LUMICATINC CHASSIS PARTS.

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

The Relative Advantages of Grease and Oil for Minor Bearings. How Periodic Attention Reduces Rattle and Wear.

ADEQUATE lubrication of all working parts cannot too often be insisted upon, because attention in this direction is always well repaid by the prolonged life of the vehicle, freedom from mechanical breakdowns and reduced running costs generally. In the ease of important components, such as the engine, the gearbox and the back axle, sufficient attention is usually given to ensure smooth running, because a dry pair of gears will at once give warning of their cofidition, and the driver knows very well that many important bearings, such as these which support the crankshaft, will cause an immense amount • of damage if they are under-oiled.

There are, however, numbers of minor bearings in every chassis which are likely to be neglected— first, because they will run dry for a considerable period witliout giving any warning beyond, perhaps, an occasional squeak ; and, secondly, because they are often inaccessible, so that it is .a tedious task to go over them one by one. The lubrication of these parts is nevertheless essential, particularly in view of the fact that they are very often exposed to the action of damp and grit, which, Unless a good film of lubricant is present, will work in between the bearing surfaces, leading to rust and partial seizure in some cases or undue wear in others.

The ease with which a lorry can be handled also depends upon the attention given to a number of small bearings, particularly those found in the steering and braking gears. Many drivers fail to realize that if the brake rods and levers are neglected the friction at these points may easily double the effort required at' the brake pedal to 'pull the lorry up in n given distance. Then, again, stiff steering is very often due to dry pivots in the link gear, or .inaiTequately lubricated steering heads. It should be the aim of every manufacturer to i locate the necessary lubricators n accessible positions, to provide 's simple chart showing the parts requiring lubrication and the frequency with which they must be i—Wenished, and to fit lubricators which can easily be operated.

Not so long ago screw-down grease-cups were almost universally employed, the procedure being to fill the cup, screw it on, and give it a turn or two occasionally until all the grease was exhausted. These cups have several disadvantages, among which may be mentioned their liability to become loose and fall off when subjected to vibration, the facility with which the threads can be crossed and stripped and the leakage of grease past the threads, which makes it impossible to insert the lubricant under very great pressure. There can be no question that the grease-gun system—which is practically universal on pleasure cars, and is rapidly gaining favour for commercial vehicles—represents a great advance on the screwdown greaser. With this system nipples are provided with drilled .holes through which the grease can pass, sealed by spring-loaded balls, which prevent the ingress of dirt or moisture. Various methods are used for attaching the grease-gun to the nipple, such as screwed connections, bayonet catches, etc. With many grease-guns the lubricant is supplied under very high pressure, and this alone is an important advantage, because it ensures that old lubricant and dirt are forced right out of the bearing in front of the ingoing grease.

Many designers regard grease as an unsatisfactory lubricant, because they do not believe that it will -permeate all parts of the bearing with the effectiveness of oil. 'There was a great deal to be said for this point of view before the advent of the grease-gun, but with. this instrument such a high pressure can be obtained that there is no doubt about the grease being forced to allparts of the bearing, provided that suitable hales and grooves are cut to distribute it.

However, in winter many kinds of grea„se become very stiff and tend to congeal, and in these circumstances oil still has an advantage. The simplest form of oiler consists of a cup sealed by a hinged introduced

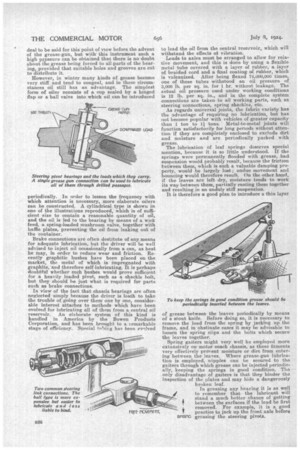

Steering or a ball valve into which oil can be

periodically. In order to lessen the frequency with which attention is necessary, more elaborate oilers can be constructed. A cylindrical type is shown in one of the illustrations reproduced, which is of sufficient size to contain a reasonable quantity of oil, and the oil is led to the bearing by means of a wick feed, a spring-loaded mushroom valve, together with baffle plates, preventing the oil from leaking out of the container.

Brake connections are often destitute of any means for adequate lubrication, but the driver will be well advised to inject oil occasionally from a can, as best he may, in order to reduce wear and friction. Recently graphitic bushes have been placed on the market, the metal of which is impregnated with graphite, and therefore self-lubricating. It is perhaps doubtful whether such bushes would prove sufficient for a heavily loaded pivot, such as a shackle bolt, but they should he just what is required for parts such as brake connections.

In view of the fact that chassis bearings are often neglected simply because the driver is loath to take the trouble of going over them' one by one, considerable interest attaches to methods which have been evolved for lubricating all of them from a central oil reservoir. An elaborate system of this kind is handled in America by the Bowen Products Corporation,. and has been brought to a iemarkable stage of efficiency. Special telling has been evelved to lead the oil from the central reservoir, which will withstand the effects of vibration.

Leads to axles must be arranged to allow for relative movement, and this is done by using a flexible metal tube covered with a layer of rubber, a layer of braided cord and a final coating of rubber, which is vulcanized. After being flexed 74,400,000 times, one of these tubes withstood an oil pressure of 3,000 lb. per sq. in. for 1 hr. without leakage. The ectual oil pressure used under working conditions is 12 lb. per sq. in., and in the complete system connections are taken to all working parts, such as steering connections, spying shackles, etc. As regards universal joints, the fabric variety has the advantage of requiring no lubrication, but has not become popular with vehicles of greater capacity than I ton to lei tons. Metal-to-metal joints will function satisfactorily for long periods without attention if they are completely enclosed to exclude dirt and moisture and are periodically packed with grease.

The lubrication of leaf springs deserves special mention, because it is so little understood. If the springs were permanently flooded with grease, bad suspension would probably result, because the friction between them, which is such a valuable damping property, would be largely bet; undue movement and bouncing would therefore result. On the other hand, if the leaves are left dry, moisture tends to work its way between them, partially rusting them together and resulting in an unduly stiff suspension.

It is therefore a good plan to introduce a thin layer of grease between the leaves periodically by means of a stout knife. Before doing so, it is necessary to remove, the load from the spring by jacking up the frame, and in obstinate cases it may be advisable to loosen the spring clips and the bolts which secure the leaves together.

Spring gaiters might very well be employed more extensively on motorcoach chassis, as these fitments very effectively prevent moisture or dirt from entering between the leaves. Where grease-gun lubrication is employed, nipples can be secured to the gaiters through which grease can be injected .periodic, ally, keeping the springs in good condition. The only disadvantage of gaiters is that they hinder the inspection of the elates and may hide a dangerously to remember that the lubricant will between the surfaces if the load be first broken leaf. stand a much better chance of getting In greasing any bearing it is as well removed. For example, it is a good practice to jack up the front axle before BirlDiriG greasing the steering pivots.