DEVICES FOR LATHE AND DRILLING MACHINE.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Contributions from Three of Our Mechanic and Driver Readers.

SOME useful fittings for lathes arc described, and illustrated by excellent sketches, in a letter which we have received from," 1F-II.," of Bath. One of the sketches has reference to a useful stop to put on a boring bar which is being used to cut a groove in the side of a bored hole. As a rule this work will be done with the boring bar held in the slide-rest of the lathe. For accurate work some precise and mechanical method of measuring the depth of the groove and ensuring that the correct depth is not exceeded is necessary. Particularly is some fitting of this kind needed in connection with repetition work. such a device is shown in one of the accompanying sketches.

The bar is drilled, as may be seen, immediately behind the hole for the cutter, and a short nim secured in place by a setscrew, is fitted into the hole. The pin must be adjusted to touch the side of the hole when the groove has been cut to the requisite depth, and for this purpose it is merely necessary to set It so that the distance from the end of the pin to the end of the cutter is equal to that required depth. The second hole will also be found useful in case the bar is ever required to bore out a hole which is stepped near the month, or has to be bell-mouthed or rounded at the edge.

Another sketch by " F.H." illustrates how to dispense with the need for a setting gauge on the slide rest when testing the height of a tool point in relation to the centre height of the lathe. All that is needed is that a notch be cut, as shown, out of the corner of the, poppet barrel, leaving a flat ledge, coinciding in height with the lathe centres. When setting the tool it Can be rion up close to this reference surface, or datum level, and set either, exactly level, or slightly

above or below, as the conditions of the work necessitate.

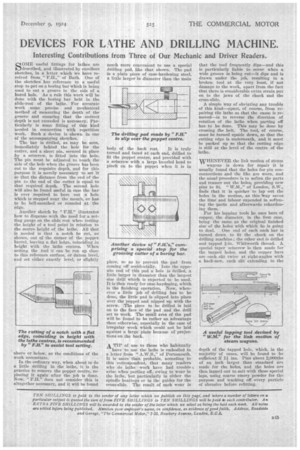

In the ordinary way, when about to do a little drilling in the lathe, it is the practice to remove the poppet centre, replacing it again after the job is done. Now, "FR." does not consider this is altogether necessary, and it will be found much more convenient to use a special drilling pad, like that shown. The pad is a plain piece of case-hardening steel, a little larger in diameter than the main Place, so as to prevent the pad from coming off accidentally. Into the opposite end of this pad a hole is drilled, a little larger in diameter than the largest size drill which is expected to be used. It is then ready for case-hardening, which is the finishing operation. Now, whenever a little job of drilling has to be done, the little pad is slipped into place over the poppet and nipped up with the screw. The piece to be drilled is laid on to the face of the pad and the drill set to work. The small area of the pad will be found to be rather an advantage than otherwise, especially in the case of irregular work which could not be laid against a large plate because of projections on the back.

A TIP of use to those who habitually

have to use the lathe is embodied in a letter from " A.W.S.," of Portsmouth. It is more than probable, according to this correspondent, that many readers who do lathe work have had trouble arise when parting off, owing to wear in the lathe, but particularly in either the spindle bearings or in the guides for the cross-slide. The result of such wear is

that the tool frequently dips—and this is particularly liable to occur when a wide groove is being cut—it dips and is drawn under the job, resulting in a brokeu tool at the very least, if not damage to the work, apart from the fact that there is considerable extra strain put on to the jaws of the chuck and the cross-slide.

A simple way of obviating any trouble of this kind—apart, of course, from repairing the lathe so that the cause is removed—is to reverse the direction of rotation of the lathe when parting off has to be done. This may be done by crossing the belt. The tool, of course, must be turned upside down, so that the cutting edge is underneath, and it must be packed up so that the cutting edge is still at the level of the centre of the lathe.

WHENEVER the link motion of steam wagons is down for repair it is usually found that the holes for pin eon-connections and the like are worn, and the usual procedure is to soften the parts and reamer out the holes, providing new pins to fit. " W.M.," of London, S.W., finds that it is quicker to lap out the holes in the motion, as this tvay saves the time and labour expended in softening the parts and afterwards rehardening them.

For his lapping tools he uses bars of copper, the diameter, in the firstcase, being the same as the original finished size of the holes with Which be is going to deal. One end of each such bar is turned flowrn to tit the chuck on the drilling machine ; the other end is drilled and tapped 1-in. Whitworth thread. A. special taper setscrew is then made for the tapped holes, and the copper bars are each slit twice at right-angles with a hack-saw, each slit extending to the depth of the tapped hole, which, in the majority of eases, will be found to be sufficient if 11 ins. Pins about 2,000ths of an inch larger than standard are made for the holes, and the holes are then lapped out to suit with these special laps, using coarse emery powder for the purpose and washing off every particle of abrasive before refitting.