THEORY and DESIGN• of MO[

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

RN PRODUCER-GAS PLANTS

A Review of Available Generators and Their Operating Characteristics. Possible Lines of Development of Producer-gas Engines

flNI their interesting paper, entitled 1." The Modern Portable Gas Producer," which was read before members of the Institute of Fuel on Thursday last, Messrs. Bosworth Goldman and N. Clark Jones deal, not only with the development of the producer-gas plant, but with every phase of the subject of the utilization of producer gas as a fuel for road-transport vehicles.

Although greater use is being made of producer-gas plants on the Continent than in this country, the authors point out that most of the initial development work was carried out in Great Britain, the first portable gasproducer, of English design, being patented by Samuel Brown in 1836. Between 1836 and 1900 little attention • was devoted to the subject, but development received an impetus in 1901, when a patent was taken out for a generator using coke or charcoal as a fuel.

Fuel Problems.

As interest in the design of plant increased, so it was found that the available fuels presented considerable

difficulties. The success of lowtemperature-carbonization processes, about 1926, however, gave an impetus to producer-gas development in Great Britain.

The first recorded French investigation, say the authors, was by Lebon in 1785, although little of a practical nature was done until 1910, when a Paris bus was equipped for operating on producer gas.

During the French military manceuvres, in 1937, a squadron of 140 producer-gas vehicles took part, which goes to show that the French Government takes a lively interest in the subject. The authors -point out that considerable attention has also been given to gas producers in Germany, Sweden and Italy.

After dealing at some length with the theory of converting solid fuels into gas, the authors then proceed to describe the essential features of a generator, the materials used and the various methods of applying the necessary apparatus to a vehicle: B28 As to specific designs of gas producer, the authors designate these as: up draught, down draught, crossdraught, double-draught and doublezone. In the up-draught producer the flow of air and gas is in an upward direction and counter-currentwise to the fuel flow.

From the thermal point of view, say the authors, this type is the best, but for tarry fuels the method entails the necessity of providing effective means for preventing tarry matter from reaching the engine. The following generators are stated by the authors to be of this type :—Wisco, Hansa, Hum boldt-Deatz (German) ; Koela (British) ; Dux (Italian) ; Malbay, C.G.B. (French).

These designs use low-temperature cokes, anthracite and charcoal as fuel. This design of producer, the authors point out, is characterized by giving better quality gas than the downdraught or cross-draught types, and are the easiest for starting ,the engine on gas.

In down-draught producers, the flow of air and gas is in a downward direction and currentivise with the fuel flow. The list of makes Of generator operating on this principle is given by the authors as Koela (British) ; Fiat (Italian) ; Imbert (German) ; Sveland, Graham-Stedts (Swedish) ; Imbert, Panhard, Sabatier, Saga.m, Guillaume, Rustic (French).

These plants mainly use wood charcoal, charcoal briquettes, raw wood,

or tarry fuels. Down-draught producers, say the authors, are charaeterized by their ability to destroy tarry matter and fuel dust, but suffer, to some extent, from uneven thermal balance. Water is not used to any extent with this type of producer, but certain manufacturers claim that charcoal, containing up to 25 per cent, of moisture, can be used with fuel efficiency.

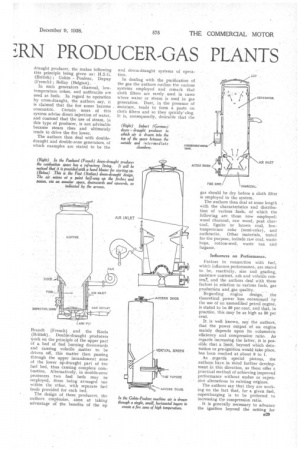

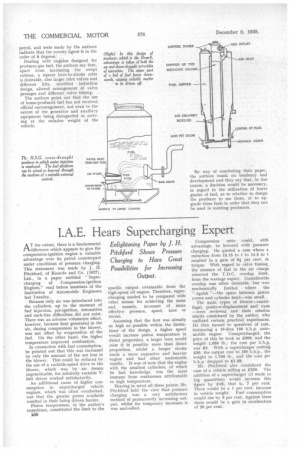

A type which has the commendable merit of simplicity of construction combined with quick starting is the cross draught producer, the makes following this principle being given as: H.S.G. (British) ; Gohin Poulenc, Dupuy (French) t Bellay (Belgian).

In such generators charcoal, lowtemperature cokes, and anthracite are used as fuels. In regard to operation by cross-draught, the authors say, it is claimed that the fire zones become concentric. Certain users of this system advise direct injection of water, and contend that the use of steam, in this type of producer, is not advisable because steam rises and ultimately tends to drive the fire lower.

The authors then deal with doubledraught and double-zone generators, of which examples are stated to be the

Brandt (French) and the Koela (British). Double-draught producers Work on the principle of the upper part of a bed of fuel burning downwards and causing volatile .matter to be driven off, this matter then passing thi-ough the upper incandescent zone of the lower up-draught part of the fuel bed, thus causing complete combustion. Alternatively, in double-zone producers two fuel beds may be employed, these being arranged one within the other, with separate fuel feeds provided for each bed.

The design of these producers, the authors emphasize, aims at taking advantage of the benefits of the up and down-draught systems of operation.

In dealing with the purification of the gas the authors outline the various systems employed and remark that cloth filters are rarely used in cases where water or steam is used in gas generation. Dust, in the presence of moisture, tends to form a paste on cloth filters and so they quickly' clog. It is, consequently, desirable that the gas should be dry before a cloth filter is employed in the system.

The authors then deal at some length with the characteristics and distribution of various 'fuels, of which the following are those now employed: wood charcoal, raw wood, peat charcoal, lignite or brown coal, lowtemperature coke (semi-coke), and anthracite. Other materials, tested fOr the purpose, include raw coal, waste hops, cotton-seed, waste tan and bagasse.

Influences on Performance.

Factors in connection with fuel, which influence performance, are stated to be, reactivity, size and grading, moisture content, ash and volatile conten% and the authors deal with these factors in relation to various fuels, gas pacluction and, gas quality.

Regarding engine design, the theoretical_ power loss occasioned by the use of an unmodified petrol engine, is stated to be 30 per cent, and that, in practice, this may be as high as -50 per cent.

It_ is well known, say the authors, that the power output of an engine mainly depends upon its volumetric efficiency and compression ratio. As regards increasing the latter, it is possible that a limit, beyond which detonation or pre-ignition would take place, has been reached at about to 1.

As regards special pistons, the authors have in mind further development in this direction, as these offer a practical method of achieving improved performance without undue or expensive alterations to existing engines.

The authors say that they are working on the fact that, for a given fuel, supercharging is to be preferred to increasing the compression ratio.

It is generally necessary to advance the ignition beyond the setting for petrol, and tests made by the authors indicate that the correct figure is in the order of 8 degrees.

Dealing with engines designed for producer-gas fuel, the authors say that, apart from increasing the swept volume, a square bore-to-stroke ratio is desirable, also larger inlet valves and different lifts, modified induction design, altered arrangement of valve passages and different valve timing.

The authors point out that the use of home-produced fuel has not received official encouragement, not even to the extent of the generator and auxiliary equipment being disregarded in arriving at the unladen weight of the vehicle. By way of concluding their paper, the authors touch on tendency and development and they say that, in due course, a decision would be necessary, in regard to the utilization of lower grades of fuel, as to whether to design the producer to use them, or to upgrade these fuels in order that they can he used in existing producers.