British with an American Twang

Page 48

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

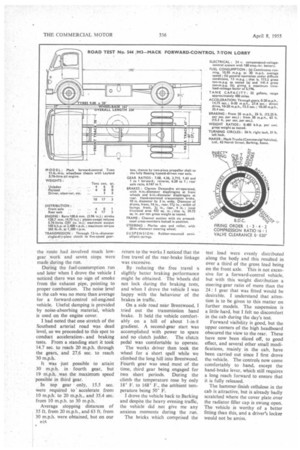

Latest Mack Forward-control 7-tonner has Leyland Running Components and American-type Accessories: 16 m.p.g. at 30 m.p.h. Average Design Permits .Easy Maintenance By John Savage, A.I.R.T.E. SEVERAL features that are popular on American vehicles are now available on a British-built lorry. Mack Trucks (Commercial Vehicles), Ltd., Barking, Essex, who built their first vehicle in August, 1954, have now produced a forwardcontrol 7-tonner.

It has air-operated brakes, a transmission parking brake, Air-operated windscreen wipers and horns, and an airline connection in the cab for inflating the tyres. The semi-elliptic . springs at front and rear are rubbermounted on the chassis.

The vehicle I tested was the third to be built by the company. The first two were of the normal-control type, and a road-test report on one of these appeared in The Commercial Motor on August 13, 1954. The latest model varies in many respects from the first two.

Leyland Components

It has a forward-control cab and is powered by a Leyland 0350 5.76-litre engine rated at 105 b.h.p. at 2,400 r.p.m.; maximum torque is 265 lb.-ft. at 1,300 r.p.m. An Albion GB.236H five-speed gearbox is used with a Leyland 13-in.-diameter clutch. Other Leyland components include the radiator and the engine bearers.

The rear-axle drive employs hypoid gearing, which is housed in a fabricated steel pressing. The twopiece propeller shaft has a Layrub coupling at the rear end and Hardy Spicer needle-roller bearings at the other joints. The chassis frame is fabricated from channel section longitudinals 9 in. deep and 31 in. wide, with six pressed-steel crossmembers bolted in position.

Rubber-mounted Springs

The engine and gearbox are mounted as a unit on flexible-link units at the rear, and rubber sandwich blocks at the front. The ends of the main leaves of the semi-elliptic springs are trapped between large rubber blocks. No spring eyes are necessary, and the spring mountings require no greasing or other maintenance.

The brakes are operated by air pressure supplied from a Clayton Dewandre compressor of 7/ cu. ft. capacity, driven in tandem with the injection pump. The band-type transmission hand brake is situated at the centre bearing of the propeller shaft.

Steering is by Mantes cam and roller gear in conjunction with a

20-in.-diameter steering wheel. A Bonallack all-metal cab and a nt4

Dekalloy drop-sided body was fitted to the test vehicle.

Winking-light traffic indicators are included in the C.A.V. electrical equipment. Compressed air is used to operate the variable-speed windscreen wipers, which are of Westinghouse manufacture, and strident, air-operated horns are fitted. A compressed-air point is provided in the cab to which a hose can be coupled to supply air for tyre inflation and other purposes. A Norway recirculatory-type cab heater made by the Key Leather Co., Ltd., is flush-fitted under the control panel:

As the vehicle employs many proprietary items, I was anxious to see that routine maintenance of these units had not been impeded in any way. I first looked at the location of the points for topping-up fluid levels, in the battery, radiator, sump, gearbox and back axle, to satisfy myself that they were all accessible.

I then spent 20 minutes checking the respective levels and topping-up.

Nearly half of this time was involved in removing and replacing the battery covers, which are situated behind the cab at chassis level.

An extension has been fitted to the engine dipstick, so that it can be removed through an aperture in the cab floor. The extension makes the dipstick look clumsy, but I found that it was simple to remove and replace.

An advantage of the rubber mountings for the springs is a reduction in the time required to grease the Mack chassis. The steering-gear grease points are easy to reach, especially when the .front axle is jacked up, and as air brakes are fitted the task of bleeding the system, as is necessary with hydraulic brakes, is obviated. Slack adjusters are used, so that adjusting the brakes takes about 20 minutes.

I next removed the engine valve cover‘to satisfy myself that the injectors could be easily extracted without employing special tools. I also

hecked that each rocker could be aached to adjust tappet clearances.

Removal of the element from the all-flow type of engine-oil filter equired a little patience, as one of hie nuts securing the cover was artly concealed by the rear engine earer. The complete task of renewig the element took 30 minutes.

