• HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

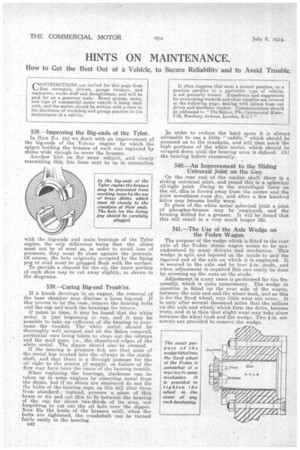

538.--Improving the Big-ends of the Tylor.

In Hint No. 516 we dealt with an improvement of the big-ends of the Vulcan engine by which the spigot holding the brasses of each was replaced by shims wide enough to cover the brasses.

Another hint on the same subject, and closely resembling this, has been sent to us in connection with the big-ends and main bearings of the Tyler engine, the only difference being that the shims must not be of steel as, in order to avoid loss of pressure, they must fit close against the journals. Of course, the hole originally occupied by the fixing peg or stud must be plugged flush with the surface. To provide a channel for the oil, the inner portion of each shim may be cut away slightly, as shown in the diagrams.

539.—Curing Big-end Troub7es.

If a knock develops in an engine, the removal of the base chamber may disclose a loose big-end. If this proves to be the case, remove the bearing bolts and the cap and mark the bearings for return.

If taken in time, it may be found that the white metal is just beginning to run, and it may be possible to take up sufficient of the bearing to overcome the trouble. The -white metal should be thoroughly well scraped and all the flakes removed, particular care being taken to clean out the oilways and the mud gaps, i.e., the chamfered edges of the white metal. The dipper should also' be cleaned.

If the bearing is pressure fed, see that none of the metal has worked into the oilways in the crankshaft, and that there is a through passage for the oil right to the source of supply, as failure of the flow may have been the cause of the bearing trouble.

When 'replacing the bearings„ slackness can, be taken up in some engines by removing metal from the shims, but if no shims are employed do not file the bats of the bearing caps, as this will alter them from standard ; instead, procure a piece of thin brass or tin and cut this to fit between the bearing of the cap for about two-thirds of its area, not forgetting to cut out the oil hole over the dipper. Now file the butts of the brasses until, when the bolts are tightened, the crankshaft can be turned fairly y easily n the bearing. B42

In order to reduce the hard spots it is alway advisable to use a little "caddie," which should be smeared on to the crankpin, and will then mark the high portions of thewhite metal, which should be scraped down until the bearing area is defined. Oil the bearing before reassembly.

540.—An Improvement to the Sliding Universal Joint on the Guy.

On the rear end of the cardan shaft there is a sliding universal joint, and round this is a spherical oil-tight joint. Owing to the centrifugal force on the oil, this is forced away from the centre and the joint sometimes runs dry, and after a few hundred miles may become badly worn.

In place of the white metal spherical joint a joint of phosphor-bronze may be employed, and the housing drilled for a greaser. It will be found that this will result in a very much longer life.

541.—The Use of the Axle Wedge on the Foden Wagon,

The purpose of the wedge which is fitted to the rear axle of the Foden steam wagon seems to be misunderstood by many drivers and mechanics. 'This wedge is split and tapered on the inside to suit the tapered end of the axle on which it is employed. It is secured to the axle end by four 1-in. studs, and when adjustment is required this cast easily be done by screwing rap the nuts on the studs.

Adjustment in many cases is performed far too frequently, which is quite unnecessary. The wedge in ()nestle!' is fitted on the near side of the wagon, between the axle end and the wheel bush, and as this is for the fixed wheel, very little wear can occur. It is only' after several thousand miles that the splines on the axle and wheel,' which form the drive, become worn, and it is then that slight wear may take place between the wheel bush and the wedge. Two f-in. setscrews are provided to remove the wedge.