fi-oin Drivers &Mechanics

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the hest communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send us an account of any sPecial incident of your work or experience. If suitable, we will edit your notes, supply a sketch when required, and pay you for everyllzing published. Mention your employer's name, in confidence, as evidence of good faith. Address to Ms Editor, THE COMMERCIAL MOTOR, Eosebery Avenue, London, E.C.

Light Up Your Lamps At

5.8 on Thursday ;. 5.0. on Friday ; 5.10 on Saturday • 5.12 on Monday ; 5.14 on Tuesday ; 5.15 on Wednesday.

C.M.0 A. Scheme of Interest to Drivers.

On page 419 will be found full particulars of a new scheme whereby drivers may enrol themselves in a special section of the C.M.U.A.

Repairing Low-tension Ignition Plug Casings.

[1414] " (Lla,ndaff) writes:--" I was re cently faced with the proposition of a repair to four low-tension plug casings. These had done good service, but the driver complained that the hammers would insist on sticking, thus causing the engine to misfire. On taking the parts adrift, I found that the hammers had not only badly worn down in the countersunk part of the casing, but also were very loose in the bore. Thus the trouble was located at once.

"Rather than discard the casings, and also to save myself the trouble of making new hammers, I proceeded to effect a repair as shown in the accompanying sketch [We have had this redrawn.—En.]. "I put the casing in a table vice on to the drilling machine, and, with a in. diameter twist drill, drilled out the boss' the hole was then tapped out diameter, 20 threads. Four pieces of cast iron, of a suitable length, were then faced, turned, screwed and fitted into the hammer housing. The next operation was to put a.-Iin. diameter twist drill down the centre of the four castings to accommodate the stems of the plug-hanim ers.

"The outer face was then countersunk, as shown in the sketch, and to make the mitring good for the pur pose I procured a piece of in. round tool steel, centred it up, and skimmed it down to in. diameter.

For a length of 212 ins, along one end I turned it to in• diameter, and then set the slide-rest -to the mitre required for the correct taper.

"I made the cutting edges with a file and then hardened the tool. It was then fixed to the drilling machine, and, with the in. diameter stem to act as a pilot, I was enabled to make the countersink to suit my purpose, the in. diameter acting as a dead-true guide."

Driving Mirrors for Steam Wagons.

The sender of the following communication has been awarded the Ws. prize this week.

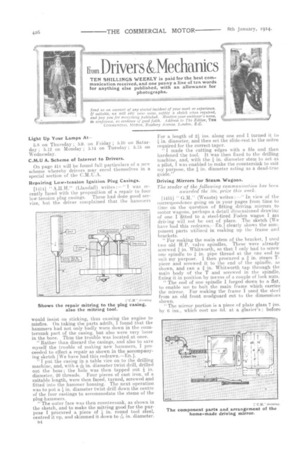

11415] " G.M." (Weaste) writes :—" In view of the correspondence going on in your pages from time to time on the question of fitting driving mirrors to motor wagons, perhaps a detail dimensioned drawing of one I fitted to a steel-tired Foden wagon I am driving will not be out of place. The sketch [We have had this redrawn.En.] clearly shows the component parts utilized in making up the frame and. brackets.

" For making the main stem of the bracket, I used two old H.P. valve spindles. These were already screwed "a in. Whitworth, so that I only had to screw one spindle to in. pipe thread at the one end to suit my purpose. I then procured a 1. in. steam Tpiece and screwed it to the end of the spindle, as shown, and ran a in. Whitworth tap through the main body of the T and screwed in the spindle, fixing it in position by means of a couple of lock nuts.

"The end of one spindle I forged down to a flat, to enable me to bolt the main frame which carries the mirror. For making the frame I used the steel from an old front mudguard cut to the dimensions shown.

"The mirror portion is a piece of plate glass 7 ins. by 6 ins., which cost me Srl. at a glazier's before

fixing it into the frame I placed a piece of rubber insertion all round each edge to absorb vibration.

