HANDLING AIDS for Transit Depots

Page 64

Page 65

Page 66

Page 67

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

By

P. A. C. Brockington, A.M.I.Mech. E.

Factors to be Considered in Buying Equipment : "Look to Your Maximum Load" is the Motto

ONE of the most important industrial trends since the war has been the increasing demand for a transport system that can virtually eliminate delays in the collection of finished goods from traders' premises, and this in part accounts for the growth of C-licensed fleets.

In many cases a prerequisite to the traffic being given to a haulier is that he should possess a transit depot or warehouse to which goods can be immediately transferred by a collection vehicle for later transhipment to a trunking lorry. The initial cost of establishing such a depot is often a serious economic factor, but up-to-date transit-warehouse facilities often enable regular traffic to be obtained at a good rate and the trunking vehicles to be operated far more efficiently.

Justification for establishing a depot of this type will frequently depend on the diversity of the goods, with regard to shape, weight per unit load, ability to support an imposed load and many other characteristics, as well as the total tonnage to be inoved. Details of the handling methods employed will also depend on whether the depot is based on existing premises, or is a new building having a layout arranged in accordance with the haulier's requirements, with limitations in most cases as to cost and space.

Bogy of Cost

To many operators, the advantages offered by a driver-controlled fork-lift truck cannot compensate for its high first cost. It is easy to overlook the benefits that can be derived from employing comparatively low-cost equipment, which in some cases could be used in conjunction with a fork truck, if a greater volume of traffic eventually, justified its purchase. This review will, therefore, concentrate on the simpler types of mechanical-handling aid.

An obvious preliminary to building a transit depot, or the conversion of existing premises, is to make an accurate estimate of all space requirements and the extent to which the proposed facilities match these requirements. It is normally

essential to make the optimum use of a limited space rather than provide. another depot elsewhere. Whether or not' there will be sufficient space for the traffic already carried (and the total volume that may be expected in the foreseeable future) may well depend on the type of handling equipment employed. It may be necessary to make use of decks at different levels and to save space by stacking to the maximum height.

The last comment. suggests a factor which may tip the balanc6 in favour of acquiring a larger driver-controlled fork-_. lift truck, which can stack heavily loaded. pallets to the necessary height. :To exploit the potential advantages of easy stacking to the full may be impossible, however, unless a reasonable proportion of the goods is of uniform weight and shape. and is stable when pallet loaded.

For mixed loads, which may. include fragile components and small, irregularshaped parts, a heavier, enclosed stillage with corner posts is needed to give direct support to the imposed load; alternatively a simpler type of post pallet may be employed if it is necessary to enclosd the load.

Unless a relatively small proportion of the goods is stacked, the. space required for gangways is of first consideration, and.. this may be a function of the rnanreuvrability of the machines or the dimensions

of the static handling equipment: •

A vexed problem to many .operators who normally carry smaller consignments is the necessity to handle for important customers occasional loads of far, greater weight than the average.. The crow-barand-roller method or equivalent can generally be employed given sufficient man-power; but if there are differences in deck level adequate ramps inust be available. The provision of more up-todate handling methods, although immediately uneconomic, may well help to create additional traffic of this type. The decision of .the operator on such a problem could set a standard of handling for all the goods moved. " Look to your maximum load" may be very opportune advice, more especially if there is a possibility that the occasional load will become a

regular load. .

-Apart from the occasional load, the maximum weight of regular loads is a factor of the greatest importance when handling equipment is being considered. "ft is essential that there should be a reasonable excess-weight safety margin, and this applies to pallets and stillages, gravity conveyors, handand power operated . trucks, conveyor-loaders, stackers, chutes, hoists and practically every other type of handling equipment. The more complex the handling arrangements, the greater will be the time wasted in the event of a breakdown.

. • Specialized Loads Operators who cater for specialized loads, such as .sacks, drums and crates of a.certain size, are fortunate in being able to assess their requirements much more exactly than the haulier or C-licensee carrying mixed loads. They are at least assured of the ready co-operation of Abe equipment manufacturers producing equally 'specialized handling and storage equipment. Mixed loads, however, demand greater ingenuity on the part of the 'operator, and, in the main, inuIti-purpose rather than specialized equipment will, therefore, he considered.

