There's more to temperature control than meets the eye

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

by Paul Brockington, hillMech E

Part 1

Many engines are overcooled for a major part of their lives. Engine makers are faced with the problem of producing a system that maintains the best working temperature without overheating in critical conditions.

IN temperate and colder climates, engine overcooling is a more common problem than overheating. But difficulties in the prevention of overcooling are created by the paramount need to prevent overheating in all operating conditions. Significantly, oxidation of the lubricating oil may occur at a lower coolant temperature than that which is satisfactory for heat dissipation from the hottest parts of the engine.

Oxidation produces hot sludge and overcooling produces cold sludge, and each form of sludge tends to block oilways. A detergent additive in the oil holds sludge in suspension in a finely divided state that does not seriously impair its lubricating properties. However, coping with large amounts of sludge results in rapid additive depletion.

The oil of a properly cooled engine has a relatively long life; in practice the oil of an engine operating at the optimum temperature which is not contaminated by dust particles from the atmosphere or by combustion soot has an indefinitely long life.

It can be appreciated. therefore, that accurate control of coolant temperature is strictly related to the control of oil temperatures. And in colder weather, the engine has to supply heat to the driver's cab, and some psv rely on the engine for heating the saloon; in both cases there must be sufficient surplus heat for the purpose and this may depend on cooling-system characteristics.

Temperature control is also related to the noise problem. Fan noise can be and often is a serious source of noise, notably in the case of an engine that operates at a low noise level. Moreover, the trend towards encapsulation of engines to reduce noise will increase the cooling problem, and if encapsulation gains ground, which is likely, cooling packs will probably be developed for location remote from the engine. This development may involve major changes to the vehicle structurally.

The coolant has to be capable of absorbing more than 30 per cent of the heat of combustion to prevent overheating of the combustion chambers, valves, cylinders and pistons. And because the heat produced by combustion is not evenly distributed and the capacity of the main heat paths from the chambers to the coolant (and lubricating oil) varies according to length and configuration of the structure locally, overheating inevitably takes the form of a series of hot spots.

Extracting heat from hot spots has to be done without overcooling other parts of the engine or producing a steep temperature gradient across the block. A steep gradient disiorts the cylinder bores and this increase! blow-by, drag on the piston and the rate o oil dilution, which are unfavourable to lorq life and reliability and may cause seizure.

Keeping the bores round under al conditions of operation (or as near round a! possible) is one of the main targets of at engine designer. If the temperature of tht water in the radiator is much lower than tht temperature of the coolant in the cylindei block, cyclic operation of the thermostai can produce cyclic variations of cylindei block temperatures that repeatedly product steep temperature gradients. This is mon likely (with the best of thermostats) if o high-output water pump is used to product a high rate of coolant flow in hot-spot area to prevent local overheatirig. What is oi special importance is that heat gradients car be increased by air. entrainment in tht system, which can also promote corrosion create hot spots, stall the water pump ant increase coolant loss by excessivt expansion.

Nucleate boiling A water-cooled engine has a particulai advantage over an air-cooled type. If a ho spot causes the water to boil, heat is carriec away by the steam bubbles at a higher ratt than is normally possible by the flow o cooling water because of the latent heal vaporization. As pointed out in a recen I Mech E paper, "Cracking in cast-iroi cylinder heads" by L. W. L. Smith, H. T Angus and A. D. Lamb, what is describe( as nucleate boiling increases the rate a which heat is carried away by the formatim of minute bubbles of steam that are con densed by the coolant in the area.

At higher temperatures, however, thi steam bubbles coagulate which reduce contact with the coolant and the heat trans fey rate is reduced. When the surfacl temperature exceeds 250deg C "filn boiling" occurs and a continuous layer o steam is formed on the hot face, whicl effectively insulates the cooling water fron the hot face and temperature rise can b catastrophic.

The authors recommend that airectional vater flow should be used to reduce tot-face temperatures. They point out that thee-boiling can result from an engine being topped when it has been operating :ontinuously under high load and that .estarting the engine while the coolant is roiling may produce high thermal stresses hat can crack the block. And after-boil can ead to serious loss of coolant. This is a :ommon problem.

Dil-change periods

An efficient system may well double the We of a unit or enable its output to be ncreased by turbocharging or other means without impairing reliability and, as ndicated earlier, it may also enable il-change periods to be safely increased. In )ractice. overcooling when a vehicle is wining light is a frequent fault. Typically he operator is left to his own devices to xpe with the problem by fitting ancillary ;quipment to control radiator temperature. T keeping the radiator warm can be tombined with a saving in fan power so nuch the better.

The engine of a stop-start vehicle has reen known to fail in service after it has )perated a fraction of the mileage covered )y similar vehicles engaged on long-distance work because of piston trouble caused by ion-vaporized acidic products of combusion and cold sludge. In one case the )perator was faced with changing the letergent oil at very short intervals or with itting thermostatically controlled shutters. the use of a controlled fan would have Jeen regarded as a suitable alternative.

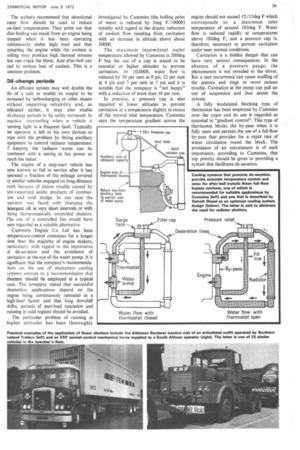

Cummins Engine Co Ltd has been temperature-control conscious for a longer time than the majority of engine makers, particularly with regard to the importance af de-aeration and the avoidance of avitation at the eye of the water pump. It is significant that the company's recommendations on the use of shutterless cooling systems amount to a recommendation that shutters should be employed in a typical case. The company stated that successful shutterless applications depend on the engine being continuously operated at a high-load factor and that long downhill drifts, periods of part-load operation and running in cold regions should be avoided.

The particular problem of running at higher altitudes has been thoroughly investigated by Cummins (the boiling point of water is reduced by 3deg F /1000ft) notably with regard to the drastic reduction of coolant flow resulting from cavitation with an increase in altitude above about 3000ft.

The maximum intermittent outlet temperature allowed by Cummins is 200deg F but the use of a cap is stated to be essential at higher altitudes to prevent cavitation. At 10,000ft, water flow is reduced by 50 per cent at 0 psi, 22 per cent at 4 psi and 7 per cent at 7 psi and it is notable that the company is "not happy" with a reduction of more than 10 per cent.

In practice, a pressure cap is also required at lower altitudes to prevent cavitation at a temperature slightly in excess of the normal inlet temperature. Cummins says the temperature gradient across the engine should not exceed 12 /15deg F which corresponds to a maximum inlet temperature of around 185deg F. Water flow is reduced rapidly at temperatures above 180deg F, and a pressure cap is, therefore, necessary to prevent cavitation under near normal conditions.

Cavitation is a hidden danger that can have very serious consequences. In the absence of a pressure gauge, the phenomenon is not revealed to the driver. But a rare occurrence can cause scuffing of the pistons and rings or more serious trouble. Cavitation at the pump can pull air out of suspension and thus aerate the system.

A fully modulated blocking type of thermostat has been employed by Cununins over the years and its use is regarded as essential to "gradient control". This type of thermostat blocks the by-pass when it is fully open and permits the use of a full-flow by-pass that provides for a rapid rate of water circulation round the block. The avoidance of air entrainment is of such importance, according to Cummins, that top priority should be given to providing a system that facilitates de-aeration.