the liquid, commercial-vehicle engines running generally at fairly high temperature.

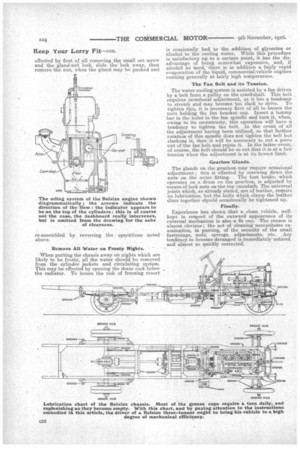

The Fan Belt and its Tension.

The water cooling system is assisted by a fan driven by a belt from a pulley on the crankshaft. This belt requires occasional adjustment, as it has a tendency to stretch and may become too slack to drive. To tighten this, it is necessary first of all to loosen the nuts holding the fan bracket cap. Insert a tommy bar in the holes in the fan spindle and turn it, when, owing to its eccentricity, this operation will have a tendency to tighten the belt. In the event of all the adjustment having been utilized, so that further rotation of this spindle does not tighten the belt but slackens it, then it will be necessary to cut a piece out of the fan belt and rejoin it. In the latter event, of course, the belt should be so cut that it is at a fair tension when the adjustment is at its lowest limit.

Gearbox Glands.

The glands on the gearbox may require occasional adjustment ; this is effected by screwing down the nuts on the outer, fitting. The foot brake, which operates on a drum on the gearbox, is adjusted by means of leek nuts on the top camshaft. The universal joints which, as already stated, are of leather, require no lubrication, but the bolts which clamp the leather discs together should occasionally be tightened up.

Finally.

Experience has shown that a clean vehicle, wellkept in respect of the outward appearance of its external mechanism is also a fit one. The reason is almost obvious ; the act of cleaning necessitates examination, in pas-sing, of the security of the small fastenings, nuts; springs, adjustments, etc. Any tendency to become deranged is immediately noticed, and almost as quickly corrected.