Thames Bus for Stage Service

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

—And New Light-alloy Meat Van with ingenious Tailboard and Door Linkage

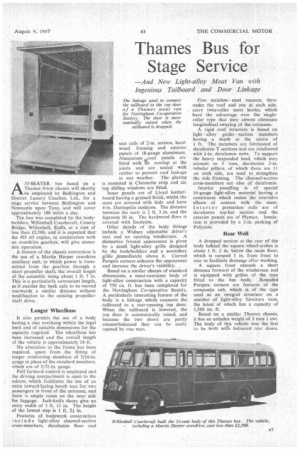

A33-SEATER bus based on a Thames 4-ton chassis will shortly be employed by Bedlington and District Luxury Coaches, Ltd., for a stage service between Bedling ton and Newcastle upon Tyne, and will cover approximately 180 miles a day.

The bus was completed by the bodybuilders, Willenhall Coachcraft,. County Bridge, Willenhall, Staffs, at a cost of less than £2,500, and it is expected that the 4D oil engine, in conjunction with an overdrive gearbox, will give economic operation.

A feature of the chassis conversion is the use of a Martin Harper overdrive auxiliary unit, to which power is transmitted from the gearbox through a short propeller shaft, the overall length of the assembly being about 1 ft. 7 in. This is a particularly convenient length, as it enables the back axle to be moved rearwards a similar distance without modification to the existing propellershaft drive.

Longer Wheelbase It also permits the use of a body having a rear overhang within the legal limit and of suitable dimensions for the capacity required. The wheelbase has been increased and the overall length of the vehicle is approximately 24 ft.

No alteration to the frame has been required, apart from the fitting of longer reinforcing members of 3/16-in. gauge in place of the standard members. which are of 5/32-in. gauge.

Full forward control is employed and the driving compartmeht is open to the saloon, which facilitates the use of an extra inward-facing bench seat for two passengers in front of the entrance, and there is ample room on the near side for luggage. Jack-knife doors give an entry width of 1 ft. 11 in.. The height of the lowest step is 1 ft, 2f in.

Features of bodywork construction i n.c lude light-alloy channel-section cross-members, clurainmin floor and seat rails of 2-in. section, hardwood framing and exterior panels of 18-gauge aluminium. Aluminium • roof panels are fitted with an overlap at the joints and are sealed with rubber to prevent roof leakage in wet weather. The glazing is mounted in Clatonrite strip and six top sliding windows are fitted.

Inner panels are of Lloyd leatherboard having a grained finish, whilst the seats are covered with hide and have 4-in. Dunlopillo cushions. The distance between the seats is 2 ft. 3 in. and the legroom 10 in. The hardwood floor is covered with linoleum.

Other details of the body fittings include a Widney adjustable drivers seat and an opening windscreen. A distinctive frontal appearance is given by a small light-alloy grille designed by the bodybuilders and a secondary grille ,immediately above it. Curved Perspex corners enhance the appearance and increase the driver's visibility.

Based on a similar chassis of 'standard dimensions, a meat-container body of light-alloy construction with a capacity of 750 Cu. ft. has been completed for the Nottingham Co-operative Society. A particularly interesting feature of the body is a linkage which connects the tailboard to a rear-opening top door. When the tailboard is lowered, the top door is automatically raised, and because the two doors are partly counterbalanced they can he easily opened by one man.

Five stainless steel runners, three under the roof and one at each side, carry twin-roller me-at hooks, which have the advantage over the singleroller type that they almost eliminate longitudinal swaying of the carcasses.

A rigid roof structure is based on light alloy girder section members having a depth at the centre of 1 ft. The members arc fabricated of duralumin T sections and are reinforced with fin. duralumin webs. To support the heavy suspended load, which may amount to 5. tons, duralumin 2-in. tubular pillars, of which there are 11 on each side, are used to _strengthen the side framing. The channel-section cross-members are also of duralumin.

Interior panelling is of special 16-gauge light-alloy material having a constituent which resists the corrosive -effects of contact with the meat.

In protection rails are of duralumin top-hat section and the exterior panels are of Plymax. Insulation is provided by a 2-in, packing of Polyzote.

Rear Well

A dropped section at the rear of the body behind the square wheel-arches is about 1 ft. 2 in. below the main floor, which is ramped 5 in. from front to rear to facilitate drainage after washing.

A square front extends a short distance forward of the windscreen and is equipped with grilles of the type fitted to the bus body. Rounded Perspex corners are features of the composite cab, which is of the type used as an integral structure on a number of light-alloy, furniture vans, the latest of which has a capacity of 1,560 cu. ft.

Based on a similar Thames chassis, it has an unladen weight of 3 tons 1 cwt. The body of this vehicle was the first to be built with balanced rear doors.