Americans start noise clamp-down

Page 27

Page 28

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

And give fan clutches the seal of approval

By John Hartley

FAN clutches will get a real boost from the US truck noise regu lations, whereas their main competitors, radiator shutters, seem to• have a bleak future in the USA. The boost stems from the fact that during American noise tests, the clutch is normally disengaged, so the measured noise level does not include fan noise. In adopting this attitude, the legislators have recognised that the use of fan clutches reduces traffic noise, and should therefore be encouraged.

This is in stark contrast to the attitude of our Department of the Environment that vehicles should be tested in the worst condition, irrespective of whether this has any bearing on the noise level of real traffic.

From the British viewpoint, the interesting features of the legislation are the thoroughness of the testing, the adoption of a static test, the reasons for the concession on clutched fans, the penalties for infringement, and the public way in NNhich objections to the legislation are dealt with. Of course, these points are being studied by our legislators as well.

At first sight the US legislative framework seems desperately complicated, because the responsibilities of each government body are limited. Thus, the Environmental Protection Agency (EPA) was responsible for framing the noise legislation, with respect to "best available technology" consistent with the ability of the industry to meet regulations, and taking into account the cost. Then, it was up to the Bureau of Motor Carrier Safety (BMCS) to find a way of implementing the regulations. But before it could do that the BMCS had to publish its intentions, give time for replies and then publish its reactions to the replies. In practice, this means that the BMCS cannot ignore valid objections to its proposals —and that is a situation we could do with in the UK.

Eventually, the regulations took effect on October 15, 1975, and they apply to all vehicles with gross weights of over 4,540kg (10,0001b) used on interstate haulage—each State being responsible for internal matters, it appears. The permitted levels are tabulated, and the important point to note is that they are measured at a, nominal distance of 15.2m (50ft), compared with the 7m of the BS and ISO drive-by tests. Since the noise level decays as it moves away from its source, the level recorded on the US test would be about 5dBA lower than if the same vehicle were tested according to the ISO procedure—their 86dBA being equivalent to our 91dBA, or thereabouts. There are two significant points to these levels : first, they apply to all vehicles, not just new ones ; secondly, they are "in use" measurements, so that equivalent figure of 91dBA should be compared with EEC levels of 94dBA for trucks with engines of over 200bhp, and of 92t1BA other trucks.

To see how much noise levels could be reduced, the US Department of Transportation (DOT) has sponsored various noise reduction programmes, and before treatment, the three vehicles—a White Freightliner Powerliner, •a White Road Commander, and an International tractor with a Detroit Diesel 8V-71 engine—all had noise levels of 88dBA, 2dBA over the new limit. With the addition of 100-2001b of sounddeadening material costing $300-$600 (£150-£300), but without the engine being fully enclosed, noise levels of about 80dBA were recorded, so although the new regulations require some attention, much lower levels can be achieved.

Massive fines or imprisonment

What's more, the BMCS has introduced such severe penalties that these are regulations the truckers cannot afford to ignore. For a first offence of "wilful violation" an operator can face a fine of up to $25,000 (about £12,000) per day, and/ or imprisonment for a year ! For subsequent offences, the penalties can be doubled.

So that the tests can be carried out in many different places with a fair degree of consistency, the BMCS has tried to allow for all circumstances—whether the area is concrete or grassy, for guardrails and so on. Although the basic 'distance from the microphone to the centre-line of the truck is 15.2m (50ft), the noise level can be measured at distances from 10.7m to 25.3m (35ft-83ft), with allowances being made for the differences in distance. For the drive-by tests, the site must include a portion of public "highway," and since a 45m width of substantially flat ground is required, this would be very difficult to find in the UK. In the USA, this presents few problems, and to allow for other traffic, it is specified that the noise level must rise by at least 6dBA, as the truck approaches, and then fall by at least 6dBA subsequently.

Trucks must meet both the drive-by and static tests, but presumably it is up to the testers to decide which test they use, this being dictated to some extent by the space available. The testers, incidentally, are "any agents of the Federal Highway Administration," and they can test vehicles whenever they feel like it—even if the test disrupts schedules. They also have some discretion over tolerances, in that they may accept vehicles that exceed the limit by 2dBA, say, if they feel that the conditions warrant it. On the other hand, if a large number of one operator's vehicles are just, over the limit, that is not. good enough — he must get IT has taken a long time to get our hands on a B-Series ERF for a full CM road test, but the vehicle proved well worth waiting for.

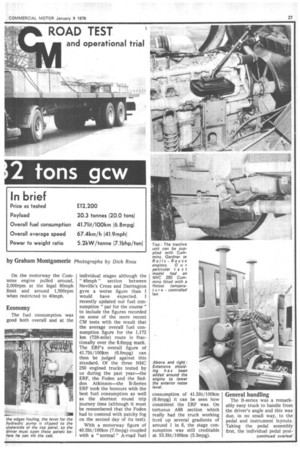

Announced at the Earls Court Show in 1974, the B-Series trucks from ERF comprise two-, threeand four-axle machines using the familiar Cummins, Gardner and Rolls-Royce engine options. The particular model featured in this test was a Cummins 250 engined tractive unit, the official number being 38C2.

