I t’s all in the

Page 29

Page 30

Page 31

Page 33

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

delivery

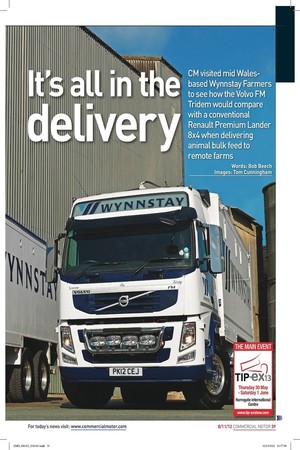

CM visited mid Walesbased Wynnstay Farmers to see how the Volvo FM Tridem would compare with a conventional Renault Premium Lander 8x4 when delivering animal bulk feed to remote farms

Words: Bob Beech Images: Tom Cunningham Big trucks and narrow twisting country roads are rarely a good combination, severely limiting the size of vehicle that can be used. But the new Volvo FM Tridem 8x4 goes some way towards altering this. It combines a conventional front steer-axle, a double-drive bogie and a rear-steer tag-axle, giving both traction and manoeuvrability in a four-axle 32-tonne chassis. The truck has rapidly found favour with operators delivering animal bulk feed to farms. We visited mid Wales-based Wynnstay Farmers to see how it would compare with a conventional Renault Premium Lander 8x4.

Operator opinion

Zac Edwards, logistics manager at Wynnstay Farmers “We operate throughout most of rural Wales, also running into the Midlands and the South West. This involves accessing all types and sizes of farm premises on a regular basis. Many of the smaller farms in mid and north Wales are more suited to a horse and cart than a heavy truck and we have been severely limited with the size of vehicle we can send to these locations. In many instances a short-wheelbase six-wheeler was the largest we could use, and even then it could be a struggle.

“The reduced payload of a 26-tonne rigid, compared with a four-axle 32-tonner, has a direct effect upon the delivery cost per tonne of our products, and like everyone else, we are in a very competitive business and constantly looking for ways to give us an edge. The extra three tonnes payload of a four-axle rigid means that it can deliver up to 30 tonnes of additional product over a working week, which can amount to as much as a £300 saving, which in turn is serious money over the projected 12-year working life of a truck.

“We run a number of conventional eight-wheelers in the fleet, but are limited to where we can send them. We looked at rear-steer 8x2s, but quickly dismissed them, as traction can be an issue in some of the more remote areas in summer, and is a real problem in the winter. The product we deliver is vital for the welfare of livestock. Farmers only carry limited stocks and we have to maintain supply. We really struggle to access some hilly areas when snow falls. Our drivers do a superb job in this respect, but you have to give them the right truck for the job to begin with. “Our interest in the Volvo Tridem came about after we saw a reference to it in the trade press. An operator in a similar line of business had put one into service up in Yorkshire, and as they face pretty much the same operational problems as us, we decided to take a look.

They allowed us to take the truck out and see for ourselves. We were very impressed with the concept, so we decided to take it further.

“We contacted both Thomas Hardie and our local Volvo dealer. Hardie was very keen to do business and responded quickly to our enquiry, and the price quoted was very competitive. We have run Volvos for many years and still have some older FMs in the fleet with over one million kilometres on the clock. But we have tried other makes such as Renault in recent years because of better dealer response and general improvements in their products.

“As a result of our trial we ordered three Tridem FM rigids, with the 11-litre engine rated at 410hp and the I-Shift transmission. This combination has proven itself in the Premium Lander.

“We specified Globetrotter cabs for better aerodynamics and improved driver comfort. The bodywork is by Alibulk/Priden Engineering, which has previous experience with the Tridem chassis. The bodies are a little shorter than on a conventional 8x4, but are slightly higher to compensate.

“The new Volvos are performing very well. The manoeuvrability is superb, and is probably slightly better than a six-wheeler in the tightest of spots. Drivers have to make allowances for the additional tail-swing, but they soon adapt. We specified 9-tonne front axles to avoid front axle overloads with diminishing loads, but it doesn’t seem to be an issue, although care has to be taken with the rearmost steer axle as it is limited to 7.5 tonnes. Fuel consumption is looking good for the FMs, and so far they are recording around 8.5mpg, according to the Dynafleet software, and slightly better via our in-house fuel monitoring.

“We have run Renault eight wheelers for nearly four years. We were initially attracted by the specification and value for money they offer. But the four-year warranty, which came as part of the package, was a big factor too. I wouldn’t hesitate to try them again, especially as we receive superb support from the local dealer.

