A LOW, STRAIGHT-FRAMED SIX-WHEELER.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

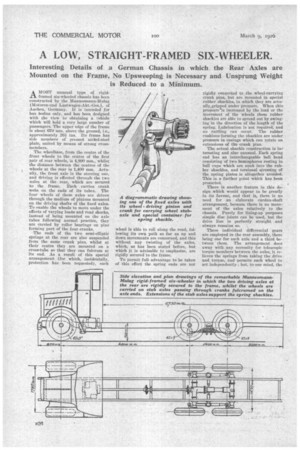

Interesting Details of a German Chassis in which the Rear Axles are Mounted on the Frame, No Upsweeping is Necessary and Unsprung Weight is Reduced to a Minimum.

AMOST unusual type of rigidframed six-wheeled chassis has been constructed by the Mannesmann-Mulag .(Alotoren-und Lastwagen-Akt.-Ges.), of Aachen, Germany. It is intended for bus bodies only, and has been designed with the view to obtaining •a vehicle which will hold a very large number of passengers. The upper edge of the frame is about 070 mm. above the ground, i.e., approximately 26+ ins. Its frame has side members of pressed nickel-steel plate, united by means of strong crossmembers.

The wheelbase, from the centre of the front wheels to the centre of the first pair of rear wheels, is 4,800 mm., whilst the distance between the centres of the wheels at the rear is 1,400 mm. Actually, the front axle is the steering one, and driving is effected through the two axles at the rear, which are secured to the frame. Each carries crank webs on the ends of its tubes. The four wheels of these axles are driven through the medium of pinions mounted on the driving shafts of the fixed axles. To enable the wheels to move under the effects of varying loads and road shocks, instead of being mounted on the axle tubes following normal practice, they are carried by roller bearings on pins forming part of the four cranks.

The ends of the two semi-elliptic springs at the rear are also suspended from the same crank pins, whilst at their centre they are mounted on a cross-tube so that they can fulcrum at its end. As a result of this special arrangement (for which, incidentally, protection has been requested), each wheel is able to roll along the road, following its own path so far as up and down movements are concerned, and this without any twisting of the axles, which, as has been stated before, but which it is advisable to emphasize, are rigidly secured to the frame.

To permit full advantage to be taken of this effect the spring ends are not rigidly connected to the wheel-carrying crank pins, but are mounted in special rubber shackles, in which they are actually.gripped under pressure. When this pressure is increased by the load or the movement of the wheels these rubber shackles are able to spread out by swinging in the direction of the length of the spring. Lubrication is not required; and no rattling can occur. The rubber cushions forming the shackles are under pressure in casings which can rotate on extensionsof the crank pins.

The actual shackle construction is interesting and also unusual. Each spring end has an interchangeable ball head consisting of two hemispheres resting in ball cups which are sunk into the rubber shackles, and torsional stressing of the spring plates is altogether avoided. This is a further point which has been protected.

There is another feature in this design which would appear to be greatly in its favour, and that is, there is no need for an elaborate cardan-shaft arrangement, because there is no movement of the axles relatively to the chassis. Purely for lining-up purposes simple disc joints can be used, but the drive line is perfectly straight and always remains so.

Three individual differential gears are employed in the rear assembly, there being one for each axle and a third between them. The arrangement does away with any necessity for telescopic torque members between the axles, it relieves the springs from taking the drive and torque and permits each wheel to act independently ; but, to our mind, the

outstanding and most important characteristic of the whole design is the great reduction in the unsprung weight. It • may be that the action of a wheel when rising and falling and, consequently, rocking with its crank around the driving pinion, may cause a slowing-down and speeding-up nation, but no doubt this will be compensated for by its differential, The rest of the chassis follows almost normal practice, and, of course, an important point is that the frame, after the first drop close to the dash, is carried in a perfectly straight line to the rear, there being no need for humps over the ,axles, the tubes of which are• carried through holes in the channels.

The engine is a four-cylinder of 125 rem. bore and 150 mm, stroke, developing 58 b.h.p. at 1,000 r.p.ra. The clutch is of the disc type, and the gear box forms a separate unit ; it provides fourspeeds forward and a reverse and is equipped with roller bearings of ample dimensions.

All the wheels are of the Sipplex pattern, with giant pneumatic tyres, 42 ins. by 9 ins., the air for these being obtained from a pump carried directly on the gearbox and with an accessible means of ,control.

Braking is effected by a hand brake acting on the rear wheeLs and a pedal brake which controls the shoes on a transmission drum and in the front wheels. A patent has been applied for in connection with the brake rods fot controlling the brakes on the rear wheels, the arrangement being such that swinging of these wheels does not have any effect on the correct functioning of the brakes. Compensating levers are provided between the brake shaft levers of each of the driving axles. A further compensating lever is arranged between the branches of the brake rod (which lead to the first-mentioned compensating levers) and the chief tension strap of the brake rod. The tension straps take the form of very light, but strong, Steel tapes.

The weight of the chassis is about 4,400 kilos., and the speed about 50 kiloms. per hour, the petrol consumption being 23 kilos, to 25 kilos. per 100 kiloms., and the oil consumption from I kilo. to 1 kilo. for the same distance.