The Possibilities of Altei native Suspension Systems

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

Developments in Independent Suspension on Private Cars Lead to Interesting Possibilities in the Application of New Ideas to Commercial-vehicle Springing

AN outstanding feature of the Olympia Show for private cars, held last year, was the large increase in the number of manufacturers who have broken away from convention in respect of the suspension system. Many makers have adopted independent springing at the front of the vehicle and, in several cases, this system is also applied to the rear.

This development is the outcome of efforts to improve the riding comfort without, at the same time, affecting the steering or stability of the machine, particularly t high speeds. Such improvement in the riding qualities of the private car is of equal importance in the design of commercial vehicles for the transport of both passengers and goods, and it is, therefore, of interest to examine certain of the principles involved, hearing in mind the possibility of the use of similar systems on business motors.

With the conventional private-car system it is necessary that the front springs should be of greater stiffness than those at the rear, to provide stability of steering and freedom from wheel wobble. With the independent system, however, it is possible to level up, to a great extent, the spring periodicities fore and aft, thereby reducing pitching.

In the consideration of vehicle suspension, periodicity is a convenient measure of spring stiffness in relation to the load carried. Experiments have revealed that a period in the order of 80 per minute is the most comfortable for passengers, and is the most practical for goods transport.

The fact, however, that the loading on the springs varies greatly according to the load on the vehicle makes the• provision of a constant-periodicity systetn a matter of some difficulty. In the conventional layout, the general use of progressive-type springs at the rear is evidence of an effort to increase the rate of the springs as the deflection increases.

The problem of providing conventional leaf springs. having a periodicity in the order of 80, at the front of the vehicle is, of course, even more difficult of solution, for the .reasons previously mentioned. The adoption of inde pendent springing at the front does, however, enable this to be done, and by the provision of either an independent system or progressive-type leaf springs at the rear—to take care of load variations—the resultant levelling up of the spring periodicities all round should make for more comfortable riding characteristics under all conditions.

Whether it is desirable that the independent system should be applied to the rear wheels as well as to the front is a point at which many designers are still at variance. The majority of manufacturers employing the independent system apply it only to the front, but several reputable concerns market machines in which only the rear wheels are independently sprung, others using the system on all four wheels.

On this point it would seem that

independent suspension offers bigger advantages at the front, whilst the difficulties of applying it to the rear are greater in SG far as the transmission arrangements are concerned.

In the application of an independent system, where the periodicity of the suspension has been lowered to increase riding comfort, attention must be paid to the question of

rolling. The tendency to roll on corners is, Of coarse, increased, and some method of counteracting this tendency mast be employed. In many instances, this is effected,by the use of a transverse torsion bar.

Wide variations in design are possible with an independent system of suspension and a number of examples

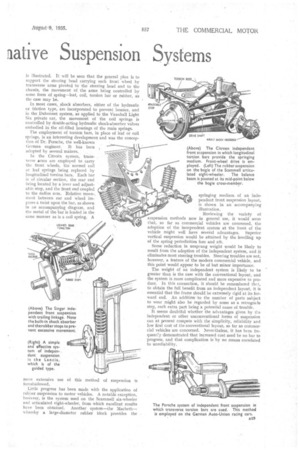

is illustrated. It will be seen that the general plan is to support the steering head carrying each front wheel by transverse arms pivoted to the steering head and to the chassis, the movement of the arms being controlled by some form of spring—leaf, coil, torsion bar or rubber, as the case may be.

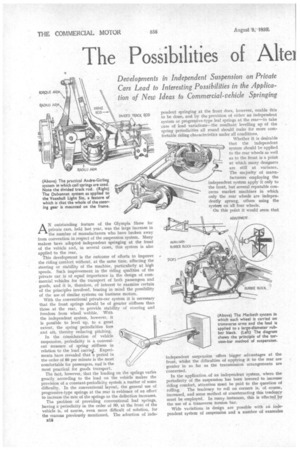

In most cases, shock absorbers, either of the hydraulic or friction type, are incorporated to prevent bounce, and in the Dubonnet system, as applied to the Vauxhall Light Six private car, the movement of the coil springs is controlled by double-acting hydraulic shock-absorber valves embodied in the oil-filled housings of the main springs.

The employment of torsion bars, in place of leaf or coil springs, is an interesting development and was the conception of Dr. Porsche, the well-known German engineer. It has been adopted by several makers.

In the Citroen system, transverse arms are employed to carry the front wheels, the normal coil or leaf springs being replaced by longitudinal torsion bars. Each bar is of circular section, the rear end being located by a lever and adjustable stop, and the front end coupled to the radius arm. Relative move-, merit between ear and wheel imposes a twist upon the bar, as shown in an accompanying diagram, and the metal of the bar is loaded in the same manner as is a coil spring. A

more extensive use of this method of suspension is foreshadowed.

Little. progress has been made with the application of rubber suspension to motor vehicles. A notable exception, however, is the system used on the Scammell six-wheeler and articulated eight-wheeler, from which excellent results have been obtained. Another system—the Macbeth— whereby a large-diameter rubber block provides the

springing medium_ of an independent front suspension layout, is shown in an accompanying illustration.

Reviewing the variety of suspension methods now in general use, it would seem that, so far as commercial vehicles are concerned, the adoption of the independent system at the front of the vehicle might well have several advantages. Superior vertical suspension would be attained by the levelling up of the spring periodicities fore and aft.

Some reduction in unsprung weight would be likely to result from the adoption of the independent system, and it eliminates most steering troubles. Steering troubles are not, however, a feature of the modern commercial vehicle, and this point would appear to be of but minor importance.

The weight of an independent system is likely to be greater than is the case with the conventional layout, and the system is more complicated and more expensive to produce. In this connection, it should be remembered the t, to obtain the foil benefit from an independent layout, it is essential that the frame should be extremely rigid at its forward end. An additionto the number of parts subject to wear might also be regarded by some as a retrograde step., each extra part being a potential cause of trouble.

It seems doubtful whether the advantages given by the independent or other unconventional forms of suspension can at present compete with the simplicity, reliability and low first cost of the conventional layout, so far as commercial vehicles are concerned. Nevertheless, it has been frequently demonstrated that increased cost need he no bar to progress, and that complication is by no means correlated to unreliability.