" To fit the mirror in place on the wagon I bored a f in. hole in a. suitable position in the outside of the rail of the cab roof, on the offside of the wagon. l then fixed the shorter spindle, bent to right angles as shown, to the rail by means of two in. back nuts. The Tpiece permits of the mirror's being adjusted as required.

The one I made has been in use for nearly four months and I find it very satisfactory, and, in fact, I .should not care to he without it."

Nutcracker Lapping Tool.

[14161 " H.B.S." (Sandbach) writes : I recently

had occasion to lap some crankshaft bearings, and, seeing that I file the D. and M.' pages week by week, looked through same to see if I had anything in my collection bearing on the subject. I was not disappointed, and found a letter (No. 1315) published in your issue dateptl 4th September, 1053, which described a method of utilizing strips of fine emery cloth for the purpose. I think, however, with the scheme which I eventually adopted, that I have

scored a march on H.S.' A sketch is enclosed [We have had this redrawn.—Eui showing the arrangement.

" I procured a piece of wood 2 ft. ins, in length the section being 2 ins. by 4 ins., and for forming the hinge I obtained a piece of leather 6 ins. by 2 ins. I had the wood drilled out 2 ins, in diameter one end, which was the diameter of the crank jcurnals. The piece was then sawn down the centre, throughout its length. The two halves were shaped out as shown in the sketch, and I attached the leather to form the hinge ; this rig enabled me to apply even pressure to the bearings. I used the grade of emery cloth recom mended by i.e., F.F., together with machine oil.

"My labourer turned the crank slowly whilst I kept up the pressure on the wood, and the crank journals, when finished, could hardly be distinguished from those which had been ground in a machine."

Mild-steel Bushes as Expanding Chucks.

E1417] " ALMA " (Sandba,eh) writes :—" In the machining of small motor parts, it sometimes happens that the chucks available do not satisfactorily grip the job, owing to the small diameter of the work piece in hand. This is especially true of the self-centring chucks, and also of the independent and combination types.

"The purchasing of new chucks to accommodate the machining of small, odd parts, would of course often involve an outlay which would not pay for the job to be effected. To overcome this, I have made one or two small split bushes of the form shown in the sketch rWe have had this redrawn.---Fe.1 They are made out of mild-steel, and, I must say, they prove entirely satisfactory in use.

"The first one I constructed was to grip some work of in. outside diameter ; the hush was bored out l in.

to allow for contraction, and one saw-cut was put right through one Gide of the bush, and the remaining cuts were made not quite through, as shown in the sketch. The three cuts were of course equally spaced around the circumference.

"I was so pleased with the job that I set to work to make a few extra bushes to accommodate work of various diameters ; the sizes of the bores, commencing from in. diameter, decreased at the rate of h in. respectively."

A Week's Work on a Commercat: [1418] " R.E." (Southse.a) writes :—" I have read with interest many accounts in the CM.' of One day's work,' also records of journeys by steam wagons, etc. Herewith I send you an account of a week's work with a five-ton Commercar which I am driving, thinking perhaps it may prove of interest to other of my fellow readers. " I may say that the details given show quite an average week's work. They are as follow : Monday, load up with barrels and bottle of beer for Tidworth Camp, Salisbury Plain, return home, to Southsea, with empties and reload same night ready for next day ; Tuesday, journey to Bulford Camp, Salisbury Plain, journey home with empties and again load up overnight ; Wednesday, journey to Brighton Pier and barracks, returning with a big collection of barrels ; the journeys for Thursday and Friday are the. same as those undertaken on Monday and Tuesday ; Saturday is shed day, when the machine is cleaned down and any necessary adjustments are effected. The mileage for the five days' running totals up to about 52.5 average, each load being anything up to five tons on the outward journey. It is generally about three tons 10 cwt. on the homeward run. "The. roads of late have been very heavy, one stretch of 11 miles taking 14 hours to cover. This distance, when the roads are dry, usually takes me about an hour. "On occasion I have worked as much as 17 hours a day on this vehicle, snaking full load deliveries at six different places of call. I think this constitutes a record for a five-ton machine."