More Clarkson Specialities.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

Steam-impelled Electric-lighting Sets. Forged-steel Road Wheels.

ln our last issue we devoted half a page to a resume of that portion of Mr. Clarkson's.; recent interesting paper entitled " Some recent developments in commercial-motor vehieles "—read before the Institute of Civil Engineers—which dealt with the latest design of the Clarkson steam chassis suitable for employment as a motorbus or a three-ton lorry.

On that occasion we promised, if space permitted, to deal separately with what Mr. Clarkson had to say eoncerniug the developments he has inaugurated in connection with vehicle lighting and with the con struction of road wheels. We are now happy to be able to redeem that promise.

Oil—Acetylene Electric.

The author of the paper, of course, dealt with motor-vehicle-lighting plant of the types which are particularly required for motorbuses. At the present time acetylene and electric plant have entirely ousted the oil lamp for this class of work, and there is undoubtedly to be noticed a distinct strengthening of the claims of those who are exploitingthe electric varieties of installations, and, on the scores of greater cleanliness and better distribution of illumination, the electric dynamo is in many instances replacing the acetylene generator for motorbus work.

Storage-battery and Dynamo-battery Systems.

Of electric plants as at present in use, sonic of them obtain the lighting entirely from storage batteries, whilst in others a small battery is used in combination with a dynamo and an automatic cut-out, which latter switches the dynamo on and off as the speed is above or below what is requisite for excitation. The chief drawback to the employment of batteries alone is, of course, that the illumination is of necessity comparatively feeble. It is only 'possible to carry a battery of limited weight, for obvious reasons.

So far as actual illumination is concerned, the battery-dynamo method gives much better results, but it is more expensive, and to a. certain extent more complicated. Mr. Clarkson, realizing the drawbacks as stated above, of the various available systems of illuminating motorbuses, has designed and installed, with entire satisfaction, a special method of lighting on the omnibuses of the National Steam Omnibus Co. No batteries are new used on these vehicles.

The Clarkson Steam-electric Set.

The generating plant consists of an engine with a pair of single-acting cylinders working on opposite cranks. There is one slide valve for both cylinders, arid this is actuated through a rocking lever and cam on the crankshaft. A pressure of about 70 lb. per sq. in. is found ample to provide abundant illumination for a complete double-deck motorbus both inside and out. The engine and the direct-coupled dynamo run at 950 r.p.m., and the dynamo has an output, of 14 amperes at 12 volts. Metallic-filament lamps are irsed.

100 lb. Saving in Weight.

Mr. Clarkson finds that this equipment is cheaper to install and maintain, and effects a saving of 100 lb. in weight as compared with any battery-dynamo system of which he has knowledge. The effect of fluctuations in boiler pressure which are inevitable in consequence of the variable demands for power, especially when the motorbus is operating in congested traffic, is avoided by the fitting of a reducing valve. This controls the pressure of steam applied to the lighting engine, and maintains a practically constant voltage without the intervention of any mechanical governor, even when the boiler pressure varies between 200 lb. and 350 lb. per sq. in.

With regard to the special developments in metal road-wheel construction for which Mr. Clarkson has been responsible, he had something interesting to say in the paper from which we are at present making extracts.

Hollow' and Cruciform Cast Spokes.

After a few introductory remarks with regard to the two types of cast-steel road wheels which are at the present time finding considerable favour with operating engineers, viz., the wheel with the solid, cast, bifurcated spoke, and the type with the hollow spoke, he offered the criticism that cast wheels possess inherent drawbacks in respect of lack of homogeneity and their method of manufacture.

"Hollow-spoke cast wheels have a better appearance than those with spokes of cruciform section, and they are more easily cleaned than the latter, but in practice they are heavier and they are more expensive to produce. In order to provide for possible variations in thickness and in the quality of the cast metal, as well as for the possible presence of blow-holes, addition has to be made to the weight of the section of all cast-steel wheels."

Forgings Instead of Castings.

By analogy with other practiee in motor-vehicle construction, Mr. Clarkson favours the employment of forged parts in the place of castings, in order to secure greater reliability, reduction of weight, and cleaner appearance.

"In pleasure cars," we proceed to extract from Mr. Clarkson's paper, "there has been no serious attempt to supersede the wooden wheel byone of east metal, but the development has here proceeded directly from the wooden wheel to the forged variety, the latter being formed of two pressed-steel sections welded together by the oxyacetylene process. This type of forged wheel, although coming rapidly into favour with pleasure cars, has not proved equally satisfactory for heavier duties. When reinforced by a steel disc in the centre plane of the wheel, this type has proved serviceable on three-ton machines, but a lighter type of forged wheel has now been produced."

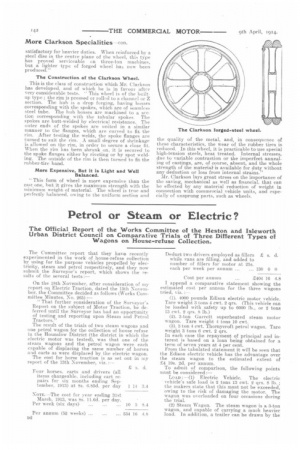

The Construction of the Clarkson Wheel.

This is the class of construction which Mr. Clarkson has developed, and of which he is in favour after very considerable tests, " This wheel is of the builtup type ; the rim is pressed or rolled to a channel or Z section. The hub is a drop forging, having bosses corresponding with the spokes, which are of seamless steel tube. The hub bosses are machined to a section corresponding with the tubular spokes. The spokes are butt-welded by electrical resistance. The outer ends of the spokes are united in a similar manner to the flanges, which are curved to fit the rim. After testing the welds, the spoke flanges are turned to suit. the rim. A small degree of shrinkage is allowed on the rim, in order to secure a close fit. When the rim has been shrunk on, it is secured to the spoke flanges either by riveting or by spot welding. The outside of the rim is then turned to fit the rubber-tire band.

More Expensive, But it is Light and Well Balanced.

"This form of wheel is more expensive than the cast one, hut it gives the maximum strength with the minimum weight of material. The wheel is true and perfectly balanced, owing to the uniform section and the quality of the metal, and, in consequence of these characteristics, the wear of the rubber tires is reduced. In this wheel, it is practicable to-use special high-tension steels, heat treated. Internal stresses, due to variable contraction or the imperfect annealing of castings, are, of course, absent, and the whole strength of the material' is available for duty without any deduction or loss from internal strains." Mr. Clarkson lays great stress on the importance of the saving, mechanical as well as financial, that can be effected by any material reduction of weight in connection with commercial vehicle units, and especially of unsprung parts, such as wheels.