How to Keep Your Lorry Fit.-1V.

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

This Week we Devote our Attention to Instructions as Regards the Upkeep of the Well,known Garrett Steam Motor Wagon,

The general maintenance of a steam wagon may be divided up into engine care, boiler care, and transmission care, including in the last and third item the road wheels.

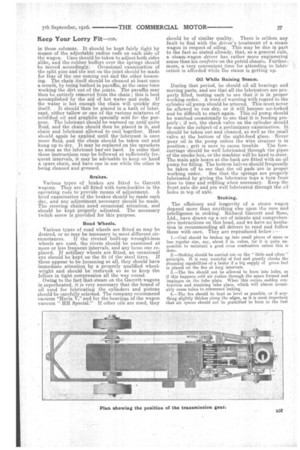

The Garrett steam wagon is almost too well known to need any preliminary reference to its construction. The engine is of what is commonly described as the " overtype," being carried on brackets above the boiler ; the transmission is by means of a two-speed gear, and then by chain in the usual manner to differential gear on the back axle. The outstanding; feature of the Garrett, and one which has a tendency towards economical working in respect of fuel consumption, is the superheater, which is standard on these machines.

As a general rule, the driver of a steam wagon has a little more engineering training, or has rather more mechanical aptitude than the average petrol-lorry driver. It is on that account, perhaps, not so necessary for us to deal so much in detail with the care of the steam wagon as has been thought advisable with the more popular type chassis. , The Engine.

With regard to the engine, the following are the points which require Occasional attention. Some of them, as, for instance, the glands and the joints in the steam pipe, give immediate notice when they are in need of attention, owing to the fact that a small amount of steam visibly escapes. It is necessary when tightening the glands to screw both nuts to the same degree of tightness and take care that the gland is kept square. The same remark applies to the joints of the steam pipe ; furthermore, whenever one of these has been renewed, the nuts should be tightened up occasionally for a day or so.

Immediate attention should be given to any of the bearings when the slightest knock is heard, and at, the same time care should be taken not to adjust them until too tight, It is recommended that the piston rings should be taken out and cleaned from time to time. Whenever it is necessary to remove the piston valves, care should be taken that the setting is not altered; a special gauge is provided for use when re placing them, and instructions for its use are supplied by the makers.

Minute instructions are given by the company as concerning the care of the boiler and superheater. We reproduce these in full, as they are particularly important..

Care•of the Boiler.

The boiler should be washed out every week (most important). The tubes must be brushed out at least once a day and always before lighting fire, and firebox must be kept clean and all scale removed. A manhole is provided inside the boiler barrel and mudholes in corners of firebox and smokebox tube plate for washing out. A powerful force pump is recommended for washing out the boiler. The firebox crown and outside of the tubes can be cleaned through the manhole and should be done about every three months, or more frequently if bad water has to be used. _ Do not blow off the boiler under pressure and never while there is a fire in the furnace. Let the boiler cool down before emptying. Caulk any leak as soon as it shows itself. Leaky .tubes can be remedied by using the -tube expander in a proper manner. This should be done as soon as possible after the leak is discovered. If a tube bursts, plug up each end until. .a new tube can be put in, It is advisable tO remora the lagging once a year, to clean the plates thoroughly and to paint them on the outside.

Never fill the boiler with cold water whilst hot.

Superheater.

Shut off the superheater and open drain cock every night to prevent condensed water collecting there. Blow out after steam is up and before starting engine. Clean off all soot between the coils of the superheater every night. This will be necessary more frequently when using inferior coal. With regard to transmission, the actual change speed gear needs no further attention beyond that already noted with respect to the bearings. Richard Garrett and Sons, Ltd. suggests the same treatment for the driving chain that we have frequently advised

