IMPROVEMENTS in . Sus p ens

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

RE OVERDUE

Is Independent Springing the Answer ?

By R. W. Bent, M.I.Mech.E.

IN surveying the progress of commercial-vehicle design it is noticeable that, in addition to a steady advance over a period of years, there are occasional rapid changes Two of the " surprise developments have included the introduction of the compressionignition engine and four-wheel

braking. In many eases these developments have been encouraged by competition between manufacturers to supply a vehicle which is more economical or better in some other respect • The suspension system would appear to be a feature that is now due for improvement, because of the demands for increased comfort and to deal with road surfaces that are likely to suffer from inadequate maintenance for some years to come.

The fact that the semi-elliptic spring used on the majority of vehicles has remained practically unchanged for Many years would suggest that it has many features in its favour This is to some extent true, because, in addition to its function as a spring, it acts as a torque member, besides giving greater support to the chassis than other forms of suspension Moreover, it is reasonably cheap and maintenance is simple and inexpensive.

Problems to be Faced It therefore follows that any alternative must at least be equal to the semi-elliptic spring in respect of cost and rigidity Although new methods are popular on private cars, they cannot always be applied with equal success to the commercial vehic

It must be admitted that the problem facing . the commercialvehicle designer is more difficult than that confronting his colleague on the car side rake the question of load, which on a car may vary from one to five passengers, but on a bus is considerably greater The suspension of a double-decker has to be consistent for a load of, perhaps, two to 56 passengers.

Again, road surfaces in this at, country range from tarmacadamsometimes good, but often the worse for wear after the neglect of the war years—to granite setts. Speeds are varying, and a suspension system which is satisfactory in urban areas may be uncomfortable on relatively high-speed inter-town services.

A further factor to consider is that it is not easy to formulate standards of comfort, as one person may prefer a relatively " feather-bed " suspension, which to another would induce unpleasant symptoms, Undoubtedly, on double-deck buses, roll causes more criticism than the amount of vertical movement.

The ideal condition is one in which the wheels follow the contour of the road surface and maintain uniform contact with it, and the sprung portion of the chassis travels without vertical movement, rolling or pitching.

If it be admitted that the semielliptic Spring has reached the limit of its development, what possibilities does independent suspension offer?

On private cars, independent suspension has been applied mainly to the front end, because it was found

that large deflections with the normal axle caused reactions on the steering, making the car difficult to control This argument has less force in relation to commercial vehicles, because their lower speeds and thelact that the rear axle carries a greater share of the load.

Independent suspension is superior in resisting roll. This may be observed from a comparison of the • distance of the" roll base," which; in the case of conventional chassis, is measured across the spring anchorage, whereas with independent suspension this distance is virtually equal to the wheel track. • The Absorbing of Rebound

A factor which affects the behaviour of any suspension system is the amount of unsprung weight. When a wheel meets an obstruction the upward force is proportional to the unsprung weight acting on that wheel. This force compresses the spring, which then returns the wheel with such force that further vibrations of gradually decreasing intensity occur. Shock absorbers are employed to reduce these subsequent rebounds.

By reducing the unsprung weight, the initial force, and consequently the subsequent forces, are diminished and the independent suspension, by displacing the orthodox axle beam, affords an appreciable saving in unsprung weight.

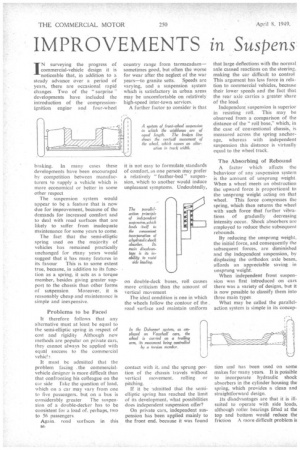

When independent front suspension was first introduced on cars there was a variety of designs, but it is now possible to classify them into three main types.

What may be called the parallelaction system is simple in its coneep tian and has been used on some makes for many years. It is pogsible to incorporate hydraulic shock absorbers in the cylinder housing the spring, which provides a clean and straightforward design.

Its disadvantages are that it is illsuited to operate with side loads, although roller bearings fitted at the top and bottom would reduce the friction A more difficult problem is that, as the wheel rises and falls, the distance between the steering arm and the track rod varies, which causes reactions on the steering gear.

The second form of independent suspension, usually known as the wishbone system, employs either leaf or coil springs, the preference being for the latter in recent designs. The wishbones may be of equal length, in which case the wheels move vertically, but with an alteration in the track, which may cause increased tyre wear.

For this reason, a top link shorter than the bottom is preferred. This allows the track to remain constant when the wheel-meets an obstruction. Slight tilting of the wheel occurs, but this is not detrimental in practice and would not be noticeable on commercial vehicles.

It is interesting to note that the new "Midland Red" design employs this system, in conjuhction with coil springs. As an alternative to coil or leaf springs, torsion bars are successfully employed by some makers.

The third type is usually known as the Dubonnet system, of which the chief exponent in this country is the Vauxhall concern. The wheel is carried on a trailing arm, movement of which is controlled by a torsion bar. Although fewer bearings are needed than with the wishbone system, they are heavily loaded, which would be a disadvantage in the case of commercial vehicles.

The choice for the commercialvehicle designer would appear to lie between the parallel type and the wishbone system, with the scales probably weighted in favour of the latter. Before embarking on such a development, the manufacturer and the operator will both need to be satisfied that durability will not be inferior to that of the existing semielliptic spring.

Many independent systems have not proved satisfactory in this respect, as wear in the various link bearings can have a cumulative effect on the steering and road-holding capabilities. Adequate bearing areas,

combined with efficient sealing to . prevent the ingress of dirt, should mitigate criticisms on this score. The reason why independent springing has been confined to the front end of cars has...already been given, but on commercial vehicles the arguments have not the same force. In fact, the rear axle would appear . to be the better location, for inde

• pendent springing, because it is here that increased deflation, plus greater roll resistance, will be most appreciated.

This would, of course, introduce the added complication of providing the driving shafts with universal joints to meet the requirements of wheels which move independently. The alternative would be to use front-wheel drive, which eases the problem of rear suspension.