Getting into the construction se or on tipper cuties needn

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

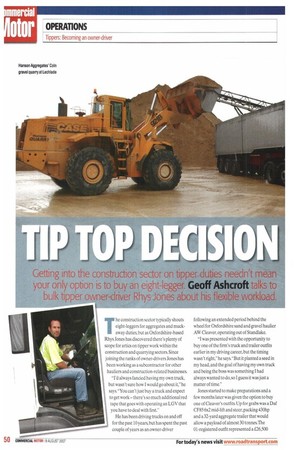

your only option is to buy an eight-legger. Geoff Ashcroft talks to bulk tipper owner-driver Rhys Jones about his ilexe vvorklOac

The construction sector typically shouts eight-leggers for aggregates and muckaway duties, but as Oxfordshire-based Rhys Jones has discovered there's plenty of scope for artics on tipper work within the construction and quarrying sectors. Since joining the ranks of owner-drivers Jones has been working as a subcontractor for other hauliers and construction-related businesses.

"I'd always fancied having my own truck, but wasn't sure howl would go about it," he says. "You can't just buy a truck and expect to get work — there's so much additional red tape that goes with operating an LGV that you have to deal with first."

He has been driving trucks on and off for the past 10 years, but has spent the past couple of years as an owner-driver following an extended period behind the wheel for Oxfordshire sand and gravel haulier AW Cleaver, operating out of Standlake.

"I was presented with the opportunity to buy one of the firm's truck and trailer outfits earlier in my driving career, but the timing wasn't right," he says."But it planted a seed in my head, and the goal of having my own truck and being the boss was something I had always wanted to do, so I guess it was just a matter of time."

Jones started to make preparations and a few months later was given the option to buy one of Cleaver's outfits. Up for grabs was a Daf CFS5 6x2 mid-lift and steer, packing 430hp and a 32-yard aggregate trailer that would allow a payload of almost 30 tonnes.The 01-registered outfit represented a £26,500 investment, "Buying the truck was the easy bit —I also needed an 0-licence and a Certificate of Professional Competence (CPC), plus a helping hand from the bank,says Jones. He invested in a five-year 0-licence and used Classic Transport in St Albans to act as transport manager and CPC holder.

As the owner of a Cleaver outfit Jones was given regular work as a subbie providing traction for the company.In return, the firm took a percentage off the work provided.

Being versatile Unlike traditional sand and gravel-based operators, he decided to steer clear of eightleggers in favour of something a bit more versatile. "You're never stuck for work with an artic— if the bulk tipper work suddenly dries up, you can always pull a flat, curtainsider or skeleton," he says."It's not quite that easy when you've bought a specialist eight-wheeler with an asphalt body, for example. And those are pretty expensive motors to buy too." Fortunately, the work came in steadily and within a good local area, meaning that nights out were few and far between, which suited Jones who has a young family.

Buying the truck and trailer outfit was a good step onto the owner-driver ladder, but after two years and a further 200,000km on top of the CF's already hard-earned 400,000km, he faced some hefty repair bills, which prompted a serious rethink on his truck ownership policy.

"I got my fingers burnt with more than my fair share of breakdowns," he says. "Over the course of a few months, the turbo failed, the camshaft went, the CF needed new heads and a new compressor. It cost me thousands. I liked the Daf, it was a nice truck to drive,but perhaps this one was ready for lighter duties."

In a bid to contain his operating costs Jones looked at truck hire and a deal with MV Commercials in Scotland brought him a 480hp 6x2 Daf XF95 on full repair and maintenance. "All I need to do is insure the truck, put diesel in the tank and give it a clean," he says. "MV takes care of breakdowns, road tax, tyres, all 110.

maintenance requirements and six-weekly inspections — for which I pay a fixed price of £340 per week, which helps to stabilise my cash flow and budgeting."

