Novel Design of Swash-pi ate Engine

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

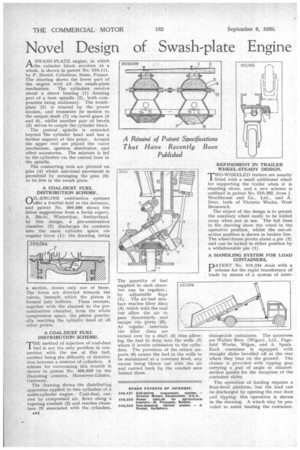

ASWASH-PLATE engine, in which the cylinder block revolves as a whole, is shown in patent No 510,111, by P. Daniel, Colombes, Seine, France. The drawing shows the lower part of the engine with all the swash-plate mechanism. The cylinders revolve about a sleeve bearing (1) forming part of a bent spindle (2), both components being stationary. The swashplate (5) is rotated by the power strokes, and transmits its motion to the output shaft (7) via bevel gears (6 and 8), whilst another pair of bevels (3) serves to couple the cylinder block.

The central spindle is extended beyond 'the cylinder head and has a further support at this point. Around the upper end are placed the valve • mechanism, ignition distributor, and other accessories. The mixture is fed to the cylinders via the central bore in the spindle.

The connecting rods are pivoted on pins (4) whilst universal movement is permitted by arranging the pins (9) to be free in the swash plate.

A COAL-DUST FUEL • DISTRIBUTION SCHEME.

OIL-ENGINE combustion systems Wafer a fruitful field to the inventor, and patent No. 509,086 shows the latest suggestions from a Swiss expert, A. Bilchi, Winterthur, Switzerland. In this design, a pre-combustion chamber (2) discharps its contents into the main cylinder space via angular bores (1); the drawing, being

a section, shows only one of these. The bores are directed towards the valves, beneath which the piston is formed into hollows. These recesses, together with the channel to the precombustion chamber, form the whole compression space, the piston practically reaching the cylinder head at all other points.

A COAL-DUST FUEL DISTRIBUTION SCHEME.

THE method of injection of coal-dust fuel is not the only problem in connection with the use of this fuel, another being the difficulty of distribution between a number of cylinders. A scheme for overcoming this trouble is shown in patent No. 509,659 by the Hanomag concern, Hannover-Linden, Germany.

The drawing shows the distributing apparatus applied to two cylinders of a multi-cylinder engine. Coal-dust, carried by compressed air, flows along a tapering conduit (2) and reaches chambers (3) associated with the cylinders. The quantity of fuel supplied to each chamber can be regulate,: by adjustable flaps (1) . The air-fuel mixture reaches filter discs (4) which hold the coal but allow the air to pass downwards and escape via ports (6). At regular intervals the filter discs are turned over by a shaft (5) thus allowing the fuel to drop into the wells (7) where it awaits admission to the cylinders. The provision of the return airports (6) causes the fuel in the wells to be maintained at a constant level, any excess being blown out with the air and carried back by the conduit seen behind them. REFINEMENT IN TRAILER WHEEL-STEADY DESIGN.

'TWO-WHEELED trailers are usually 1 fitted with a small additional wheel for supporting the trailer when it is standing alone, and a new scheme is outlined in patent No. 510,392, from J. Brockhouse and Co., Ltd., and A. Dear, both of Victoria Works, West Bromwich.

The object of the design is to permit the auxiliary wheel easily to be folded away when not in use. The full lines in the drawing show the wheel in the operative position, whilst the out-ofaction position is shown in broken line. The wheel-frame pivots about a pin (2) and can be locked in either position by a withdrawable pin (1).

A HANDLING SYSTEM FOR LOAD CONTAINERS,

PATENT No. 510,234 deals with a scheme for the rapid transference of loads by means of a system of inter

changeable containers. The patentees are Walker Bros. (Wigan), Ltd., Pagefield Works, Wfgan, and A. Spink. Each container is equipped with straight slides bevelled off at the rear where they bear on the ground. The chassis is provided with tipping gear carrying a pair of angle or channelsection guides for the reception of the container slides.

The operation of loading requires a floor-level platform, but the load can be discharged by opening the rear door and tipping; this operation is shown in the drawing. A winch may be provided to assist hauling the container.