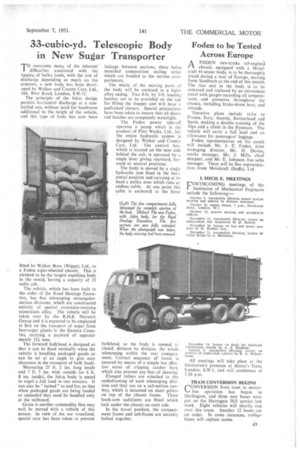

33-cubic-yd. Telescopic Body in New Sugar Transporter

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

TO overcome many of the inherent difficulties associated with the tipping of bulky loads, with the rate of discharge depending so much on the contents, a new body has been developed by Walker and County Cars, Ltd., 166, Weir Road, London, S.W.12.

The principle of the Jekta design permits horizontal discharge at a controlled rate, without need for headroom additional to the height of the vehicle, and this type of body has now been fitted by Walker Bros. (Wigan), Ltd., to a Foden eight-wheeled chassis. This is claimed to be the largest expelling body in the world, having a capacity of 33 cubic yds.

The vehicle, which has been built to the order Of the Road Haulage Executive, has five telescoping rectangularsection divisions, which are constructed entirely of special corrosion-resisting aluminium alloy. The vehicle will be taken over by the R.H.E. Norwich Group and it is expected to be employed at first on the transport of sugar from beet-sugar plants in the Eastern -Counties, carrying a payload of approximately 124, tons.

The forward bulkhead is designed so that it can be fixed vertically when the vehicle is handling packaged goods or can be set at an angle to give easy clearance in the transport of bulk loads.

Measuring 23 ft. 2 ins, long inside and 7 ft. 5 ins, wide outside (or 6 ft. 8 ins. inside), the Jekta body is stated to expel a full load in two minutes, It can also be " inched" to and fro, so that when packaged goods are being loaded or unloaded they need be handled only at the tailboard.

Grain is another commodity that may well be moved with a vehicle of this nature. • In view of the use visualized, special care has been taken to prevent leakage between sections, there being moulded composition sealing strips which are bonded to the section compartments.

The whole of the moving parts of the body will be enclosed in a lightalloy casing. Two 8-ft. by 3-ft. loading hatches are to be provided on the top for filling the hopper and will have a padlocked closure. Special precautions have been taken to ensure that all doors and hatches are completely watertight.

The Foden power take-off operates a pump which is the product of Pilot Works, Ltd., but the entire hydraulic system 'is designed by Walker and County Cars, Ltd. The control box, which is located on the near side behind the cab, is operated by a single lever giving rearward, forward or neutral positions.

The body is moved by a single hydraulic ram fixed in the horizontal position and carrying at its head a pulley over which runs an endless cable. At one point this cable is anchored to the front bulkhead, so the body is opened or closed, division by division, the whole telescoping within the rear compartment. Correct sequence of travel is ensured by means of a simple but effective series of tripping ratchet bars, which also prevent any fear of skewing.

Flanged rollers are attached to the underframing of each telescoping division and they run on a rail-section runway, which is mounted on short pillars on top of the chassis frame. Three hook-arm stabilizers are fitted which lock under the chassis on each side.

In the travel position, the compartment frame and sub-frame are securely bolted together.