1N Plenty of operators want a powerful engine in their

Page 70

Page 71

Page 72

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

tractive unit — but not everyone needs a big cab to go on top of it. Over recent years a few switched-on truck manufacturers have noticed this, and are now offering the same engine and driveline with a choice of cabs. Volvo, for instance, offers its 10-litre 229kW (313hp) TD102F engine under the full height-cab F10 tractor, or the lower FL10 (CM 27 October).

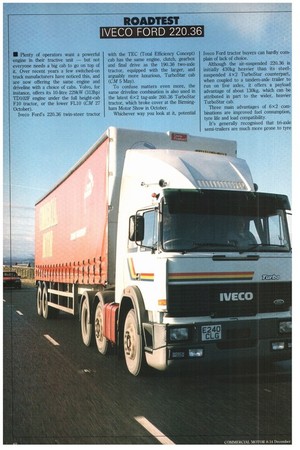

Iveco Ford's 220.36 twin-steer tractor

with the TEC (Total Efficiency Concept) cab has the same engine, clutch, gearbox and final drive as the 190.36 two-axle tractor, equipped with the larger, and arguably more luxurious, TurboStar cab (CM 5 May).

To confuse matters even more, the same driveline combination is also used in the latest 6x2 tag-axle 260.36 TurboStar tractor, which broke cover at the Birmingham Motor Show in October.

Whichever way you look at it, potential lveco Ford tractor buyers can hardly complain of lack of choice.

Although the air-suspended 220.36 is initially 430kg heavier than its steelsuspended 4 x2 TurboStar counterpart, when coupled to a tandem-axle trailer to run on five axles, it offers a payload advantage of about 130kg, which can be attributed in part to the wider, heavier TurboStar cab.

Three main advantages of 6x2 combinations are improved fuel consumption, tyre life and load compatibility.

It's generally recognised that tri-axle semi-trailers are much more prone to tyre scrub than tandem-axled semi-trailers. This not only contributes to greater tyre wear but also increases rolling resistance to the detriment of fuel consumption, particularly on twistier roads. In our experience overall fuel consumption can be expected to be about 1.5% better with a 6x2+2 combination.

Our test results with the 220.36 certainly reflected this over most sections of our route. Only the first of the three days' driving produced adverse figures, and that was due to fog and exceptionally heavy, slow moving traffic on the northbound M6 motorway.

Compared with other tractive units, the twin-steered 220.36 fitted with aluminium wheels has quite a competitive unladen weight of 7.34 tonnes against the similarly shod Leyland Oaf FTS 95.380 at 7.95 tonnes; but it is heavier than the Scania R113 it 7.11 tonnes and the 6.98-tonne Leyland Daf 2035 Roadtrain.

The aforementioned tag-axled Iveco $0.36 TurboStar is quite a bit heavier at 3.030 tonnes, even after allowance has )een made for the 184kg weight penalty its steel wheels.

Rated at 265kW (360hp), the 220.36 CEC tractor's turbocharged and charge:ooled 13.798-litre engine develops its naximum power at just 1,800rpm, with an mpressive 1,766Nm (1,3031bft) of torque woduced at only 1,000rpm. Coupled to a direct-top ZF 16-speed synchromesh gearbox it need only tick over at a sedate 1,550rpm to maintain a steady 96km/h on the motorway. The most economical engine speed is indicated by a solid green segment on the tachometer between 1,100 and 1,400rpm.

With the optional ZF 16S 190 Ecosplit gearbox fitted, as opposed to the constant-mesh 13-speed 116213 Fuller (saving £720) engine speed can easily be held in this narrow 300rpm band for most of the time. Its rear-mounted rangechange provides high and low range ratios on the primary four-speed geartrain, and a front mounted splitter unit doubles the ratios again, to 16. The side-by-side double-H gate is separated by a detent.

Movement up or down the box, through the range change, creates few problems while running on level ground, although gearchanges can't be rushed if they are to be made cleanly. When changing down on steep climbs the extra delay incurred passing through the detent often makes it necessary to skip the next lowest gear.

On earlier models the propshaft was the weak link in the drivetrain. TEC tractive units have adopted a German design originally developed for on-site vehicles using larger-diameter components to increase torsional resistance.

The change from hub-reduction axles to the 13-tonne Rockwell single-reduction axle also simplifies maintenance. Air suspension is used for both rear axles: whenever traction becomes doubtful a dump valve, operated by a button within the cab, can be used to transfer weight on to the drive axle to back up the cross-axle cliff-lock.

In recent tests of 6x2 tractive units we have become used to losing traction, if only momentarily, following a gearchange on the steepest gradients over the sometimes poorly surfaced A68 between Rochester and Nevilles Cross. To avoid this situation, and to obtain the best hillclimb times, it is often better to change down early and keep the engine speed high, so making use of the power rather than relying on the engine's torque.