However, shortly afterwards one of the plants he delivered to closed, some of the work eased off and he was forced into a rethink to top up the workload. Having known Simon Sayers of Berkshire-based Falkland Haulage, Jones went in search of additional tipper opportunities as one of Sayers' subcontractors. Falkland's business revolves around the haulage of aggregates, coal and grain, and with owner-drivers such as Jones, operates several vehicles within a business built on providing reliability and service.

Jones's only drawback was his aggregate trailer."I was a bit limited as to what! could haul with a specialist aggregate trailer," he says. "It wouldn't hold enough bulk when it came to lighter materials such as grain or coal, so the trailer had to go."

He opted for a second-hand 65-yard triaxle United Trailer, equipped with a Wilcox body and PM onboard weighing equipment, carried on SAF axles with disc brakes."I was considering a rib-sided bulk tipper as they're probably the lightest bulkers available and give a great payload potential, though they're not as aerodynamic as the smooth-sided plank trailers, which seemed to be a more sensible choice with fuel efficiency in mind," he says. And with a weekly diesel bill of £800,fuel efficiency was a key consideration.

However, a lack of choice on the market and the pending workload with Falkland Haulage meant Jones had to take what was available; the 65-yard, smooth-sided United Trailer was bought for £13,000. His purchase has carried all manner of bulk materials including aggregates, coal, grain and brewery byproducts. Payment is per tonne carried, with an allowance built in for local or longer distances, meaning that payload is everything.

"Running on six axles, I can get 29 tonnes on board, but it would be great to get an extra half tonne or more with each load — over the course of a year, it would make quite a difference to the bottom line," says Jones.

He has now realised his dream of becoming an owner-driver, but has no plans to run additional trucks. "I can see how others do it quite successfully with subcontractors — it avoids having capital tied up in equipment, and if the work suddenly dries up, you're not paying for a truck that's stood down," he says. "But buying another truck and employing a driver is not for me."

Expansion plans His next logical step is to streamline and improve upon what he already has. Getting his own CPC is a future consideration that would help reduce his monthly expenditure.

Trimming weight is another consideration and Jones reckons that while alloy wheels will give him the potential to haul a few hundred more kilos, the costs don't yet stack up."While they'll look nice, [they] won't put enough on the bottom line," he says."Maybe it's time to look much more closely at tractor choices too."

His current tractor is a 410hp MAN TGA, a temporary stand-in from MV while his regular ride, an XF95, gets a suspension problem rectified. Despite his favouritism towards the Dutch-built marque, his luck with Daf suggests he could be destined to drive another make. "I've had the MAN for just over six weeks and it's not a patch on the XF," he says."While both might be similar on fuel, at 7.5mpg, the MAN gives away power, comfort, living space, aerodynamics and braking power to the XF's Spacecab and 480hp engine.

"With a retarder on board, the Daf could be driven in a way that kept the use of service brakes to a minimum, such was its retardation power -and with my own trailer behind, that's good news for my tyres and brake life. In front of my trailer,thisTGA looks woefully inadequate, where the larger XF with Spacecab and wind kit was a more streamlined package and looked more the part with my bulk trailer.

For all the hard work put in, you might as well enjoy what you do and look after yourself with a comfortable, clean and tidy cab. I've no desire to drive an old cheap shed around just to get an extra half tonne in the trailer -and working for another haulier it's important that my equipment choices help me to stay reliable and dependable to ensure I get regular work."

Jones is pleased with the variation he now gets on bulk tipper work and averages three loads a day, spending the minimum amount of Lime running empty. "For me,this is far more appealing than being a franchised driver with an aggregates firm.The risks are different, hut I enjoy the freedom of being in control and being out and about, not doing the same journeys day in, day out."

The challenge, he says, is to deal with each set of unloading circumstances in a different way. " Every site requires a different thought process for tipping. Some locations are onhighway. others are off-highway,some are into bins and con veyors,which can be timeconsuming, others are simply stockpiled."

The downside is that his travelling radius has increased, which means more nights away. But on balance, he's happier keeping his truck working rather than wondering where the next load is coming from. •