Send the sticky

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

Pbs out • • • by Bill Brock

CAN cars in a mixed fleet be maintained adequately, or is it better to contract the work out to local garages? This is the question I put to Jim Boyce, transport consultant for the Vine Products group based at Kingston upon Thames.

Jim's reply was based on the economics of the situation. Once a company commits itself by providing suitable facilities to service' one section of its fleet, the major objections have been overcome and there is little to gain in farming out the maintenance of another section.

Big factor

Jim has overall responsibility for a transport fleet of 250 cars, 20 vans up to 30cwt and 70 commercial vehicles including tankers operating at up to 32 tons, so a positive servicing policy is needed if they are all to be kept in reliable working order.

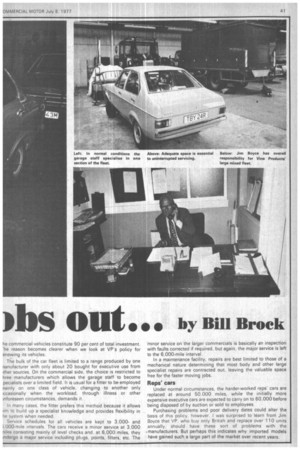

Costs can be broken down simply into three broad divisions: The premises with its associated expenses of lighting, heating and equipment, replacement parts and their storage and, most important, the labour force. The garage premises is a big factor contributing to the succes or failure of any service facility. Adequate space allows for a quic turnround. Not having to shunt vehicles about to fit them in is vitE if time is not to be wasted. And, perhaps more relevant to th result, it allows the allocation of work to flow uninterrupted.

The workshops at Kingston are about a quarter-mile from th main factory. As well as Vine Products, Hanworth Food Product and Wooleys Duval Beaufoy's, the other two companies witI vehicles in the fleet, have expanded during recent years and so, c course, has their requirement. The existing garage is now a bi cramped for the volume of work it has to handle, but a nev workshop is to be built near the main factory next year.

A fleet this size requires a substantial number of replacemen parts on hand. Even restricting the majority to fast moving items over £15,000 worth is needed as a minimum. In times of higl inflation and after short supply the initial capital outlay pays of time after time.

• Although cars form the biggest part of the fleet, spare parts fc he commercial vehicles constitute 90 per cent of total investment. he reason becomes clearer when we look at VP's policy for enewing its vehicles.

The bulk of the car fleet is limited to a range produced by one nanufacturer with only about 20 bought for executive use from rther sources. On the commercial side, the choice is restricted to hree manufacturers which allows the garage staff to become pecialists over a limited field. It is usual for a fitter to be employed nainly on one class of vehicle, changing to another only iccasionally when the workload, through illness or other inforeseen circumstances, demands it

In many cases, the fitter prefers. this method because it allows i rn to build up a specialist knowledge and provides flexibility in he system when needed,

Service schedules for all vehicles are kept to 3,000and i,000-mile intervals. The cars receive a minor service at 3,000 niles consisting mainly of level checks and, at 6,000 miles, they indergo a major service including plugs, points, filters, etc. The minor service on the larger commercials is basically an inspection with faults corrected if required, but again, the major service is left to the 6,000-mile interval.

In a maintenance facility, repairs are best limited to those of a mechanical nature determining that most body and other large specialist repairs are contracted out, leaving the valuable space free for the faster moving jobs.

Reps' cars

Under normal circumstances, the harder-worked reps' cars are replaced at around 50,000 miles, while the initially more expensive executive cars are expected to carry on to 60,000 before being disposed of by auction or sold to employees. Purchasing problems and poor delivery dates could alter the basis of this policy, however. I was surprised to learn from Jim Boyce that VP, who buy only British and replace over 110 units annually, Should have these sort of problems with the manufacturers. But perhaps this indicates why imported models have gained such a large part of the market over recent years.