Tasker' s New Steam Wagon.

Page 2

Page 3

Page 4

If you've noticed an error in this article please click here to report it so we can fix it.

The Most Up-to-date Design and Approved Methods of Construction are Embodied in the Latest Production of the Waterloo Iron Works, at Andover.

Tasker and Sons, LW., of Andover, eidely known in connection with the construction of " Little Giant " steam tractors, is by no means a concern of mushroom growth. So long ago as 1813, the Waterloo foundry first came into existence, and, from its earliest days, it has been intimately associated with the manufacture of all kinds of agricultural machinery, portable engines, and road locomotives, or traction engines. It was amongst the first makers in this country to produce a light steam motor—a miniature traction engine—to come within the limitations of the Motor Car Act of 1890, and since that time " Little Giant " steam tractors have become known in all parts of the world. It was, however, at the recent Royal Show, at Gloucester, that this company made its bow to the steam-wagon section of the community, and the Tasker lorry then shown embodied most of those features which long years of experience, both by makers and users, have shown to be essential in the construction of a steam wagon intended for real hard service.

We were greatly impressed with the design of the first Tasker lorry, and at once sought for an opportunity to examine its details, and ascertain for ourselves of what load and speed it was capable, under average road conditions. It is true that the machine which was shown at Gloucester had a positive type of steering gear that could be operated either by the driver or his mate, or, should the exigencies of the road surface demand it, by both at the same time,,but that form of steering gear wa,s for a special case only, and its perpetuation, as a standard feature, was never contemplated by this maker, who strongly, and rightly, advocates the use of a crossed-chain form of steering as the standard.

By the courtesy of Mr. G. Hoare, the managing director of Wm. Tacker and Sons, Ltd., a member of our Editorial staff has now had an opportunity to examine one of the latest Tacker steam wagons, at the Andover works, where each part was exposed for his inspection, and the working drawings laid before him for examination and criticism. The wagon is one of the " traction" type, in which the locomotive boiler forms part of the chassis. The engine is mounted on the boiler shell, and either of two toothed pinions transmits motion to a meshing wheel On an intermediate shaft, and thence, the drive is taken, through a single chain, to a live back axle. The boiler, which is fitted with a firebox of the Belpaire type, is somewhat shorter than those fitted on the " B2 " type of " Little Giant" tractor, but it is of larger diameter, and has a slightly-greater amount of heating surface. The barrel is 24.1 in, in diameter and, between the tube plates, 48 tubes are fitted ; each of these is 30 in. long by 11 in. in external diameter. The total heating surface amounts to 70 sq. ft., of which total the firebox accounts for 181 sq. ft. The fire grate has an area of 3 sq. ft. All the rivet holes in the boiler plates are drilled in position, and the seams are double riveted. The materials of which the boiler is made are of unimpeachable quality, and a working pressure of 200 lb. per square inch may safely and easily be maintained. Two injectors are fitted for the supply of feed water and, in addition, a steam-driven plunger pump may be added, if specified by

the purchaser. All other usual and necessary boiler mountings, of the highest quality, are provided.

The compound engine has its two cylinders cast in one piece, together with a large live-steam jacket, a receiver, and regulator-valve chamber. The diameters of the cylinders are : high-pressure, 41 in.; low-pressure, 61 in. Both pistons have a stroke of 7 in. Plain " D " valves are fitted, and these are actuated by Stephenson link motion. The engine is capable of developing from 25 h.p.

to 30 h.p., at 340 r.p.m. It should he noted that the valves on this engine are placed on the sides of the cylinders and not on the top as is the practice of this maker for all its compound tractors. High-pressure steam may be admitted to both cylinders simultaneously, and, by means of valves operated by a single lever, each cylinder has a separate exhrmst. The valves and levers are so arranged that either cylinder may be worked independently in case of the breakdown of the other one.

