Ton Saved in Light-metal Cattle Truck

Page 126

If you've noticed an error in this article please click here to report it so we can fix it.

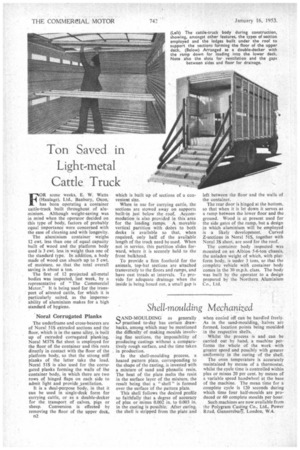

FOR some weeks, E. W. Watts (Haulage), Ltd., Banbury, Oxon,• has been operating a container cattle-truck built throughout of aluminium. Although weight-saving was in mind when the operator decided on this type of body. factors of probably equal importance were concerned with the ease of cleaning and with longevity.

The aluminium container weighs 12 cwt. less than one of equal capacity built of wood and the platform body used is 3 cwt. less in weight than one of the standard type. In addition, a body made of woad can absorb up to 5 cwt. of moisture, so that the total overall saving is about a ton.

The first of 12 projected all-metal bodies was inspected, last week, by a representative of "The Commercial Motor." It is being used for the transport of attested cattle, for which it is particularly suited, as the impermeability of aluminium makes for a high standard of hygiene.

Nora! Corrugated Planks

The underfrarne and cross-bearers are of Nora! 515 extruded sections and the floor, which is in the same alloy, is built up of extruded corrugated planking. Noral M575 flat sheet is employed for the floor of the container and this rests directly in contact with the floor of the platform body, so that the strong stiff planks of the latter take the load. Nora 51S is also used for the corrugated planks forming the walls of the container body, in which there are two rows of hinged flaps on each side to admit light and provide yentilation.

It is a dual-purpose body, in that it can be used in single-deck form for carrying cattle, or as a double-decker for the transport of calves, pigs or sheep. Conversion is effected by removing the floor of the upper deck, 02 which is built up of sections of a convenient size.

When in use for carrying cattle, the sections are stowed away on supports built-in just below the roof. Accommodation is also provided in this area for the loading ramps. A movable vertical partition with dobrs to both decks is available so that, when required, only half of the available length of the truck need be used. When not in service, this partition slides forward, where it is securely held to the front bulkhead.

To provide a firm foothold for the animals, top-hat sections are attached transversely to the floors and ramps, and have cast treads at intervals. To provide for adequate drainage when the inside is being hosed out, a small gap is left between the floor and the walls of the container.

The rear door is hinged at the bottom. so that when it is let down it serves as a ramp between the lower floor and the ground. Wood is at present used for the side gates of the ramp, but a design in which aluminium will be employed is a likely development. Curved Z-sections in Noral 515, together with Noral 35 sheet, are used for the roof.

The container body inspected was mounted on an Albion 5-6-ton chassis, the unladen weight of which, with platform body, is under 3 tons, so that the complete vehicle with container body comes in the 30 m.p.h. class. The body was built by the operator to a design prepared by the Northern Aluminium Co., Ltd.