The ideal ofavoiding the transfer of goods from one level to another at both ends of a run can be achieved only if both loading decks approximate to the vehicle floor height. •At best it is inevitable that there will often be more than a slight difference between the levels. Makeshift ramps are often the cause of loading troubles, and it is pertinent that H. C. Slingshy, Ltd., 89 Kingsway, London, W.C.2, have produced a range of lightalloy dockboards and ramps which can be easily handled by one man to give positive location. They can also be carried on the vehicle with the minimum loss of payload.

A flat-type dockboard with safety stops and side guard rails is available in two

sizes, the larger of which has a length of 72 in., weighs 75 lb. and has a load capacity of 10 cwt. Also having a capacity of 10 cwt., a taper-ended flush-type dockboard is designed to bridge a gap between the vehicle and the deck; it is equipped with a deck-contact safety bar and angled stop brackets, to anchor the inner end to the floor. The larger of two boards in this category -has a length of 72 in. and weighs 69 lb. The light

alloy ramps include a number of types, the lightest of which is a 14-ft. perforated ramp having a capacity of 500 lb. and weighing 130 lb. All the ramps can be fitted with wheels to facilitate handling.

Of Swiss design, the Vilver electromechanical lifting platforms, now manufactured in this country by C. H. Johnson (Machinery), Ltd., Athwood, Stockport, Cheshire. enable the load to be wheeled onto the platform at one level and transferred to the 'vehicle floor at another. This equipment is being extensively used on the Continent.

The smallest of the standard models has a capacity of 5 tons and can operate at the high lifting speed of 40 ft. per min.; the 5-ft. by 3-ft platform is raised by wire 'ropes at the four corners controlled by a compensating mechanism. Another 5-ton platform measures 9 ft. 10 in. by 6 ft. 7 in. and is operated by screwed rods in the .columns, There is also a 15-ton platform with a 26-ft. 3-in. by 7-ft. 7-in. platform which is raised by the same means, at a speed of 10 ft. per min. A notable feature of all the platforms is the very limited excavation required; the depth for the smallest type is only 4 in. The total lifting height is decided by the needs of the user Self-adjuAing Table Yet to be fully exploited for vehicle loading the Autolevel -table evolved by Barron and Shepherd, Ltd., 16 Blackfriars Lane, London, E.C.4, operates on a novel but simple principle which should appeal to many road transport users. The platform of the table is controlled by a spring-compensated mechanism which automatically adjusts the height of the platform to the weight of the load. As each package is removed the platform moves upwards a corresponding amount, and the loader on the vehicle would handle packages at the same . level throughout the operation. The table can be handled with the aid of a truck, or it can be fitted with wheels for direct manhandling.

The operator who is considering the type of stacker-loader or conveyor-loader best suited to his needs can select equipment from a very wide range of machines. In many cases his choice will depend on the maximum-load factor.

c/8 The range of Slingsby mobile stackers include handand electrically operated machines with load-lift capacities up to 15 cwt. to a height of 12 ft. These are particularly suitable for vehicle loading as well as stacking in the depot. The concern also manufacture a variety of pallet and platform trucks.

Practically all the makers of stackerloaders produce machines that, by virtue of their low weight, could be carried on a vehicle for use at the destination for unloading or internal movements. In the opinion of many manufacturers this could be a very valuable adjunct to operational efficiency.

Powered by a mains-operated electric motor or small petrol engine, the straddletype auto-loaders and stackers produced by Lodematic, Ltd., Clitheroe, Lanes, have . been specifically designed or

operators who require an easY means for vehicle loading and stacking, but to whom capital outlay for a driver-controlled . fork-lift truck would not be warranted. The largest model is capable of lifting 21 cwt. to a .height of 12 ft., and all the machines are fully automatic in that the platform stops at any predetermined level, returning when the load is removed. If reqUired, a device can, be fitted which records the number of liftS. . In its standard form the t5-20-cwt. stacker; which is included in the range of mechaniCat-handling equipment produced by Eccles (Birmingham), Ltd.,. Arrow Road, Redditc'n, is'. hand-operated by means of a hydraulic pump, but may be equippedwith a . mains-operated or battery-electric system. If a battery is

employed, a wall-mounted charger is supplied which can he used to charge spare batteries when the machine is used for shift work. In addition to an Eccles range of 10-cwt. to 2-ton pallet trucks, there is also a " long-load truck for moving pipes, beams and so on. An interesting Eccles stillage is one designed lo provide access to the platform when I second stillage is stacked above it.

