Distrust the Man Who Says

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

"I Pulled Up

in My Own Length"

Many Fallacious Beliefs are Held about the Distances in which Vehicles Can Pull up in Emergencies. Here are Facts and Figures to Explode Them By L. J. Cotton

Is There a Future , for Air Cooling P—Contel.

a small potential power loss is incurred, in that the maximum usable engine temperature is not achieved, although, with pressure cooling, this fault can be rectified. In the case.of air cooling, overheating is much more likely to be experienced, and, in consequence, an even greater safety margin must be provided. The compression ratio employed in air-cooled units tends to be slightly lower than with water cooling.

Thermostatic Fan

An American patent describes a thermostatically controlled fan, and it is highly probable that a device of this nature would, if incorporated in a well-designed air-cooling system, help to cure the two faults found in the water-cooled arrangement.

The customary sheet-metal cowling would be used, and the air drawn over the cooling fins by a thermostatically controlled impeller. An excessive temperature would result in an increased air flow and vice versa.

Such a device would be advantageous in that thepower required to drive the impeller would be always the minimum, and not dependent on engine speed as is customary.

In Germany, much valuable work was done on air-cooling layouts, a tine example being the Krupp. On this make, longitudinal fins were employed, covered by a welldesigned cowling. The cylinder heads were finned to correspond with the cylinder blocks, and, in this case, the outer cowling was cast integral.

Phdttomen Engine

The Phhnomen engine had iron cylinders, a light-alloy head, and the rather low compression ratio of 5.3 to 1. Driven from the front end of the crankshaft was a large fan working in a volute casing which communicated with an air distribution trunk. The cooling air passed over the side valves and thence over vertical cylinder-head fins, and the usual circumferential cylinder fins. Baffles were employed to obtain adequate air flow over the side of the cylinders remote from the air flow.

Probably the most interesting feature was the temperature control which consisted of two butterfly control valves in the entry orifice to the fan. One of these valves was controlled by the throttle, a small opening resulting in reduced air flow, whilst, at higher speeds, ample cooling was provided. The second valve was operated thermostatically, the necessary capsule being positioned in the path of the exhaust cooling-air flow so that the delivery was suited to the demands of the engine.

B2

IWAS nipping smartly up the main road at 40 miles an hour, when a car suddenly shot out of a side turning. If I hadn't pulled up in my own length, I would have hit him broadside on."

That is the kind of loose remark one frequently hears from even experienced drivers, who should know better. It is possible that the distance quoted was intended merely to convey the impression of exceptional braking power. There is, however, a danger that many drivers really believe they are able to stop a vehicle in its own length from speeds in excess of 20 m.p.h.

Indeed, there are more illusions about braking performance than about any other aspect of vehicle performance, with the possible exception of average speeds.

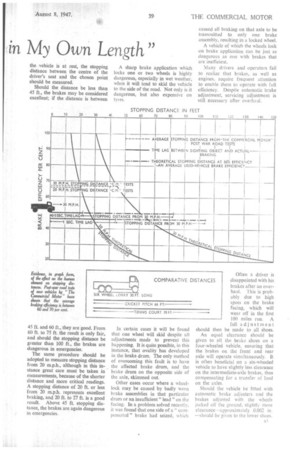

What are the facts? In the first place, assuming theoretically perfect braking performance, and making no allowance for the human element, the minimum distance in which a vehicle can pull up from 40 m.p.h. is 53.6 ft. Allowing 4 sec. for the driver to become aware of the danger and transfer his foot from the accelerator to the brake pedal, the distance is increased to 83 ft., and with a time lag of 1 sec. the distance becomes 102.5 ft.

What to Expect The highest braking efficiency that can be expected from a loaded vehicle under present conditions of maintenance and road surface is 60 per cent. In that case, the theoretical optimum stopping distance at 40 m.p.h. is 89.3 ft. A time lag of 4 sec. raises the figure to 118.7 ft. and of 1 sec. to 148 ft.

Even the driver of a "Queen Mary" with superlative braking characteristics will not pull up in the length of the vehicle from 40 m.p.h.

