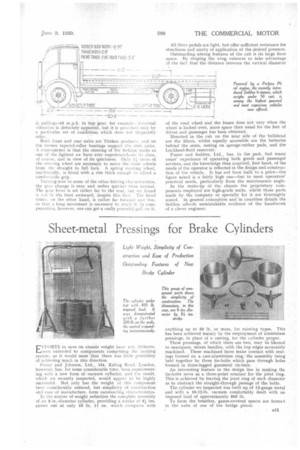

Sheet-metal Pressings for Brake Cylinders

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

Light Weight, Simplicity of Construction and Ease of Production Outstanding Features of New Brake Cylinder EFFORTS to save on chassis weight have not, hitherto, been extended to components comprising the braking system, as it would seem that there was little possibility of achieving much in this direction.

Feeny and Johnson, Ltd., 134, Ealing Road, London, however, has, for some considerable time, been experimenting with a new form of vacuum cylinder, and the result, which we recently inspected, would appear to be highly successful. Not only has the weight of this component been considerably reduced, but simplicity of construction and case of manufacture, form outstanding characteristics.

In the matter of weight reduction the complete assembly of an 8-in.-diameter cylinder, providing a stroke of Si ins. comes out at only 10 lb. 11 oz. which compares with

anything up to 50 lb. or more, for existing types. This has been achieved mainly by the employment of aluminium pressings, in place of a casting, for the cylinder proper.

These pressings, of which there are two, may be likened to saucepans, minus handles, with the top edges accurately machined, These machined faces make contact with seat. lugs formed on a cast-aluminium ring, the assembly being held together by three tie-bolts which pass through holes formed in three-legged gunmetal tie-bars. An interesting feature in the design lies in making thc tie-bolts serve as a three-point retainer for the joint ring. This is achieved by leaving the joint ring of such diameter as to obstruct the straight-through passage of the bolts.

The cylinder we inspected was built up of 12-gauge metal and with a 10-12-lb. vacuum comfortably dealt with an imposed load of approximately 600 lb.

To form the breather, gauze-covered spaces are formed in the webs of one of the bridge pieces.