MAKING BEST USE OF THE FORD.

Page 24

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which Will Appeal to the Owner, Driver and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are employed for commercial purposes, we endeavour to deal with the subject from every view-point, so that the advice given will appeal to the owner, driver, maintenance engineer or mechanic.

We shall welcome for inclusion among the hints those which have proved of value to individual users.

Readers are recommended to obtain the original "Book of the Ford," which constitutes a complete manual dealing with the Ford ear, the van and the truck. 2s. 9d. post free from the offices of this journal.

185.—Preventing Oil Leakage from the Axle of the Ton Truck.

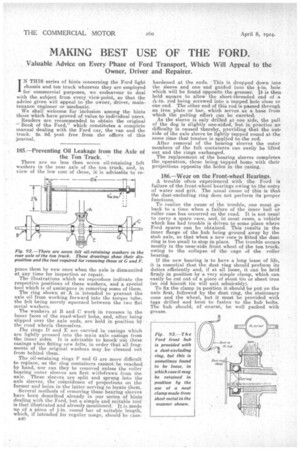

There are no less than seven oil-retaining felt washers in the rear axle of the ton truck, and, in view of the low cost of these, it is advisable to re place them by new ones when the axle is dismantled at any time for inspection or repair.

The illustrations which we reproduce indicate the respective positions of these washers, and a special tool which is of assistance in removing some of them. The ring shown at...A is intended to prevent the axle oil from working forward into the torque tube. the felt being merely squeezed between the two flat metal washers.

The washers at B and C work in recesses in the inner faces of the road-wheel hubs, and, after being slipped over the axle ends, are held in position by the road wheels themselves.

The rings D and E are carried in casings which are lightly pressed into the main axle casings from the inner sides.It is advisable to knock out these casings when fitting new felts, in order that all fragments ofthe original washers may be cleaned out from behind them.

The oil-attaining rings F and G are more difficult to replace, as the ring containers cannot: be reached by hand, nor can they be removed unless the roller bearing outer sleeves are first withdrawn from the axle. These sleeves are split and sprung into the axle sleeves, the coincidence of projections on the former and holes in the latter serving to locate them.

Several methods of removing these bearing sleeves have been described already in our series of hints dealing with the Ford, but a simple and suitable tool is that illustrated and already mentioned. It is.made up of a piece of n. round bar of suitable length, which, if intended for regular usage, should be ease B40

hardened at the ends. This is dropped down into the sleeve and one end guided into the fin, hole which -will be found opposite the greaser. It is then held square to allow the short-threaded end of a

rod being screwed into a tapped hole close to one end. The other end of this rod is passed through an iron plate or bar, which serves as a. base from which the pulling effort can be exerted. As the sleeve is only drilled at one side, the pull of the dog is slightly one-sided, but in practice no difficulty is caused thereby, providing that the outside of the axle sleeve be lightly tapped round at the same time that tension is applied to-the rod.

After removal of the bearing sleeves the outer members of the felt containers can easily be lifted out and the rings exchanged.

The replacement of the bearing sleeves completes the operation, these being tapped home with their projections opposite the holes in the casing.

186.—Wear on the Front-wheel Bearings.

A trouble often experienced with the Ford is failure of the front-wheel bearings owing to the entry of water and grit. The usual cause of this is that the dust-excluding ring does not perform its proper functions.

To realize the cause of the trouble, one must go back to a time when a failure of the inner ball or roller case has occurred on the road. It is not usual to carry a spare race, and, in most eases, a vehicle which has had trouble is driven to some place where Ford spares can be obtained. This results in the inner flange of the hub being ground away by the stub axle, so that when a new race is fitted the dust ring is too small to stop in place. The trouble occurs mostly in the near-side front wheel of the ton truck, owing to the collapse of the cage of the roller bearing.

If the new bearing is to have a long lease of life, it is essential that the dust ring should perform its duties efficiently and, if at all loose, it can be held firmly in position by a very simple clamp, which can easily be cut out of a piece of stout tin or sheet iron (an old biscuit tin will suit admirably).

To fix the clamp in position it should be put on the axle first, followed by the dust ring, the stationary cone and the wheel, but it must be provided with tags drilled and bent to fasten to the hub bolts. The hub should, of course, be well packed with grease.