At 30 m.p.h. it is also not physically possible to halt a six-wheeled lorry in its own length. Allowing a time lag of 4 sec. and braking efficiency of 100 per cent., the stopping

distance from 30 m.p.h. is 52.2 ft. Therefore, if a lorry driver claims to have stopped in his own length, ridicule him—but make certain, first, that he was not driving a "Queen Mary " I

Unless the driver has already begun to apply the pedal, there must be a time lag before the brakes are operated. A 4-sec. delay in sighting an obstruction and operating the brake pedal is equivalent to travelling 22 ft. at 30 m.p.h. or 15 ft. at 20 m.p.h. before any brake force is applied.

Consequently, when travelling at any great speed, a driver has usually covered a vehicle's length before the brakes come into operation.

It is only at 20 m.p.h. that a driver of a six-wheeled lorry can genuinely be believed to have stopped in his own length. His stopping distance, assuming that his brakes were above standard, would be approximately 22 ft., which leaves a time lag of only sec. to make his story ring true.

Bad Evidence In certain instances drivers have been known to state in a court of law that they "pulled up in their own length." This has been pounced on immediately by the opposing side and has been used to prove a mis-statement in the driver's evidence.

Brake testing can be carried out in a simple manner, and if the stopping distance be measured, it can be converted to brake-efficiency readings by charts which may be obtained from brake-facing manufacturers.

To measure stopping distance it is best first to find a level stretch of road, preferably concrete-surfaced, with as light a traffic load as possible.

Accelerating to slightly over 30 m.p.h., allow the vehicle to slow down to 30 m.p.h. opposite a definite point such as a lamp-post or pillarbox, where the brakes should be fully

applied. It is preferable that the driver should apply the brakes when his body is actually in line with the chosen point, because this procedure ensures a more correct result. When

the vehicle is at rest, the stopping distance between the centre of the driver's seat and the chosen point should be measured.

Should the distance be less than 45 ft., the brakes may be considered excellent; if the distance is between 45 ft. and 60 ft., they are good. From 60 ft, to 75 ft. the result is only fair, and should the stopping distance be greater than 100 ft., the brakes are dangerous in emergencies.

The same procedure should be adopted to measure stopping distance from 20 m.p.h., although in this instance great care must be taken in measurements, because of the shorter distance and more critical readings. A stopping distance of 20 ft. or less from 20 m.p.h. represents excellent braking, and 20 ft. to 27 ft. is a good result. Above 45 ft. stopping distance, the brakes are again dangerous in emergencies.

A sharp brake application which locks one or two wheels is highly dangerous, especially in wet weather, when it will tend to skid the vehicle to the side of the road. Not only is it dangerous, but also expensive on tyres, In certain cases it will be found that one wheel will, skid despite all adjustments made to prevent this happening. It is quite possible, in this instance, that ovality has developed in the brake drum. The only method of overcoming this fault is to have the affected brake drum, and the brake drum on the opposite side of the axle, skimmed out.

Other cases occur where a wheellock may be caused by badly worn brake assemblies in that particular drum or an insufficient " lead " on the facing. In a problem solved recently, it was found that one side of a " compensated " brake had seized, which caused all braking on that axle to be transmitted to only one brake assembly, resulting in a locked wheel.

A vehicle of which the wheels lock on brake application can be just as dangerous as one with brakes that are inefficient.

Many drivers and operators fail to realize that brakes, as well as engines, require frequent attention to enable them to operate with full efficiency. Despite automatic brake adjustment, servicing adjustment is still necessary after overhaul.

Often a driver is disappointed with his brakes after an overhaul. This is probably due to high spots on the brake facing, which will wear off in the first 100 miles run. A full adjustment should then be made to all shoes.

An equal clearance should be given to all the brake shoes on a four-wheeled vehicle, ensuring that the brakes on the front and rear axle will operate simultaneously. It is often beneficial on a six-wheeled vehicle to have slightly less clearance on the intermediate-axle brakes, thus compensating for a transfer of load on the axles.

Should the vehicle be fitted with automatic brake adjusters and the brakes adjusted with the wheels jacked off the ground, slightly more clearance—approximately 0.002 in. —should be given to the lower shoes.