BUILT TO LAM A.E.C. EIGHT-WHEELER

Page 20

Page 21

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

By L. J. COTTON, M.1.R.T.E.

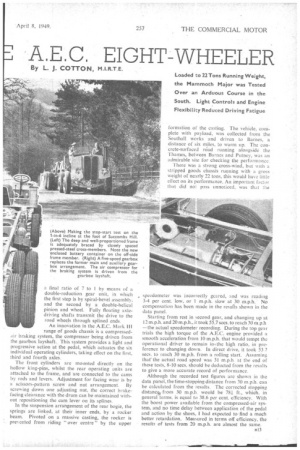

CONSTRUCTION of the frame, suspension, transmission and other components of the A.E.C.-Mammoth Major eight-wheeled goods chassis shows that it is built to last. Of 12-in, depth, and with wide flanges, the heavy side members are held rigid by eight pressed-steel cross members spaced at

regular intervals throughout the length of the frame. ,

. -One• of the A.E.C. Mark III range, the test chassis was powered by the 9.6-litre direct-injection unit. A heavy-duty single-dry-plate clutch unit is , employed, having a conventional toggle-leVer withdrawal mechanism. A clutch i

. fitted and oinr sates on a drum attached to the gearbox layshaft.

The five-speed gearbox on the latest models replacesthe former arrangement of fourspeed main and auxiliary gearbox. Of unit construction with the engine, the assembly is supported by a banjo member fitted to the chassis frame. The gearbox casing is an aluminium-alloy casting, which incorporates an inspection cover for the clutch assembly. Spur gears are used throughout the gearbox, the first and reverse speeds being of sliding-mesh pattern, whilst the four higher ratios are in constant mesh.

A feature of the gearbox design is the method eri?loyed to afford a light gear change. The teeth of the splined hubs on which the dogs for the four upper iatios slide, are under-cut at the centre to a pure 20 degrees involute profile. The outer lengths of the teeth are of bastard profile, and approximately 0.016 in. thicker on the pitch line. With any of these ratios engaged, the gears are operating on the centre position of the teeth, and to jump out of gear, the dog has first to ride over an 0.008-in. step. Therefore, the tendency for the gears to disengage is counteracted without employing heavy selector plunger springs.

As the test machine was a home model, it was equipped with a single drive to the third axle, the final axle being a trailed unit. This single-drive axle provides al2

a final ratio of 7 to 1 by means of a double-reduction gear unit, in which the first step is by spiral-bevel assembly, and the second by a double-helical pinion and wheel. Fully floating axledriving shafts transmit the drive to the road wheels through splined ends.

An innovation in the A.E.C. Mark Ill range of goods chassis is a compressedair braking system, the compressor being driven from the gearbox layshaft. This system provides a light and progressive action at the pedal, which actuates the six individual operating cylinders, taking effect on the first, third and fourth axles.

The front cylinders are mounted directly on the hollow king-pins, whilst the •rear operating units are attached to the frame, and are connected to the cams by rods and levers. Adjustment for facing wear is by a scissors-pattern Screw and nut arrangement. By screwing down one adjusting nut, the correct brakefacing clearance with the drum can be maintained without repositioning the cam lever on its splines.

In the suspension arrangement of the rear bogie, the springs are linked, at their inner ends, by a rocker beam. Pivoted on a massive casting, the rocker is prevented from riding "over centre" by the tipper formation of the casting. The vehicle, complete with payload, was collected from the Southall works and driven to Barnes, a distance of six miles, to warm up. The concrete-surfaced road running alongside the Thames, between Barnes and Putney, was an admirable site for checking the performance.

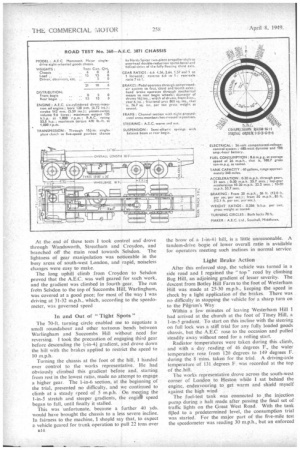

There was a strong cross-wind, but with a stripped goods chassis running with a gross weight of nearly 22 tons, this would have little effect on its performance. An important factor that did not pass unnoticed, was that the • speedometer was incorrectly geared, and was reading 3-4 per cent. low, or 1 m.p.h slow at 30 m.p.h. No compensation has been made in the results shown in the data panel.

Starting from rest in second gear, and changing up at 12 m.p.h. and 20 m.p.h., it took 55.7 secs. to reach 30 m.p.h —the actual speedometer recording. During the top gear trials the high torque of the A.E.C. engine provided a smooth acceleration from 10 m.p.h. that would tempt the operational driver to remain iO4 the high ratio, in preference to changing down. In direct drive, it took 53 7 secs. to reach 30 m.p.h. from a rolling start. Assuming that' the actual road speed was 31 m.p.h. at the end of these tests, 8-10 secs. should be deducted from the results to give a more accurate record of performance.