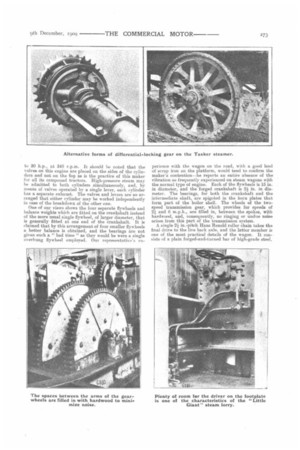

One of our views shows the four separate flywheels and balance weights which are fitted on the crankshaft instead of the more usual single flywheel, of larger diameter, that is generally fitted at one end of the crankshaft. It is claimed that by this arrangement of four smaller flywheels a better balance is obtained, and the bearings are not given such a "bad time" as they would be were a single overhung flywheel employed. Our representatives ex perience with the wagon on the road, with a good load of scrap iron on the platform, would tend to confirm the maker's contention—he reports an entire absence of the vibration so frequently experienced on steam wagons with the normal type of engine. Each of the flywheels is 15 in. in diameter, and the forged crankshaft is 2-1in. in diameter. The bearings, for both the crankshaft and the intermediate shaft, are spigoted in the horn plates that form part of the boiler shell. The wheels of the twospeed transmission gear, which provides for speeds of 2i and 6 m.p.h., are filled in, between the spokes, with hardwood, and, consequently, no ringing or undue noise arises from this part of the transmission system.

A single 2i in.-pitch Hans Renold roller chain takes the final drive to the live back axle, and the latter member is one of the most practical details of the wagon. It consists of a plain forged-and-turned bar of high-grade steel, 41 in. in diameter, and its freedom from changes of section is a most commendable example of practical design. The axle is provided with phosphor-bronze bearings and oonstant lubrication is effected by weans of oiling rings. The axle has a bevel-type differential gear of the usual

pattern, with three planetary bevels, but, on the member which carries the three small bevels, a drum may be cast, as an integral part, and, within this drum, two shoes, which to the axle, may be caused to expand by means of right-and-left-hand screws. We illustrate this very practical form of differential-locking gear; it may be operated, by means of a suitable arrangement of rods and levers, front the driver's seat. Although costing rather more than a positive locking device, consisting of an arrangement of driving pins, this form of differential lock would he found of great service where much soft ground has to be traversed ; it is not fitted on standard vehicles, but its great usefulness would often warrant the extra cost which its fitting entails. The standard back axle embodies the simple but porritive lock illustrated side by side with the view of the friction-grip type.

In all other respects, the design of the 'maker live axle is equally meritorious. Long bearing springs, of ample ,:ection, carry the load with .an ease that is not always attained, even on the most up-to-date steam and petrol lorries of equal load capacity, and it must be admitted that the steady running thereby secured is of real value in practice, equally as regards strain upon the men, wear and tear, and fuel and water consumptions.

It is not generally known that this company is well C quipped for the making of traction-type steel wheels, hut, as a matter of fact, it 8upplies a large number to the trade, annually, and these appear to give entire satisfaction to their users. Those fitted on the Ta,sker wagon are made in accordance with the following dimensions:— drivers, 42 in. in diameter, with " T " section rims 10 in. wide, and 16 steel spokes; whilst the leaders have 12 spokes are 33 in. in diameter, and have a 6 in. tire.

This wagon, by reason of the arrangement which permits of the driver's being situated at one side of the boiler, has a very short wheel-base ; the distance between the axles is lIft. 8 in. The load platform is 11ft. long, by 7 ft. wide, and the overall length of machine is 19 ft. 3 in Its extreme width is 7 ft. 3th., whilst the overall height is 8 ft. 6in.

Coal, coke, or other suitable fuel may be consumed ithin the furnace, and the bunkers can accommodate 4 cwt. of the first-named fuel. The standard water tank has a capacity of 160 gallons, but tanks of greater capecity may be fitted, when desired. The unladen weight of the vehicle is 4 tons 1 cwt., and it is capable of taking an imposed load of six tons, with a further load of three tons on a trailer.