Twin King-pins Solve "Artic" Problems

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

The device affords several advantages. There is an increasing tendency for operators to buy semi-trailers with kingpins well set back (42 in. from the front) to afford maximum body .length when employed with tractors having rather long wheelbases. These semi-trailers cannot, however, be used with shorter-wheelbase tractors.

The York dual king-pin solves this problem. It deals also with a difficulty experienced in operating articulated outfits on cross-Channel haulage services. For Continental work the king-pin needs to be about 18 in. from the front of the senii-trailer, so that the landing-gear legs clear the rear wheels of tandem-axle tractors, which are frequently used in Europe. This location is generally unsuitable for the United Kingdom, because it is likely to cause the outfit to exceed the

maximum legal length and the weight distribution is upset.

A range of nine locations is offered for the twin king-pins. In four models the pins are 12 in. apart, with the front one 12 in., 18 in., 24 in. or 30 in. from the forward edge of the semi-trailer. An 18-in. spacing is provided in three other examples, the front pin being set back 12 in., 18 in. or 24 in. In the two remaining models the interval is 24 in., with the front pin set back 12 in. or 18 in.

The cost of the gear on a new semitrailer is £64. Conversions cost £87 if the existing king-pin location is similar to one of the two positions in the range selected. Otherwise, there is an extra charge for a pick-up plate designed for the particular conversion.

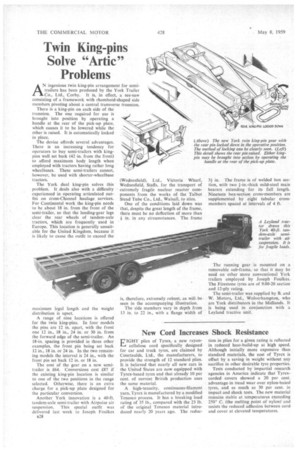

Another York innovation is a 40-ft. tandem-axle semi-trailer with Airpoise air suspension. This special outfit was delivered last week to Joseph Foulkes Et28 (Wednesfield), Ltd., Victoria Wharf, Wednesfield, Staffs, for the transport of extremely fragile nuclear reactor components from the works of the Talbot Stead Tube Co., Ltd., Walsall, to sites.

One of the conditions laid down was that, despite the great length of the frame, there must be no deflection of more than in. in any circumstances. The frame is, therefore, extremely robust, as will be seen in the accompanying illustration. The side members vary in depth from 13 in. to 22 in., with a flange width of

3+ in. The frame is of welded box section, with two 4-in.-thick mild-steel main bearers extending for its full length. Nineteen box-section cross-members are supplemented by eight tubular crossmembers spaced at intervals of 4 ft.

The running gear is mounted on a removable sub-frame, so that it may be used on other more conventional York trailers employed by Joseph Foulkes.. The Firestone tyres are of 9.00-20 section and 12-ply rating.

The semi-trailer was supplied by B. and W. Motors, Ltd., Wolverhampton, who are York distributors in the Midlands. It is being used in conjunction with a Leyland tractive unit.