Longer Life for Injection Pumps

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

IN recent years it has been determined that filtering media previously used in the fuel systems of oil engines, such as felt, cloth and metal gauze, are not capable of trapping the smaller particles that do the most damage. After making tests on various materials, it has now been generally accepted that treated paper is the most efficient filtering medium for oil fuel.

The degree of wear which develops in an injection pump is proportional to the amount of abrasive material which passes through it. The length of time

required to produce a detrimental amount of wear, therefore, depends upon the amount of abrasive material

suspended in the fuel. The rate at which a filter chokes, however, is only partly caused by trapping the material that does the damage, as the choking layer consists of a form of wax sludge.

Filter life is not, therefore, dependent upon the amount of abrasive material contained in the oil fuel, but on the amount of fuel consumed. Other factors include the area of the filtering medium, the fuel pressure, temperature, and viscosity of the oil fuel.

Art important requirement of the paper-type filter is the large area of paper needed to avoid early choking.

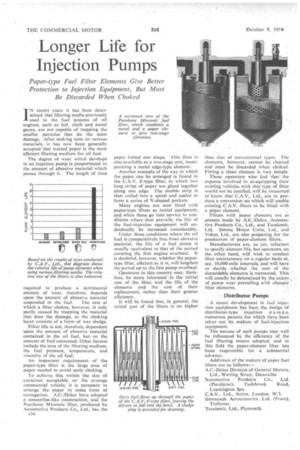

To achieve this within the size of container acceptable on the average commercial vehicle, it is necessary to arrange the paper in some form of corrugation. A.C.-Delco have adopted a concertina-like construction, and the Purolator Micronic filter, produced by Automotive Products Co., Ltd., has the A.34

paper folded star shape. This filter is. also available as a two-stage unit; incorporating a metal edge-type, element.

Another example of the way in which the paper can be arranged is found in the C.A.V. F-type filter, in which two long, strips of paper are glued together along one edge. The double strip. is then coiled into a spiral and sealed to form a series of V-shaped pockets.

Many engines are now fitted with Paper-type filters as initial equipment, and when these go into service in conditions where dust prevails, the life of the fuel-injection equipment will undoubtedly be increased considerably.

Under those conditions where the oil fuel is comparatively free from abrasive material, the life of a fuel . pump is usually equivalent to that of the period covering the first engine overhaul, it is doubtful, however, whetherthe papertype filter, efficient as it is, will lengthen" the period up to the first pump overhaul.

Operators in this country may, therefore, be more interested in the initial • cost of the filter, and the life of the elements and • the cost of their replacement, rather than their greater efficiency.

It will be found that, in general, the initial cost of the filters is no higher

than that of conventional types. The elements, however, cannot be cleaned and must be discarded when choked. Fitting a clean element is very simple.

Those operators who feel that the expense involved in re-equipping their existing vehicles with this' type of filter would not he justified, will be interested td' know that C.A.V, Ltd., are to produce a conversion set which will enable existing C.A.V. filters to be fitted with a paper element.

Filters with paper elements are at present made by A.C.-Delco, Automotive Products Co., Ltd., and Tecalemit, Ltd. Simms Motor Units, Ltd., and Vokes, Ltd., are also preparing for the production of paper-clement filters.

Manufacturers are, as yet, reluctant to specify element life, but operators, on the other hand, will wish to conduct filter maintenance on a regular basis at, say, 10,000-mile intervals, and will have to decide whether the cost of the discardable elements is warranted. This will usually be determined by the extent of pump wear prevailing with cheaper filter elements.

Distributor Pumps

A recent development in fuel injection equipment has been the design Of distributor-type injection pump s, numerous patents for which have been taken out by makers of fuel-injection equipment.

The success of such pumps may well be influenced by the efficiency of the fuel filtering means adopted, and in this field the paper-element filter has been responsible for a substantial advance.

Addretses of the makers of paper fuel filters are as follows:— A.C.-Delco Division of General Motors, Ltd., Watling Street, Dunstable. "Automotive Products Co., Ltd.

(Purolator), Tachbrook Road, Leamington Spa.

C.A.V., Ltd., Acton, London, W.3. Simmonds Aerocessories, Ltd. (Pram), Treforest.

Tecalemit, Ltd., Plymouth.