Controlling engine temperature, 6

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

FITTED BY SOME and approved by most UK heavy vehicle manufacturers, the Dynair Thermo Fan Clutch System provides positive control over the fan drive so that the fan does • not operate as long as the engine coolant temperature remains at, or below optimum level. It is estimated that the fan need only be driven for two to three per cent of vehicle operating time.

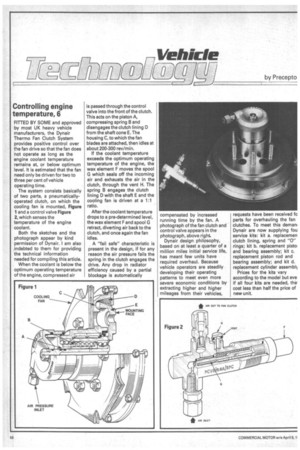

The system consists basically of two parts, a pneumaticallyoperated clutch, on which the cooling fan is mounted, Figure 1 and a control valve Figure 2, which senses the temperature of the engine coolant.

Both the sketches and the photograph appear by kind permission of Dynair. I am also indebted to them for providing the technical information needed for compiling this article.

When the coolant is below the optimum operating temperature of the engine, compressed air is passed through the control valve into the front of the clutch. This acts on the piston A, compressing spring B and disengages the clutch lining D from the shaft cone E. The housing C, to which the fan blades are attached, then idles at about 200-300 rev/min.

If the coolant temperature exceeds the optimum operating temperature of the engine, the wax element F moves the spool G which seals off the incoming air and exhausts the air in the clutch, through the vent H. The spring B engages the clutch lining D with the shaft E and the cooling fan is driven at a 1:1 ratio.

After the coolant temperature drops to a pre-determined level, the wax element F and spool retract, diverting air back to the clutch, and once again the fan idles.

A "fail safe" characteristic is present in the design, if for any reason the air pressure fails the spring in the clutch engages the drive. Any drop in radiator efficiency caused by a partial blockage is automatically compensated by increased running time by the fan. A photograph of the fan clutch and control valve appears in the photograph, above right.

Dynair design philosophy, based on at least a quarter of a million miles initial service life, has meant few units have required overhaul. Because vehicle operators are steadily developing their operating patterns to meet even more severe economic conditions by extracting higher and higher mileages from their vehicles,

*

requests have been received fa parts for overhauling the fan clutches. To meet this dement Dynair are now supplying fou service kits: kit a. replacemen clutch lining, spring and "0" rings; kit b. replacement pistol and bearing assembly; kit c. replacement piston rod and bearing assembly; and kit d. replacement cylinder assembl) Prices for the kits vary according to the model but eve if all four kits are needed, the cost less than half the price of new unit.