The test results were good, with a better than average fuel consumption figure matched to a quick journey time for the 700odd miles operational trial route.

Specification

The major mechanical units making up the ERF's technical specification are too well known to warrant an extensive description, consisting as they do of a Cummins NHC 250 engine driving via a Lipe Rollway clutch and a Fuller gearbox to a double-reduction Kirkstall axle. The cab construction, however, is totally different from the A-Series, or any other ERF for that . matter, and as such deserves a fuller description.

Known as the SP cab, it consists of a 14swg welded steel subframe with covering panels in glassfibre. The panels are prefabricated in hot-pressed SMC (sheet moulding compound) glassfibre and are controlled in size during manufacture to ensure complete interchangeability from the spares point of view. The frame itself is built up from seven main sub-assemblies using both spot and gas welding while the finished component is then rust-proofed via an electrophoretic paint dip. The metal frame carries all the structural rigidity and safety requirements on its own. The plastic panels, in the words of an ERF engineer, "merely keep the weather out."

The engine and transmission match was well thought out on the test truck although second and third were rather too close together for normal road work. So here and there we resorted to skipping a gear. Although the Seddon Atkinson 400 and the ERF use the same nine-speed Fuller gearbox, the nomenclature is slightly different. With the Oldham truck, the box is referred to as a straightforward nine-speed whereas the ERF refers to it as an eightspeed plus crawler. As the two trucks invite comparison by virtue of identical engines and gearboxes (in the form tested by CM) this point must be borne in mind especially when talking about hill performance.

One of the test hills on the CM Scottish route—the long climb up Carter Bar on the Scotland /England border—had the ERF pulling strongly in fifth for most of the climb with a brief drop into fourth near the summit. The Seddon Atkinson, however, fell between two stools in that one gear was too high while the next one was too low, which meant that the 400 also went most of the way up in fifth gear. But this fifth gear is equivalent to fourth on the ERF.

This hill-climbing ability was a good feature of the ERF as far as our route was concerned because I always had the right ratio for the hill in question. There was none of the "too high or too low" gearing problem. On the motorway the Cummins engine pulled around, 2,000rpm at the legal 60mph limit and around 1,500rpm when restricted to 40mph.

Economy

The fuel consumption was good both overall and at the individual stages although the " 40mph " section between Neville's Cross and Darrington gave a worse figure than I would have expected. I recently updated our fuel consumption "par for the course" to include the figures recorded on some of the more recent CM tests with the result that the average overall fuel consumption figure for the 1,172 km (728-mile) route is fractionally over the 6.6mpg mark. The ERF's overall figure of 41.71it/100km (6.8mpg) can then be judged against this standard. Of the three NHC 250 engined trucks tested by us during the past year—the ERF, the Foden and the Seddon Atkinson—the B-Series ERF took the honours with the best fuel consumption as well as the shortest round trip journey time (although it must be remembered that the Foden had to contend with patchy fog on the second day of its test).

With a motorway figure of 40.31it/100km (7.0mpg) coupled with a " normal " A-road fuel consumption of 41.51it/100km (6.8mpg) it can be seen how consistent the ERF was. On tortuous A68 section which really had the truck working hard up several gradients of around 1 in 6, the stage consumption was still creditable at 53.31it/100km (5.3mpg).

General handling

The B-series was a remarkably easy truck to handle from the driver's angle and this was due, in no small way, to the pedal and instrument layouts. Taking the pedal assembly first, the individual pedal posi tions and operating angles were first class. The clutch pedal, for example, had a short travel, but the ERF engineers have not fallen into the old trap of making the clutch takeup too fierce with a small pedal movement. The pedal itself was mounted very low down so there was none of the usual raising the left foot vertically about 2ft before contact could be made.

The instrument panel was angled so that the dial faces were approximately perpendicular to the line of sight of a driver of average height. The dials were exceptionally easy to read with no problems caused by light reflection from the individual faces.

The braking tests were carried out as usual at MIRA, but the light rainfall on the test day had made the track very greasy, which was not exactly In the ERF's favour. Taking the stop from 40mph as an example the truck took just over 100ft to stop, which would beat most of the heavyweights tested by CM during the past year in spite of the slippery surface.

Summary ERF has lost ground to Volvo in the over-28-ton market during this model changeover period in the past 12 months, and the position of top British contender in this category has been taken over by Seddon Atkinson, Now that the ERF factory is turning out the B-series in full production it will be interesting to see if the position will be reversed. Certainly, on the results of our test the ERF is a formidable challenger, combining good fuel economy with the ability to achieve shorter round-trip journey times-and this second point is becoming more and more important.

The new cab has been proved to have the necessary structural strength during tests carried out by ERF and the replaceable panels should be a useful time-saver when compared with the old handlaid-uo-method of glassfibre construction. I think the latest ERF has a good future in front of it.

The Price of the 38C2 model imperial as tested was £12,200.