Unlike the air dump on the Leyland Daf FTG 95.310 twin-steer tested recently (CM 6 October), that of the 220.36 can at least be operated while the truck is on the move.

• PERFORMANCE

On timed hill climbs the 220.36 performed relatively well on all except for Blackhill, and we can find no logical explanation for this, as the vehicle appeared to make the climb in fine style.

Overnight frost and fog were slow tc clear, making track testing difficult. Accel. eration from rest to 801mM is among thE quickest we have recorded in this powei sector, and that performance was re flected in our overall journey times. Or the track, as on the road, it was neces sary to use every gear in sequence. Whei moving away on level ground it was suffi cient to select fourth, followed by eightl and then 10th before resorting to splittiR the gears in order.

Full lever movements tend towards th, slow side, but split changes can be ex ecuted quickly and smoothly, so it is ofte possible to gain an extra gear with littl loss of road speed, even on the steepeo gradients.

Slippery surface conditions restricte our attempts to steeper test hill starts: was necessary to use the diff-lock, whic has to be engaged while the vehicle stationery. On the steep and slipper approach to the hairpin bend at Shotle Bridge, it would have been more useful it could have been engaged on the MOVI Once stopped under such conditions becomes even more difficult to rega enough traction to move away and 1,1 only managed to do so by dumping the o on the second steered axle.

During brake tests all wheels we made to lock under maximum pedal a plication but the vehicle pulled up de: straight. The exhaust brake proved par cularly useful when used with tl appropriate gear on long downhill incline: The clutch pedal requires just 20kg effort to depress it fully to the floor so is not tiring to operate under repeat operation in town or in hilly areas. The three axles on the tractive unit give a more level ride than can be achieved with two, with less pitching moment and less roll. Air suspension adds to the ride quality and improves load equalisation between the axles. Ride height on the 220.36 can also be adjusted to suit different trailer coupling heights, using an external control mounted at the rear of the drive axle.

Roof spoiler and under-bumper air dams are claimed to improve the vehicle's fuel consumption by up to 8%, and the 220.36's overall fuel consumption of 38.59 litres/100km (7.32mpg) is among the best we have recorded in this power class.

• CAB COMFORT

The basic TEC cab has been in service kma good number of years, but there are lot thought to be any immediate plans for ts replacement. Five-point suspension Kids further to the quality of ride provided w the chassis suspension and helps to nsulate the interior from road noise. In

sulation under the floor pan gives extra protection from engine and gearbox noise.

Gas struts support the first grille, giving access to items like the oil filter, dipstick, radiator and clutch and windscreen-washer reservoirs. It must also be raised clear of the bumper when the cab's tilt system is used. A doubleaction hydraulic hand pump lifts the cab effortlessly through 60%: a transmission interlock and engine cutout prevent the engine from being started when the cab is raised.

Entry to the cab is made simple and safe by the provision of two conveniently placed steps and gab handles on either side of the doorway.

The driver's seat automatically compensates for body weight and there are manual adjustments for reach and rake. The angle of the steering column an also be adjusted through a 100 arc.

A fiat fascia houses the instrument binnacle containing the tachograph and tachometer, in the most prominent positions, alongside gauges for fuel, oil and air pressures and engine temperature.

A single switch activates the warning lamps covering a wide range of functions A door pouch and a central console between the seats offer storage space for clipboard and paperwork. Hand controls for the park brake, gearchange, dump valve and diff-lock are centrally mounted within easy reach.

Heater and ventilation controls could hardly be simpler to operate, although as one reader recently pointed out lack of illumination makes it difficult to see which lever to move in the dark. Air vents are plentiful and, even at sub-zero temperatures, cleared the windscreen quickly after starting up.

All-round visibility is good and enhanced by the large heated mirrors which remain acceptably clean on the move.

• SUMMARY

Overall performance once again shows that there are advantages operating 6x2 tractive units. Operators will also be mindful of the service life and residual value of existing triaxle trailers and, in this instance, the difference of about 22,360 in the list prices for the 190.36 and the 220.36.

The 220.36 falls within the most popular power band for operation at 38 tonnes and the combination of high power and torque at low revs makes it an easy vehicle to drive economically while sustaining a high average speed.

The 16-speed ZF gearbox lingers between full gear movements, taking longer to complete a change than the cheaper Fuller alternative, but split gears are very quick to engage.

The slightly-less-than-full-width dimensions of the TEC cab go almost unnoticed. When a trailer and equipment is added to the equation the 220.36 offers slightly more payload than the 190.36 4x2 and is competitive with other 6x2 models.

0 by Bill Brock