Although the recorded test figures arc shown in the data panel, the time-stopping distance from 30 m.p.h. can be calculated from the results. The corrected stopping distanciv from 30 m.p.h. would be 781 ft., which, in general terms, is equal to 38.6 per cent. efficiency. With the boost power available from the compressed-air system, and no time delay between application of the pedal and action by the shoes, I had expected to find a much better retardation. Measured in terms off efficiency, the results of tests from 20 m.p.h. are almost the same.

At the end of these tests I took control and drove through Wandsworth. Streatham and Croydon, and branched off the main road towards Selsdon. The lightness of gear manipulation was noticeable in the busy areas of south-west London, and rapid, noiseless changes were easy to make.

The long uphill climb from Croydon to Selsdon proved that the A.E.C. was well geared for such work, and the gradient was climbed in fourth gear. The run front Selsdon to the top of Succombs Hilt, Warlingham, was covered at a good pace; for most of the way I was driving at 31-32 m.p.h., which, according to the speedometer, was governed speed In and Out of "Tight Spots" The 70-ft. turning circle enabled me to negotiate a small roundabout and other tortuous bends between Warlingham and Succombs Hill without need for reversing. J took the precaution of engaging third gear before descending the 1rin-41 gradient, and drove down the hill with the brakes applied to restrict the speed to 10 m.p.h.

Turning the chassis at the foot of the hill, I handed over control to the works representative. He had obviously climbed this gradient before and, starting from rest in the lowest ratio, made no attempt to engage a higher gear. The l-in-6 section, at the beginning of the trial, presented no difficulty, and we continued to climb at a steady speed of 5 m.p.h. On meeting the 1-in-5 stretch and steeper gradients, the engidt speed began to fall, until finally it stalled.

This was unfortunate, because a further 40 yds. would have brought the chassis to a less severe incline. In fairness to the machine, I should say that, to expect n vehicle geared for trunk operation to pull 22 tons over B14 the brow of a 1-in-41 hill, is a little unreasonable. A tandem-drive bogie of lower overall ratio is available for operators meeting such inclines in normal service;

Light Brake Action After this enforced stop, the vehicle was turned in a side road and I regained the " top " road by climbing Bug Hill, an adjoining gradient of lesser severity. The descent from Botley Hill Farm to the foot of Westerham Hill was made at 25-30 m.p.h., keeping the speed in check by a light application of the brakes. There was no difficulty in stopping the vehicle for a sharp turn on to the Pilgrim's Way

Within a few minutes of leaving Vesterham Hill I had arrived at the church at the foot of Titsey Hill, a 1-in-5 gradient. 7'o start on this incline with the steering on full lock was a .stiff trial for any fully loaded goods chassis, but the A.E.0 rose to the occasion and pulled steadily away without need for a rolling start.

Radiator temperatures were taken during this climb, and with a day reading of 46 degrees F., the water temperature rose from 120 degrees to 149 degrees F. during the 8 .mins.. taken for the trial. A driving-axle temperature of 131 degrees F. was recorded at the top of the-hill.

The works representative drove across the south-west corner of London to Heston while I sat behind the engine, endeavouring to get warm and shield myself against the high wind.

The fuel-test tank was connected to .the injection pump during a halt made after passing the final set of traffic lights on the Great West Road. With the tank filled to a predetermined level, the consumption trial was started. For the major part of the five-mile test the speedometer was reading 30 m.p.h., but an enforced

halt was made at the traffic lightsat Ashford. The

meter clicked over to the five-mile mark just before reaching Staines, and the chassis was brought to rest to measure the quantity of fuel used.

It required 0.58 gallon of fuel to replenish the tank to the original level, and this gave a consumption corresponding to 8.6 m.p.g. at an average speed of 26 m.p.h. Allowing for the speedometer inaccuracy, the true results would he 8.9 m.p.g. at a speed of 26.9 m.p.h.

After this trial the course was retraced to Southall, which was the end of the 84-mile test. A fair propor tion of that distance was covered under most adverse conditions for this class of vehicle, but apart from the exceptionally difficult climb of Succombs Hill there was no reason to doubt that the A.E.C. could "take it.

The worm-and-nut steering, operating on the two front axles, provides relatively light control, especially at any speed above 12 m.p.h. When turning at the end of the acceleration trials and at Succombs Hill, slightly more force was required to move the steering wheel than with a normal single front axle, otherwise the effort required was no greater than that needed to drive a four-wheeled machine.