Versatility is an important characteristic of the Collis LoadaVeyor electrically verated mobile conveyor-elevator, which :an be employed for transferring loads to he vehicle floor from ground level, or to in upper floor to heights of over 12 ft. The boom carrying the conveyor belt can he adjUsted to any angle up to 35 degrees ly a manually operated hydraulic unit Fhe chassis is mounted on rubber casters.

Light Conveyors • The machine is produced by J. Collis ind Sons, Ltd., Regent Square, Gray's Inn Road, London, W.C.1. The concern also inanufacture light-alloy sections of the 1.o1laVeyor gravity-conveyor, the lightxeight. of which is specially advantageous 'or loading goods to the interior of the /Aide; the conveyor can be carried with he load to facilitate handling at the lestination. The range of Collis trucks ncludes machines capable of transportng up to 7 tons.

Special features of the Zephyr ilectrically operated portable conveyors nanufactured by Reynolds and Grayer, _.td., Thomas Street, West Bromwich, nclude a twin-belt conveying mechanism aid the use of hinged sections. These can joined together to increase the effective ength of the unit and to accommodate lifferences in level. If necessary, there'ore, the packages can be moved across higher deck to the same or lower level in the opposite side. The Escaload mrtable conveyor, made by the same iompany, incorporates two sections, one if which can be folded back and attached o support legs. The unit is equipped with ifting bars at one end and is moved in he manner of a conventional barrow.

Delivery up to 7 ft. 3 in. '

Particularly recommended for vehicle oading and for the movement of goodsn-transit depots, the ALM Pacemaker onveyor-elevator manufactured by k. L. Marshall (Carlton), Ltd., near ■ lottingham, can deliver to a maximum ieight of 7 ft. 3 in., whilst the minimum lelivery height is. 2 ft. 7 in. This machine s of the electrically driven-belt type laving a distributed capacity of 2 cwt,: he boom is hydraulically _ operated. ;..nown as the Isilasterveyor, another ALM land conveyor is of the stationary type nd has a capacity of 80 lb. per ft. It is. herefore, particularly suitable for the egular or continuous movement , of eckages between two floors.

Another ALM Mechanical-handling aid .f interest to vehicle operators is a etractable gravity roller conveyor wonted on adjustable stands fitted with asters. Here the particular advantage is he very, small storage space required for he unit when it is not in use. Stacking machines with capacities up to 1,500 lb. and mobile lorry loaders are included, in the Hycaddy and Hydrum equipment built by R. H. Corbett and Co., Ltd., Burgess Hill, Sussex. The Hydrum loaders can be equipped with a mainsor battery-operated electric motor or petrol engine; a hydraulically operated tricycle undercarriage gives easy mobility. The standard models have a capacity of 7. cwt. and can lift this load to a height of 4 ft. 6 in. in 5 seconds.

The makers of the Sholderhi and Onrol tailboard lorry loaders,, A. J. Mackaness, Ltd., Weedon Road, Northampton, recently introduced the Trolliloader, a mobile platform equipped for loading vehicles independently, or transferring goods from one level to another. The platform unit is powered by a 21-h.p.

electric motor or petrol engine and the loadet is attached to the framework. If ,required the same lifting unit can be mounted on the vehicle for occasional work.

When goods arc carried in any type of container, .the return of empties can be a major economic problem. A folding box of lightweight construction which can be mounted on a pallet base to facilitate handling, offers obvious advantages fof the carriage of both specialized and general goods. Such a box is made

by the Granby Box Co., Ltd., 359 Canal Road, Bradford 2, and affords a saving in space of up to 90 per cent.

In its standard form the box comprises plywood panels joined by special steel strip which can withstand repeated flexing without fracturing, and in practice the box.can be folded flat and re-opened over 200 times" before the, steel is liable to fail. Its load capacity is about 3 cwt.

A pallet-based design of the folding box has a rigid softwood base attached to battens and the trunk section, is placed over the •load. This type is particularly suitable forlight machines, such as small industrial. engines and refrigerators.

