SAVE TIME WITH A KIT

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

German operators are already using kit-based vehicles for 90% of their entire fleets. In Britain the figure is nearer 20% but this sector of the market is growing, thanks to the likes of Cargovan

• In the eyes of Technical Panel Industries the British bodybuilding industry is slowly being deskilled due to the need to cut costs and time at the production stage.

To replace the skill element the proportion of kit bodies, estimated to be about 20% of the total CV parc, will grow when times are hard enough through the efforts of such companies as Ingemex, Lawrence David, Motormaster, Besco, Hawson Garner and Cargovan.

In Europe the figure is much higher than in the UK and in Germany, for instance, 90% of all commercial vehicles are said to utilise kit-based bodies.

Last October Cargo Van Equipment Ltd, realising a stock deficiency of about .2600,000, ended in receivership. The remaining assets were purchased by Technical Panel Holdings and trading commenced under the new name of Cargovan Ltd out of the existing plant at Bridgend.

About half of Cargovan's output of over 2,000 kits per year is in aluminium with the rest in GRP. With a turnover of about £7.5 million TPI is Europe's largest producer of GRP composite panels for commercial vehicle bodies and the company's concern for Cargovan's future was not wholly altruistic. More than 11% of TPI's production is taken up by Britain's kit body market leader.

The company's range includes refrigerator, dry freight and dropsides in sizes up to the maximum permitted length. The majority use the Cargovan Snap-Lok system where the panels are joined by aluminium extrusions which lock together. It was first employed in the USA some 20 years ago before being introduced into Europe where kit body factories were set up in Antwerp, Pans and at Bridgend. Today there is still liaison between these companies and by agreement Cargovan does not sell into Europe.

Cargovans sell only to bona fide bodybuilders and out of some 300 potential customers about 25 are dedicated kit builders.

In addition to normal deliveries by the company's own articulated box vans, assembled spares orders are sent by TNT Overnite so the builder is able to reduce his stockholdings to a minimum. As a rule of thumb it takes about 20 minutes per 30cm run to assemble an aluminium kit but it takes slightly longer for GRP kits which require more holes to be drilled. This means that the bodybuilder can have the kit built and sold and may even have been paid by the time he pays for the kit himself. Perhaps the greatest benefit is the unfailing quality, standardisation and the availability of a full back-up service.

Since 1970 every body has been plated and issued with a serial number and each individual specification recorded so that damaged parts can be replaced quickly to match the existing assembly.

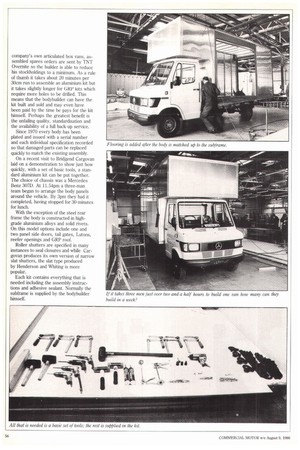

On a recent visit to Bridgend Cargovan laid on a demonstration to show just how quickly, with a set of basic tools, a standard aluminium kit can be put together. The choice of chassis was a Mercedes Benz 307D. At 11.54pm a three-man team began to arrange the body panels around the vehicle. By 3pm they had it completed, having stopped for 30 minutes for lunch.

With the exception of the steel rear frame the body is constructed in highgrade aluminium alloys and solid rivets. On this model options include one and two panel side doors, tail gates, Lutons, reefer openings and GRP roof.

Roller shutters are specified in many instances to seal closures and while Cargovan produces its own version of narrow slat shutters, the slat type produced by Henderson and Whiting is more Popular.

Each kit contains everything that is needed including the assembly instructions and adhesive sealant. Normally the subframe is supplied by the bodybuilder himself.