“Although it is still early days, I see the Tridem set-up as ideal for our application. Renault now offers a similar layout and we will be keen to see it in action.

“But if they continue to perform this well throughout their life, we might well move over completely to Tridems in the future.” n

CM opinion

The unconventional appearance of the FM Tridem 8x4, with its short-wheelbase and three rear axles, make it really stand out. The use of 385/65 super-singles on both steer axles help to give it a balanced look.

The ultra-tight turning circle of this FM comes as something of a surprise. On full lock the vehicle rotates around the mid-point of the two drive axles, but unlike a similar wheelbase 6x4, there is a complete absence of low-speed understeer, as the rear-steer axle pushes the rear end in the opposite direction. Rear tail-swing needs to be taken into account in really tight spots, but a combination of good mirrors and a rear-facing camera should keep drivers out of trouble. The turning circle is more akin to an empty 6x2 rigid with the tag axle raised. Using standard-sized car parking bays as a reference, it will turn within four marked spaces, with room to spare.

The unladen ride is quite firm on rough surfaces. The big tyres and 9-tonne front axle require a bit of imposed weight to work properly, but there is none of the fore and aft pitching associated with shortwheelbase six-wheelers. The combination of double-drive and weight transfer/lift on the tag-axle should ensure good traction, laden and empty. Conventional 8x4s often struggle to get a grip after tipping a load, especially as the wide-spaced front bogie layout favoured by manufacturers takes weight off lightly laden drive-axles on undulating ground.

The Premium Lander obviously needs quite a bit more space to manoeuvre due to its conventional axle layout and longer wheelbase. But the Renault is far from unwieldy. It has a very good lock and first-rate vision, despite the high-mounted cab. The ride is smooth and there is little roll through the bends. It is one of the best handling 8x4s on the market, with light responsive steering and first-rate brakes.

With similar drivelines, save for the Renault hub-reduction axles (which must incur a slight fuel penalty), both trucks have similar performance and share excellent transmissions that require little driver intervention.

So this is not so much a choice between rival makes, more a matter of which axle layout is best for this application. It’s still early days, but the Tridem seems to offer real advantages in this instance.

AXLE LAYOUT

Traditionally, most UK operators have been less adventurous than their European counterparts when it comes to axle layouts on threeand four-axle rigid chassis. It was either single-drive with a lift-axle, or double-drive if traction was an issue.

But things have changed gradually. First rear-steer axles appeared on six-wheelers, with operators quickly appreciating the benefits of improved manoeuvrability and reduced tyre wear. It allowed them to use a three-axle chassis in place of an 18-tonner, thus carrying more payload. Rear-steer axles were then applied to 8x2 rigids, finding favour with milk tanker and brick and block hauliers. Once again, manoeuvrability, reduced running costs and increased payload were the key factors.

The latest developments with Tridem rear bogies – offering the turning circle of a short-wheelbase six-wheeler, combined with double-drive traction and the payload of an eight-wheeler – give real benefits for operators who have to contend with restricted access sites. Small farms are a perfect example of this. In the past animal feed was delivered in bagged form on two-axle rigids, but for many this is not an option. Labour is no longer cheap, so time is a factor for both truck operator and farmer.

Furthermore, few drivers would be prepared to handball 10-plus tonnes on a regular basis.

As a result most farmers now take their feed in bulk form direct into silos. It’s cheaper, results in less waste and suits modern farming methods.

The advantages of increased payload, combined with first-rate manoeuvrability, makes the Tridem setup ideal for this application.

It’s difficult to assess the size of the potential market for this axle layout. We feel there are definite opportunities in a number of sectors (such as fuel oil suppliers), but operators need to have a practical demonstration to be made aware of the benefits.

The downsides are a slightly more complex specification, with rear air suspension and hydraulic steering. The requirement to specify a chassis sub-frame with a tipping body and limited ground clearance under the rearmost anti-roll bar will rule out the concept in more arduous tipper applications.

Manoeuvrability apart, the layout offers first-rate stability when tipping. This is important in this application where cargo remains in the front body compartments when discharging part loads. Unladen weight does not seem to be an issue. Tyre wear should be improved, with less scrub when turning and fewer shunts in tight spots, although there will be a tendency to corner just that bit harder on faster roads.

We expect one or two other manufacturers will enter this sector in the future. The numbers sold will not be that high, but trucks like this have a long service life.

Wynnstay keeps its trucks for more than a decade, and although they are maintained in-house, the relative complexity of any 8x4 means that there is a high volume of potential parts sales revenue for local dealers as the trucks age, far more than any fleet spec tractor unit on a three-year contract.