Turning to the oil-fuel filters, I vas pleased to find that the primary Liter was mounted on the outside of he chassis frame, where it can easily re reached. The main filter, which mounted on the engine cylinder lead, can also be serviced without rouble. This filter is fitted with a ;ravity vent valve that simplifies Priming after replacing the filter tement.

I estimate that a fitter would be ble to do all these jobs thoroughly n about four hours.

The Commercial Motor road tests lemand that the course chosen for ach test should include a straight tretch of level road, at least one ong hill, and a steep hill. From wevious experience in the southern )art of Essex, I knew that the first )f these requirements would be lifficult to satisfy, so while looking or a suitable length of road I carried )ut the fuel-consumption test on a .un of 33 miles.

This started at the junction of the iouthend arterial and Colchester .oads, where I disconnected the fuel .eturn pipe to the tank, to allow the 'uel to drain off to the level of he connection. As the fuel-tank ;apacity was 32 gallons and its ength about 3 ft., it was important

o conduct the fuel-measuring pro:edure with extreme care, as a slight lifference in the level of the vehicle )r of the fuel in the tank would have lad a great influence on the result.

Satisfied that the fuel level had settled, the works representative connected the return pipe to the tank while I marked the road so that we could be sure to stop the vehicle in exactly the same place on our return. The test route took us for about five miles along the Southend road, when we turned left into Brentwood, and along the Colchester Road and so back to the starting point. Here we circuited the roundabout and set off in the opposite direction on the same triangular course. We pulled up at our mark after 681 minutes had elapsed, 21 minutes of which were spent at various traffic stops, mainly in Brentwood. It was necessary to add only 161 pints of fuel to the tank to cause it to drip from the return-pipe connection.

This represented a fuel-consumption rate of 15.95 m.p.g. at an average speed of 30 m.p.h. after allowing for stops. This figure was better than I expected, for although we were carrying less than 7 tons, the route had involved much lowgear work and seven stops were made during the run.

During the fuel-conSumption run and later when I drove the vehicle I noticed there was no sign of smoke from the exhaust pipe, pointing to proper combustion. The noise level in the cab was no more than average for a forward-control oil-eng;ned vehicle. Useful damping is provided by noise-absorbing material, which is used on the engine cover.

I had noted that one stretch of the Southend arterial road was dead level, so we proceeded to this spot to conduct acceleration-, and braking tests. From a standing start it took 14.7 sec. to reach 20 m.p.h. through the gears, and 27.6 sec. to reach 30 m.p.h.

It was just possible to attain 30 m.p.h. in fourth gear, but 19 m.p.h. was the maximum speed possible in third gear.

In top gear only, 15.5 sec. were required to' accelerate from 10 m.p.h. to 20 m.p.h., and 35.4 sec. from 10 m.p.h. to 30 m.p.h.

Average stopping distances of 35 ft. from 20 m.p.h., and 63 ft. from 30 m.p.h. were obtained, but on our return to the works I noticed that the free travel of the rear-brake linkage was excessive.

By reducing the free travel a sligfftly better braking performance might be obtained. The Wheels did not lock during the braking tests, and when I drove the vehicle I was happy with the behaviour of the brakes in traffic.

On a side road near Brentwood, I tried out the transmission hand brake. It held the vehicle comfortably on a hill of about 1-in-8 gradient. A second-gear start was accomplished with power to spare and no clutch judder. The clutch pedal was comfortable to operate.

The works driver then took the wheel for a short spell while we climbed the long hill into Brentwood. Fourth gear was used most of the time, third gear being engaged for two short periods. During the climb the temperature rose by only 18° F. to 168° F., the ambient temperature being 50° F.

I drove the vehicle back to Barking and despite the heavy evening traffic, the vehicle did not give me any anxious moments during the run.

The bricks which comprised the test load were evenly distributed along the body and this resulted in over a third of the gross load being on the front axle. This is not excessive for a forward-control vehicle, but with this weight distribution a steering-gear ratio of more than the 24: 1 gear that was fitted would be desirable. I understand that attention is to be given to this matter on further models. The suspension is a little hard, but I felt no discomfort in the cab during the day's test.

Forward visibility is good, but the upper corners of the high headboard obscured the view to the rear. These have now been sliced off, to good effect, and several other small modifications, mainly in the cab, have been carried out since I first drove the vehicle. The controls now come comfortably to hand, except the hand-brake lever, which still requires a long reach forward to ensure that it is fully released.

The hammer-finish cellulose in the cab is attractive, but is already badly scratched where the cover plate over the radiator filler cap is swung open. The vehicle is worthy of a better fitting than this, and a driver's locker would not be amiss.