Light-metal folding containers Of . exceptional strength. are made by Light Alloy Construction, Ltd., Mowden Hall, Darlington.

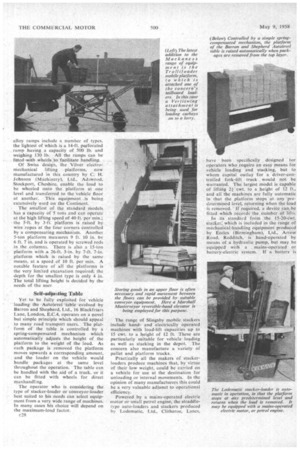

Furniture removers have been the first to appreciate the advantages of the Chairman stair truck for moving relatively heavy loads on narrow stairways and for loading vehicles from ground level.. This simple Manually operated crawler machine was evolved by Chairman, Ltd., 54 Holly Walk, Leamington Spa, and can handle loads up to 500 lb. The crawler tracks are of rubber and can he locked by a cable-operated mechanism controlled by a lever on one of the lifting handles.

Movements on Banks

The movement of crates, containers and pallets across a level deck can be facilitated in so many simple ways that the operator is often faced with a complex problem in determining the best method to employ. At peak periods when a number of vehicles .is being loaded at the same time, it is essential that goods being conveyed to one vehicle should not obstruct the transfer of goods to another. Of equal importance the handling equipment should be sufficiently flexible in its application to obviate time-wasting " change-overs."

Roller gravity-conveyor sections can often be employed to good advantage, but may -obstruct transverse movements; loading with the aid of hand trucks and pallets may be a preferable alternative. Multiplicity of handling aids with regard to Eye may be essential, but should obviously be avoided if multi-purpose equipment can be employed without loss of overall efficiency. The quick movement of one class of goods is uneconomic if it hampers the loading of other goods.

Loading Bogie Simplicity and adaptability are important features of the low-loading bogie known as the Polo Truck, produced by Messrs. Powell and Co., Burry Port, South Wales. The height of the heaviest model, which weighs 38 lb.and has a capacity of 4,500 lb., is only 34in. and the useful space occupied is negligible.

The frame is octagonal and is fitted with two pairs of wheels mounted on ball bearings. The bogie pivots freely on one pair of wheels, and this enables a heavy load to be manceuvred without difficulty. The smallest of the units has a capacity of 700 lb. and measures 19 in by '19 in.

Other Powell handling equipment includes Herculift lifting bars, a particular feature of which is the use of builtin rollers or wheels. One of these bars can be employed for moving lighter cases, and heavy cases can be easily handled with two bars. The largest model has a two-wheeled saddle.

The Powell Vertolifter hand-operated hydraulic elevator truck is made in two models with lifting heights up to 3 ft. Both have a capacity of 500 lb.

A stackable post pallet is included in the many types of standard and special wood pallets produced by Bartlett Materials Handling, Ltd., 227 Holland Park Avenue, London, W.11. It has detachable posts which can be employed to take the weight of an upper pallet. A special pallet known as t& Avon has a projecting superstructure, which enables some types of load to be removed from the pallet by a lift truck and placed on bearers on the lorry, thus obviating difficulties with regard to the return of empty pallets.

, Light-weight stackable stillages with removable posts and stackable box-type stillage, as well as a range of collapsible stillages and industrial trailers and trolleys, are available from P. C. and C. K. Chase, Ltd., Portsmouth Road, Cobham. A simple method of moving pallets without the use of a lifting truck has been provided by M.G.K. Engineering Co., Ltd., Gazette Buildings, Corporation Street, Birmingham, 4. who produce a semi-mobile trolley that can be movet by means of a tug-lift attachment, o alternatively can be fitted with castors An operator's best policy may be t( design a truck to his own requirement before approaching the maker of suet equipment. Many types of truck hay( been produced by Superbuilt Product! Ltd., Bell Works,'Harefield, Middlesex, t( special orders. Although far from beinj of complicated design, they cater effici ently for the highly individual plans o the transport manager. In the concern' standard range of equipment undercar riages of both wood and angle-iron con struction are offered. They are adaptabli to many types of operation. A numbe of box trucks and trolleys is also listed.