"Prefab." Units Form New Lightweight Body DREFABRICATED components . for

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

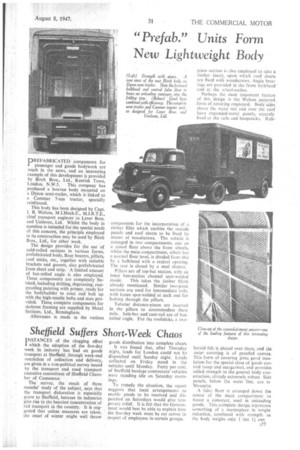

I passenger and goods bodywork are ranch in the news, and an interesting example of this development is provided by Birch Bros., Ltd„ Kentish Town,

London, N.W.5. This company has produced a boxvan body mounted on a Dyson semi-trailer, which is linked to a. Cornmer, 7-ton tractor, specialty reinforced.

This body has been designed by Capt. J. B. Walton, M.I.Mech.E., M.I.R.T.E., chief transport engineer to Lever Bros. and Unilever, Ltd. Whilst the body in question is intended for the special needs of this concern, the principle employed in its construction may be used by Birch Bros., Ltd.', for other work.

The design provides for the use of cold-rolled sections in various forms, prefabricated body, floor bearers, pillars, roof sticks, etc:, together with Suitable brackets and gussets, also prefabricated from sheet and strip. A limited amount of hot-rolled angle is also employed. These components are completely finished, including drilling, degreasing, rustproofing painting with primer, ready for the bodybuilder to erect and bolt up with the high-tensile bolts and nuts provided.. These complete components for skeleton framing are supplied by Metal Sections, Ltd., Birmingham.

Allowance is made in the various

components for the incorporation of a timber fillet which enables the outside panels and roof sheets to be fixed by means of woodscrews. The vehicle is arranged in two compartments, one on :a raised floor above the front wheels, whilst the main compartment, which has a normal floor-level, is divided from this by a bulkhead with a central opening,. The rear is closed by a steel shutter.

Pillars arc of top-hat section, with an inner box-section channel spot-welded inside. This takes the timber fillets already mentioned. Similar two-piece sections are used for intermediate rails, with knees spot-welded at each end for bolting through the pillars.

Tubular distance-pieces are inserted in the pillars to accommodate these rails. Sole-bar and-cant-rail are of hotrolled angle. For the roofsticks, a two piece section is also employed to take a timber insert, upon • which roof sheets are fixed with woodscrews.. Angle bi-:icings are provided in the front bulkhead and at the wheel-arches.

Perhaps the most imporiant feature of this design is the Walton patented . form of covering employed. Bocly—sids above the waist rail and over the roof have expanded-metal panels, securely fixed to the rails and hoopsticks. Rub