Shell-moulding Mechanized

Page 126

If you've noticed an error in this article please click here to report it so we can fix it.

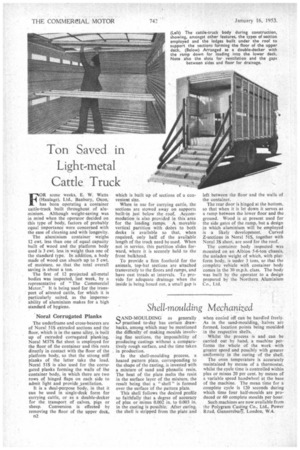

SAND-MOULDING as generally practised to-day has certain drawbacks, among which may be mentioned the difficulty of making moulds involving fine sections, the impossibility of producing castings without a comparatively rough surface, and the time taken in production.

In the shell-moulding process, a heated pattern plate. corresponding to the shape of the casting, is invested with a mixture of sand and phenolic resin. The heat of the plate melts the resin in the surface layer of the mixture, the result being that a " shell" is formed over the surface -of the pattern plate.

This shell follows the desired profile so faithfully that a degree of accuracy of plus or minus 0.002 in. to 0.003 in. in the casting is possible. After curing. the shell is stripped from the plate and when cooled off can be handled freely. As in the sand-moulding, halves are formed, location points being moulded in the respective shells.

Whilst the process is and can be carried out by hand, a machine performs the whole of the work with greater speed and possibly with greater uniformity in the curing of the shell.

The oven temperature is accurately maintained by means of a thermostat, whilst the cycle time is controlled within plus or minus 20 per cent. by means of a variable speed handwheel at the base of the machine. The mean time for a complete cycle is 120 seconds during which time four half-moulds are produced or 60 complete moulds per hour.

Such machines are now available from the Polygram Casting Co., Ltd., Power Road, GunnersburY, London, W.4.