A HYBRID ENGINE.

Page 76

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Recently Published Patent Specifications.

T"specification, No. 271,442, of Albert A. A. Darche, who hails from Algeria, points out that there are two types of internal-combustion engine, one in which a combustible mixture is introduced into the cylinder, which may be called an " explosion" engine, the other being one where the fuel is introduced progressively into the cylinder, which is described as a " combustion" engine, of which the Diesel is typical. The present invention aims at providing an intermediate type of four-stroke engine, working successively by " explosion" and "combustion." In this engine the total amount of fuel used on full load during each cycle is introduced in two distinctly separate stages. The first fraction of the fuel is introduced during the suction stroke for providing preliminarily an explosive mixture, the remaining fuel being gradually introduced into the burning charge towards the end of the explosion.

A New Method of Attaching Brake Facing.

THE method of attaching brake material to its shoe, described in the specification, No. 264,479, of the Societe Anonyrne Franctuse du Ferodo, of Paris. is a metal plate, bent to the, form of the shoe, the facing being cemented to it.

Holes are made in the material sufficiently large to take the heads of the rivets or screws which hold the metal plate to the shoe. It would appear that the cement is entirely relied upon for holding the facing to the metal. Glue and Bakelite are both mentioned as cements that may be employed.

To Prevent Wheel Wobble.

THE subject of wheel wobble and its cure appears to be

attracting the attention of designers, if we may judge from the devices which have recently been claimed to remedy this fault. In the present case the device emanates from the brain of Frederick Henry Royce and is described in specification No. 287,948.

Attached to the ,front axle is a cylinder;. in the centre of this slides a double piston which is actuated by means of a lever connected by a suitable link to one of the steering arms, so that as the arm moves in either direction it causes the pistons to elide towards one end of the cylinder, thus compressing fluid at one end and causing a vacuum at the other end. By this means fluid is forced out of one end of the cylinder and, passing through a return pipe, enters the other end of the cylinder. The apertures through which the fluid has to pass are contracted so that rapid movement of the piston is arrested, but the normal movement necessary for steering is said not to be impeded.

We should imagine that a very careful adjustment of these apertures is needed, as there are times when a steer

• ng wheel is required to be moved quickly.

A Hydraulic Variable Speed Gear.

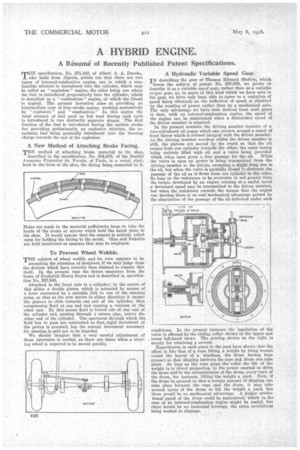

IN describing the gear of Thomas Edward Shelton, which

forms the subject of patent No. 287,659, we prefer to describe it as a variable speed gear, rather than as a variable torque gear, as, in gears of this kind which we have seen in the past, we have only been able to agree to a variation of speed being obtained, as the reduction of speed is obtained by the wasting of power rather than by a mechanical gain. The only advantage we have seen derived from such gears is that, with an internal-combustion engine, the speed of the engine can be maintained when a diminished speed of the driven member is required.

In the present instance the driving member consists of a two-eylindered oil pump which can revolve around a crank of fixed throw which is formed integral with the driven member. As the driving member revolves whilst the driven member is still, the pistons are moved by the crank so that the oil surges from one cylinder towards the other, the outer casing being entirely filled with oil and a valve being provided which when open gives a free passage for the oil. While the valve is open no power is being transmitted from the driving member to the driven, excepting a slight drag due to the oil, but when the valve is partially closed it obstructs the passage of the oil as it flows from one cylinder to the other, So long as the resistance to be overcome is not greater than the torque developed by an engine running at a useful speed a decreased speed may be transmitted to the driven member, but when the resistance exceeds the torque that the engine can develop there is no real mechanical advantage gained by the obstruction of the passage of the oil delivered under such conditions. In the present instance the regulation of the valve is effected by the sliding collar shown in the upper and lower left-hand views. The gearing shown on the right is merely for obtaining a reverse.

Experiments in such gears in the past have shown that the effect is like that of a rope lifting a weight by being wound round the barrel of a windlass, the drum having been greased so that slipping between the rope and drum can take place. So long as the rope grips the .roller the lift of the weight is in direct proportion to the power exerted to drive the drum and to the circumference of the drum, every turn of the drum, for instance, lifting the weight a yard.. Now, if , the drum be greased so that a certain amount of slipping can take place between the rope .and the drum, it may take several turns of the drum to lift the weight a yard, but there would be no mechanical advantage. A higher revolutional speed of the drum could be maintained. which in the • case of an internal-Combustion engine might be useful, but there would be no increased leverage, the extra revolutions being wasted in slippage.'