Lamps Alight.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

Light your lamps at 6.27 in London, 7.7. in Edinburgh, 6.31 in Newcastle, 6.38 in Liverpool, 6.33 in Birmingham, 6.37 in'Bristol, and 7.20 in. Dublin.

An Extraordinary Big-end Failure.

[1720] " C. S.W," (Norbiton)' writes :—" With reference to your letter No. 1715, by MM.,' of West Bromwich, in the issue of THE COMMERCIAL MOTOR of the 15th February, concerning an unusual failure of a bigend bearing, this appeals to me rather in the nature of an object lesson on the failing of phosphor bronze as a suitable material for the purpose 'in question.

" It is possible that the reasons for this failure were quite normal ones. For example, notwithstanding the fact that the hollow crankshaft may be full of oil, it is always possible' that the particular duct which fed the bearing which failed was at the time blocked by some foreign matter ; alternatively, the metal employed may have been somewhat 'short.' The latter reason would explain the peculiar feature of crumbling of the bearing which was noted by H.M.' On the other hand, if anti-friction metal had been used for this bearing instead of phosphor bronze the resultant contingent damage, in which I include the cylinder head breakage and the scoring of the crankshaft, -4;ould not have occurred, neither would the shaft itself have become twisted, because it is a feature of white metal that as soon as it reaches a certain heat, the metal runs, thereby saving any other damage than the failure of the bearing. In this regard, I should like to state that I have had a fair amount of experience. There is not the slightest doubt that anti-friction metal for bearings is a great boon to motor-vehicle manufacturers, whether of petrol lorries or steamers.'

For Crankshaft Repairs.

The sender of the following communication has been awarded the tOs. prize this wee/c.

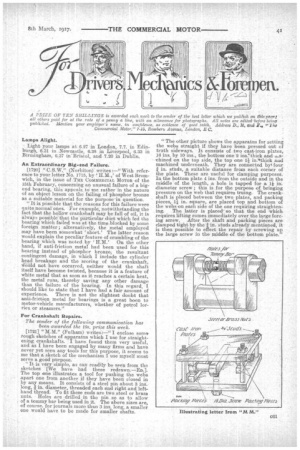

[1721] "MM." (Fulham) writes :—" I enclose sorno rough sketches of apparatus which I use for straightening crankshafts. I have found them very useful, and as I have been engaged by many firms and have never yet seen any tools for this purpose, it seems to me that a sketch of the mechanism I use myself must serve a good purpose. It is very simple, as can readily be seen from the sketches [We have had these redrawn.—En.]. The top one illustrates a tool for pushing the webs apart one from another if they have been closed in by any means. It consists of a steel pin about 3 ins. long, I in. diameter, threaded each end right and lefthand thread. To fit those ends are two steel or brass nuts. Holes are drilled in the pin so as to allow of a toramy bar being used in it. The above sizes are, of course, for journals more than 3 ins, long, a smaller one would have to be made for smaller shafts. "The other picture shows the apparatus for setting the webs straight if they have been pressed out of truth sideways. It consists of two east-iron plates, 16 ins. by 10 ins., the bottom one 2 ins...thick and ina,chined on the top side, the top one 1 in.lothick and machined underneath. They are connected byi four in. studs, a suitable distance from each corner of the plate. These are useful for clamping purposes. In the bottom plate 4 ins, from the outside and in the middle of the length, a. hole is tapped for a 1-if in. diameter screw ; this is for the purpose of bringing pressure on the web that requires truing. The crankshaft is placed between the two plates, and packing pieces, 1,1 in. square, are placed top and bottom of the webs on each side of the one requiring straightening. The latter is placed" so that the end which requires lifting comes immediately over the large forcing screw. After the shaft and packing pieces are clamped tight by the in. studs already mentioned, it is then possible to effect the repair by screwing up the large screw in the middle of the bottom plate."