Widening its sco e

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

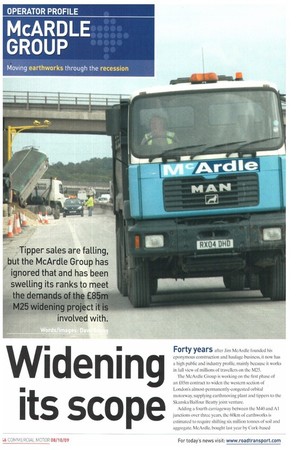

Forty years after Jim McArdle founded his eponymous construction and haulage business, it now has a high public and industry profile, mainly because it works in full view of millions of travellers on the M25.

McArdle Group is working on the first phase of an £85m contract to widen the western section of London's almost-permanently-congested orbital motorway, supplying earthmoving plant and tippers to the Skanska/Ralfour Beatty joint venture.

Adding a fourth carriageway between the M40 and Al junctions over three years, the 60km of earthworks is estimated to require shifting six million tonnes of soil and aggregate. McArdle, bought last year by Cork-based

Mercier Private Equity, is also involved in similar projects on the north-eastern corner of the M25 near the Ml I and the A3 Hindhead tunnel. It previously worked on Heathrow T5 and the southern Ml redevelopment.

Consequently, at a time when tipper sales have been in the doldrums, McArdle has been making additions to its in-house tipper fleet.

The person in charge of purchasing and operations is transport manager Peter Murphy, who starts at 6arn every day and rarely leaves before 7pm. CM got up early to meet him at the company's Colnbrook headquarters, where he shares an office free of pretentious corporate trappings, but is full of files, wall planners and ringing telephones.

Unorthodox career plan

Murphy has been in the business most of his working life. He apprenticed as a mechanic, drove tippers during the days of the legendary Scammell Routeman (an industry favourite), and subsequently became a transport manager. "I've always been around rigid eight-wheel tippers," he says, all the while fielding a series of calls and resolving operational issues. "It wasn't so much a career plan as taking jobs I was offered," he says This latter comment gives a clue to the nature of muckaway (removing material from site) tipping operations — a business built on contact between, mainly, family-run firms; joined at the hip to the construction industry they serve, these businesses are largely resistant to the sort of consolidation and creation of national networks that is transforming other haulage sectors. "The industry is close-knit, we know if people can drive tippers. This is a business built on trust, where managers and drivers know each other," Murphy says. It seems managers are more likely to be hired on the basis of a phone call and a friendly chat with someone who has experience of their ability, rather than by sitting through an interview clutching a logistics degree.

Fluctuating demands

On the contract site on the western stretch of the M25, visited by CM, Murphy and his team must work on and around a live road — one of the busiest in Europe — often in narrow lanes next to fast-moving traffic. Rather than a single excavation. McA rdle has to supply tippers to meet the fluctuating demands of a series of different jobs, many simultaneous, on both sides of the carriageway. The job also involves its lorries from other muckaway and recycling jobs bringing materials on to the site.

There's none of the manoeuvring space associated with green-field locations, and tippers frequently undertake long reverses to dump when building embankments, while excavator operators loading trucks have to beware the bucket does not deposit soil on or, even worse, swing out into the nearside lane.

Professional judgement

Joining the main traffic flow is a nightmare — harassed car drivers already held up by roadworks are in no mood to let a tipper out in front of them — and spilt-second timing and precise professional judgement is vital. Safety is stressed at every operational level. For example, two banksmen are required to supervise reversing, despite the tipper's onboard cameras. Realising that in close, nose-to-tail traffic, car drivers often can't see the amber beacons on cab roofs, McArdle has pioneered the use of flashing warning lights under the tailgate and made it mandatory for its subbies.

The tipper drivers' statutory breaks are co-ordinated with the machine drivers, so everything stops at the same time. Murphy's people-management philosophy is to einphasise team work. He therefore has supervisors capable, enthusiastic and hard-grafting former drivers, such as Gary Stockwell based in a site office, but most of the time they are mobile, liaising with the main client, other sections of the McArdle Group, subcontractors, banksmen, safety officers and the people behind the wheel, to keep thing flowing smoothly.

Every truck on the fleet has a hands-free mobile phone, possibly the most vital element in ensuring rapid responses and redeployments.

With a core fleet of 47 of its own tippers, but using up to 120 lorries a day, McArdle needs subbies, and, once again, the close-knit nature of the tipper community comes into focus. "Loyalty works both ways," says Murphy "There has to be trust, it's very much on personal terms."

When asked why the company doesn't go down the third-party logistics route and do away with an in-house fleet, Murphy says: "It's down to the way the job is supervised. Using your own trucks goes hand-in-hand with civil engineering; it sets a template for subbies, helps credibility and gives clients the confidence we can deliver."

Even when undertaking far-flung contracts, such as in Devon and Dorset, McArdle usually employs a core team of its own out-based drivers to "set the quality standard".

Tkipically undertaken on a dayor load-rate payment, cost-efficient working means reducing the distance between tipping and loading as far as possible, doubleshifting in good times and, to be most effective, working in a mainly local (about 35 miles) patch.

"Haulage is a profit centre in its own right. We run a haulage business in the McArdle Group," Murphy says. Consequently, in addition to this internal market, he undertakes outside work. "We are predominately a muckaway and recycling specialist, including crushing and screening," he says. The slowdown in other sectors of the construction industry means the long-term M25 contract provides welcome revenue stability.

Compliance is key

Murphy sets great store by legal compliance. "We do it by the book. We used to be undercut by cowboys," he says. "About 10 years ago we had problems; adherence to the law could give commercial disadvantage."

Now with VOSA enforcement improving fleets, there is a level playing held, he says. "We dig holes and shift muck," says MeArdle's transport manager, but integrating and co-ordinating fast-changing, complex and potentially dangerous day-to-day operations on a construction site next to a hectic contratlow requires management skills of a high order and Murphy is a man on top of the task. •