UPKEEP OF COMMERCIAL ELECTRIC VEHICLES.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

The Second Article.

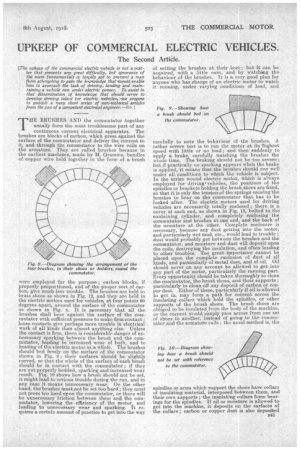

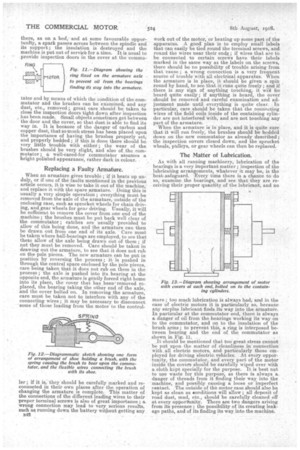

THE BRUSHES AND the commutator together usually form the most troublesome part of any continuous current electrical apparatus. The brushes are blocks of carbon, which press against the surface of the commutator and deliver the current to it, and through the commutator to the wire coils on the armature. They are called brushes because in the earliest machines, made by M. Gramme, bundles ' of copper wire held together in the form of a brush were employed for the purpose ; carbon blocks, if properly proportioned, and of the proper sort of carbon, give much less trouble. The brushes are held in brass shoes as shown in Fig. la, and they are held in the electric motors used for vehicles5 at four points 90 degrees apart, around the surface of the commutator as shown in Fig. 8. It is necessary that all the brushes shall bear 'against the surface of the commutator with sufficient pressure to make firm contact ; loose contacts give perhaps more trouble in electrical work of all kinds than almost anything else. Unless the contact is firm, there is considerable danger of unnecessary sparking between the brush and the commutator, leading to increased wear of both, and to heating of the electric motor as a whole. The brushes should bed firmly on the surface of the commutator shown in Fig. 9; their surfaces should be slightly curved, so that the whole of the surface of each brush should be in contact with the commutator ; if they are not properly bedded, sparking and increased wear result. Fig. 10 shows how a brushshould not be set, it might lead to serious trouble during the run, and in any case it means unnecessary wear. On the other hand, the brushes must not be set too hard ; they must not press too hard upon the commutator, or there will be unnecessary friction between them and the commutator, lowering the efficiency of the motor, and leading to unnecessary wear and sparking. It requires a certain amount of practice to get into the way

of setting the brushes at their best ; but it can be acquired, with a little care, and, by watching the behaviour of the brushes. It is a very good plan for anyone who has _charge of an electric motor to watch it . running, under varying conditions of load, and

carefully to note the behaviour of the brushes. A rather severe test is to run the motor at its 'highest speed with little or no load ; and then suddenly to apply a, brake, carefully watching the brushes the whole time. The braking should not be too severe; but if practically no sparking appears when the brake is applied, it means that the bashes should run well under all conditions to which the vehicle is subject. In the series wound electric motor, Which is always employed for driving. vehicles, the positions of the spindles or brackets holding the brush shoes are fixed, so that it is only the tension-of the springs causing the brushes to bear on the commutator that has to be looked after. The electric motors used for driving vehicles are necessarily totally enclosed ; there is a cover at each end,. OA shown in Fig. 13, bolted to the containing cylinder, and completely enclosing the commutator and brushes at one end, and the back of the armature at the other. Complete enclosure is necessary, because any dust getting into the motor, and particularly wet mud, etc., would lead to trouble ; dust would probably get between the brushes and the commutator, and moisture and dust will deposit upon the coils, destroying the insulation, and often leading to other troubles. Too great importance cannot be placed upon the complete exclusion of dust of all kinds, and particularly of metal dust, and of oil. Oil should never on any account be allowed to get into any part of the motor, particularly the running part. Every opportunity should be taken thoroughly to clean . the commutator, the brush shoes, and their supports ; particularly to clean off any deposit of carbon or copper dust. Either of these, particularly if oil is allowed to get in, may form a path for current across the insulating collars which hold the spindles, or other supports of the brush shoes. The brush shoes are obliged to be insulated from the body of the machine, or the current would simply pass across from one set of shoes to another, instead of going to the commutator and the armature coils ; the usual method is, the

