Ford DIM/Hands Neway air suspension

Page 30

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

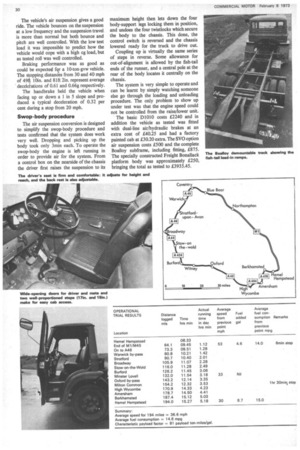

by Gibb Grace; pictures by Dick Ross THE GROWTH in the interest apparent over the past few years in the swop-body system for trunking and delivery vehicles has developed into a greater utilization of this system. Ford, quick to see the potential of this market, now offers as a special vehicle option a rear-axle air suspension which was developed in co-operation with Hands Newsy.

For CM's test a four-wheel 10-ton-gvw D1010 with a Bonallack brewery body was used; it was the one exhibited on the Ford stand at last year's Commercial Motor Show.

The D series cab, a true three-seater, is near perfect for easy entrance; the bottom step is only 17in. off the ground; doors open to 90deg.

I found the driving seat well above average in comfort. Height adjustment is ample and the fore and aft adjustment sliding mechanism worked really smoothly; the back of the seat is adjustable for rake and is well shaped. The whole seat has ample proportions and is firmly upholstered. But I suggest that a breathing fabric should be used in preference to pvc.

Pedal layout is good and the instrument panel simple and to the point. If the vehicle is specified painted, the cab interior comes painted in the body colour and considerably improves the cab interior. The test vehicle colour was Monaco red — a nice contrast to the black dash trim, the black floor covering, the black trim behind the seats and the light-grey roof lining.

Visibility Visibility through the screen is not restricted by the header rail and in bad weather the wipers clear to within lin. of the top of the screen in front of the driver. Bottom-mounted, two-speed electric wipers are fitted as standard together with a very efficient foot-operated washer system. Only light pressure with the left foot gives four high-volume jets (from two points). It was very cold for the performance tests at MIRA and I appreciated the adequate heater which, even though the cab door was continually being opened and closed, kept the cab comfortably warm— an important point for the delivery driver. No under-cab noise insulation was fitted and consequently the interior noise level was higher than we have come to expect from Ford. Interior noise level increased to 86 dBA in third gear, but dropped to a satisfactory 80 dBA at 40 mph in top gear. No readings were taken at maximum speed but increased engine, road and wind noise made the vehicle unpleasantly noisy at top speed. For an appraisal of the chassis we tested the vehicle over CM's 194-mile Midlands test route, which includes a motorway section as well as town and country, and overall performance over this route was excellent. Average speed worked out at 36.6 mph and average fuel consumption at 14.6 mpg. The D1010 is fitted with Ford's own sixlitre, six-cylinder diesel engine, which has a net output to BS AU 141a: 1971 of 103.5 bhp giving just over 10 bhp per ton. This relatively powerful engine gives good performance with Ford's new synchromesh four-speed gearbox, although an improvement could be expected from use of the six and eight-speed boxes which are available as options. The use of a 5.29 to 1 rear axle ratio with the four-speed gearbox gave a top speed of 58 mph and a first gear starting ability of 1 in 5, so obviously the range of performance leaves nothing to be desired. Speeds in the intermediate gears are 8, 18 and 34 mph and on level ground the considerable torque of the six-litre engine (234 lb ft to BS AU 141a: 1971 net) handles the "gaps" without too much effort. Paradoxically, the large gap between third and fourth gear did not prove to be such a problem on the road. On a motorway run from Hemel Hempstead to the end of M45 no gear other than top was used. Average speed for the 64.1 miles was 53 mph and fuel consumption 14.0 mpg. The only steep climb on M1 going north on this section is the climb up from the southern A5 intersection, and the D1010 managed that at 46 mph in top gear. Where the speed dropped below this figure, as for example on the gradient at Watford Gap, the cause was baulking by other traffic and not lack of performance.

Top gear performance

Forty mph could be maintained quite happily in top gear on the level, but even slight gradients needed third gear; once in that gear, however, 30 mph could be held on almost any gradient. At only two points— Broadway Hill and High Wycombe Hill (both about 1 in 8) was second gear needed because of the gradient. This ability to maintain a good speed in top gear is reflected in the fuel consumption and average speed over the "40 mph" section of the route. Fuel consumption worked out at 15.0 mpg for an average speed of 31.8 mph.

The manual steering required more effort than I would have liked in spite of being quite low geared at just over five turns from lock to lock. The low gearing made the steering rather insensitive in the dead-ahead position and this coupled with some kickback from the road wheels produced a rather mediocre combination. Power steering is available as an option on the D1010 at an additional cost of £81.60 and would be useful if a lot of low-speed town work is called for. Turning circle was good at 46ft between kerbs on each lock. The vehicle's air suspension gives a good ride. The vehicle bounces on the suspension at a low frequency and the suspension travel is more than normal but both bounce and pitch are well controlled. With the low test load it was impossible to predict how the vehicle would cope with a high cg load, but as tested roll was well controlled.

Braking performance was as good as could be expected fqr a 10-ton-gvw vehicle. The stopping distan. from 30 and 40 mph of 4911 10in. and 81ft 2in. represent average • decele ations of 0.61 and 0.66g respectively. The handbrake held the vehicle when facing up or down a 1 in 5 slope and produced a typical deceleration of 0.32 per cent during a stop from 20 mph.

Swop-body procedure The air suspension conversion is designed to simplify the swop-body procedure and tests confirmed that the system does work very well. Dropping and picking up the body took only 3min each. To operate the swop-body the engine is left numing in order to provide air for the system. From a control box on the nearside of the chassis the driver first raises the suspension to its maximum height then lets down the four body-support legs locking them in position, and undoes the four twistlocks which secure the body to the chassis. This done, the control switch is reversed and the chassis lowered ready for the truck to drive out. Coupling up is virtually the same series of steps in reverse. Some allowance for out-of-alignment is allowed by the fish-tail ends of the runner, and a central pole at the rear of the body locates it centrally on the chassis.

The system is very simple to operate and can be learnt by simply watching someone else go through the loading and unloading procedure. The only problem to show up under test was that the engine speed could not be controlled from the raise/lower unit.

The basic D1010 costs £2240 and in addition the vehicle as tested was fitted with dual-line air/hydraulic brakes at an extra cost of £40.25 and had a factory painted cab at £30.20 extra. The SVO option air suspension costs £500 and the complete Boalloy subframe, including fitting, £875. The specially constructed Freight Bonallack platform body was approximately £250, bringing the total as tested to £3935.45.