Simple Three-way Gear for

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

Four-wheel Steerers

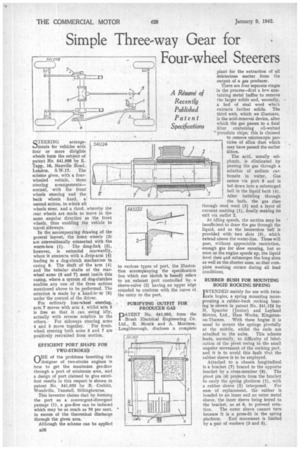

STEERING arrangementsments for vehicles with four or more dirigible wheels form the subject of patent No. 541,098 by E. Tapp, 10, Manville Road, London, SW .17. The scheme gives, with a fourwheeled vehicle, three steering arrangements— normal, with the front wheels steering and the back wheels fixed, a second action, in which all

wheels steer, and a third, whereby the rear wheels are made to move in the same angular direction as the front wheels, thus enabling the vehicle to travel sideways. In the accompanying drawing of the general layout, the front wheels (2) are conventionally connected with the

worm-box (1). The drag-link (3), however, is extended rearwardly, where it connects with -a .drop-arm (4) leading to a dog-clutch mechanism in casing 6. The shaft of the arm (4) and the tubular shafts of the rearwheel arms (5 and 7) meet inside this casing, where a system of dog-clutches enables any one of the three actions mentioned above to be performed. The selection is made by a hand-leer (a) under the control of the driver.

For ordinary four-wheel steering, arm 7 moves with arm 4, whilst arm 5 is free so that it can swing idly, actually with reverse rotation to the others.For sideways steering arms 4 and 5 move together. For frontwheel steering both arms 5 and 7 are positively restrained from motion.

EFFICIENT PORT SHAPE FOR TWO-STROKES

r\NE of the problems besetting the L./designer of two-stroke engines is how to get the maximum gas-flaw through a port of minimum area, and a design of port claimed to give excellent results in this respect is shown in patent No. 541,035 by R. Corbitt, Woodville, Tunstall, Sittingbourne.

This inventor claims that by forming the port as a convergent-divergent passage (I), a gas-flow can be induced which may be as much as 70 per cent. in excess of the theoretical discharge through the given area.

Although the scheme can be applied plant for the extraction of all deleterious matter from the output of a gas producer.

There are four separate stages in the process—first a box containing metal baffles to remove the larger solids and, secondly, a bed of sisal wool which extracts further solids. The third unit, which we illustrate, is the acid-removal device, after which the gas passes to a final filter containing oil-wetted * porcelain chips: this is claimed to remove microscopic partidies of silica dust which may have passed the earlier filters, The acid, usually sulphuric, is eliminated by passing the gas through a solution of sodium carbonate in water. Gas enters via port 6 and is led down into a submerged bell in the liquid bath (4). After bubbling through the bath, the gas rises through steel wool (3) and a layer of coconut matting (1) , finally making its exit via outlet 2.

At idling speeds, the suction may be insufficient to draw the gas through the liquid, and so the immersion bell is provided with two elots (5), which extend above the water-line, These will pass, without appreciable restriction, enough gas for slow running, but so soon as the engine speeds up, the liquid level rises and submerges the long slots as well as the shorter ones, so that complete washing occurs during all load conditions.

F 15

vela ri"

RUBBER BUSH FOR MOUNTING BOGIE ROCKING SPRING INTENDED mainly for use with twin'axle bogies, a spring mounting incorporating a rubber-bush rocking bearing is shown in patent No, 591,124 by. H. Spurrier (Junior) and Leyland Motors, Ltd., Ham Works, Kingston on-Thames. With these bogies it is usual to mount the springs pivotally at the middle, whilst the ends are

attached to the axles. This scheme leads, normally, to difficulty of lubrication of the pivot owing to the small angular movement of the rocking part, and it is to avoid this fault that the rubber sleeve is to he employed.

Attached to a chassis longitudinal is a bracket (7) braced to the opposite bracket by a cross-member (8). The pivot pin (4) projects from the bracket to carry the spring platform (1), with

a rubber sleeve (2) interposed. E'er ease of replacement, the rubber is bonded to an inner and an outer .metal sleeve, the inner sleeve being keyed to the bracket, as at 6, to prevent rota

tion. The outer sleeve cannot turn because it is a press-fit in the spring platform, End movement is limited by a pair of washers (3 and 5).