spindles or arms which support the shoes have collars of insulating material, interposed between them, and their own supports ; the insulating collar form bearings for the spindles. If oil or moisture is allowed to get into the machine, it deposits on the surfaces of the collars; carbon or copper dust is also deposited there, as on a bed, and at some favourable opportunity, a spark passes across between the spindle and its support ; the insulation is destroyed and the machine is put out of service for a time. It is usual to provide inspection doors in the cover at the •commu tator end by means of which the condition of the commutator and the brushes can be examined, and any dust, etc., removed ; great care should be taken to closi the inspection doors tight down after inspection has been made. Small objects sometimes get between the door and the cover, so that dust is able to find its way in. It is because of the danger of carbon and copper dust, that so much stress has been placed upon the importance of having the brushes properly set, and properly bedded ; if this is done there should be. very little trouble with either ;• the wear of the brushes should be very slight, and also of the commutator; a well-cared-for commutator assumes a bright polished appearance, rather dark in colour.

Replacing a Faulty Armature.

When an armature gives trouble ; if it heats up unduly, or if one of the faults mentioned in the previous article occurs, it is wise to take it out of the machine,and replace it with the spare armature. Doing this is usually a very simple operation; everything must be removed from the axle of the armature, outside of the enclosing case, such as sprocket wheels for chain driving, and, gear wheels for gear driving. Usually, it will be sufficient to remove the cover from one end of the machine ; the brushes must be put back well clear of the commutator ; catches are usually provided to allow of this being done, and the armature can then be drawn out from one end of its axle. Care must be taken where ball-bearinr are employed, to see that these allow of the axle being drawn out of them ; if not they must be removed. Care should be taken in drawing out the armature, to see that it does not rub on the pole pieces. The new armature can be put in position by reversing the process ; is pushed in through the central space enclosed by the pole pieces, care being taken that it does not rub on them in the process ; the axle is pushed into its bearing at the opposite end, the armature is gently forced right home into its place, the cover that has ,been removed replaced, the bearing taking the other end of the axle, and the cover bolted on. In removing the armature, care must be taken not to interfere with any of the connectingwires ; it may be necessary to disconnect some of .those leading from the motor to the control

ler ; if it is, they n should be carefully marked and re connected in their own places after the operation of changing the armature is complete. This matter of the connections of the different leading wires to their proper terminal screws is also of great importance ; a wrong connection may lead to very serious results, such as running down the battery without getting any n42 work out of the motor, or heating up some part of the apparatus. A good plan is-to employ small labels that can easily be tied round the terminal screws, and round the wires near their end; if wires that are to be connected to certain screws have their labels marked in the same way as the labels on the screws, there should be no possibility of trouble arising from that cause ; a wrong connection is a very frequent source of trouble With all electrical apparatus. When the armature is in place it should be given a spin round by hand, to see that it runs quite freely ; and if there is any sign of anything touching, it will be beard quite easily; if anything is heard, the cover should be removed and careful examination and adjustment made until everything is quite clear. In particular, care should be taken that the connecting wires of tke field coils inside of the 'containing cylin-. der are not interfered with, and are not touching any part of the armature.

• When the armature is in place, and it is quite sure that it will run freely; the brushes should be bedded down on the. new commutator as already. described ; the inspection covers closed down, and the sprocket wheels, pulleys, or gear wheels can then be replaced.

The Matter of Lubrication.

As with all running machinery, lubrication of the bearings is a very important matter ; inspection of the lubricating arrangements, whatever it may be, is. the best safeguard. Every time there is a chance to do so, examine the bearings, and see that they are receiving their proper quantity, of the lubricant, and no more ; too much lubrication is always bad, and in the case of electric motors it is particularly so, because any surplus lubricant finds its way into the armature. In particular at the commutator end, there is always a danger of oil from the bearings working its way on to the commutator, and on to the insulation of the brush arms ; to prevent this, a ring is interposed between bearing and the end of the commutator as shown in Fig. IL ,

It should be mentioned that too great stress cannot be put upon the matter of cleanliness in connection. with all electric motors, and particularly those employed for driving electric vehicles. . At every opportunity, the commutator, and every part of the motor inside' the covers lihould be carefully wiped over with a, cloth kept specially for the purpose. It is best not to Use waste for this purpose. as there is always a danger of threads from it finding their way into the

• machine, and possibly causing a loose or. imperfect contact. The outside of the motor case should also be kept as clean as conditions will allow ; all deposit of road dust, mud, etc., should be carefully cleaned Off at every opportunity. There are two dangers arising from its presence ; the possibility of its creating leakage paths, and of it finding its way into the machine.