in these columns It should be kept fairly tight by means of the adjustable radius rods on each side of the wagon. Care should be taken to adjust both sides alike, and the rubber buffers over the springs should he moved accordingly. Occasional examination of the split pins and the nut on the joint should be made for fear of the one coming out and the other loosening. The chain itself should be cleaned at least once a month, by being bathed in paraffin, at the same time working the dirt out of the joints. The paraffin may then be entirely removed from the chain ; this is best accomplished by the aid of hot water and soda. if the water is hot enough the chain will quickly dry itself. It should then be placed in a, bath of lubricant, either tallow or one of the various mixtures of solidified oil and graphite specially sold for the purpose. The lubricant should be warmed up until quite fluid,, and the chain should then be placed in it, and chain and lubricant allowed to cool together. Heat should again be applied until the .lubricant is once more fluid, and the chain should be taken out and hung up to dry. It may be replaced on the sprockets as soon as the lubricant has set hard. In order that these instructions may be followed at sufficiently frequent intervals, it may be advisable to keep on hand a spare chain, and have one in use while the other is being cleaned and greased.

Brakes.

Various types of brakes are fitted to Garrett wagons. They are all fitted with turn-buckles in the operating rods to provide means of adjustment. A brief examination of the brakes should be made each day, and any adjustment necessary should be made. The steering chains need occasional attention, and should be kept properly adjusted. The necessary twitch screw is provided for this purpose.

Road Wheels.

Various types of road wheels are fitted as may be desired, or as may be necessary to meet different cir

cumstances. If the riveted built-up wrought-iron wheels are used, the rivets should be examined at more or less frequent intervals, and any loose one replaced. If artillery wheels are fitted, an occasional eye should be kept on the fit of the steel tires. If these appear to be loosening at all, they should have immediate attention by a properly qualified wheelwright and should be reshrunk so as to keep the felloes in tight compression all the way round. Owing to the fact that steam on the Garrett wagons is superheated, it is very necessary that the brand of oil used for lubricating the cylinders and pistons should be carefully selected. The company recommend vacuum "Hecla V," and for the bearings of the wagon vacuum " HH Special." If other oils are used, they

should be of similar quality. There is seldom any fault to find with the driver's treatment of a steam wagon in respect of oiling. This may be due in part to the fact as stated already, that, as a general rule, a steam-wagon driver has rather more engineering sense than his confrere on the petrol chassis. Furthermore, a very convenient time for attending to lubrication is afforded while the steam is getting up.

Oil While Raising Steam.

During that period, he should oil all bearings and moving parts, and see that all the lubricators are properly filled, testing each to see that it is in proper working order. A word of warning with regard to the cylinder oil pump should be uttered. This must never be allowed to run dry, or it will become air-locked and be difficult to start again. This oil pump should be watched occasionally to see that it is feeding properly if not, the check valve on the cylinder should be made the subject of a preliminary examination. It should be taken out and cleaned, as well as the small valve at the bottom of the sight-feed glass. Never pour oil in the pump unless the wire strainer is in position ; grit is sure to cause trouble. The forecarriage should be well lubricated through the pipes of the smoke box, or the machine will be hard to steer. The main axle boxes at the back are fitted with an oil pump for filling. The bottom halves should frequently be taken off to see that the oil pads are in proper working order. See that the springs are properly lubricated by giving the lubricator tops a turn from time to time and refilling when necessary. Keep the front axle die and pin well lubricated through the oil holes in top of axle.

Stoking.

The efficiency and longevity of a steam wagon depend more than anything else upon the care and intelligence in stoking. Richard Garrett and Sons, Ltd.,. have drawn up a set of minute and comprehensive instructions on this head, and we have no hesitation in recoimnending all drivers to read and follow these with care. They are reproduced below :— 1.—Coal should be broken up into small pieces of more or

i less regular size, say, about 3 n. cubes, for it is quite impossible to maintain a good even combustion unless this is done.

2.—Stoking should be carried out on the "little and often " principle. It is very wasteful of fuel and greatly checks the steaming capabilities of a boiler if a, big supply of green fuel is plao.ed on the fire at long intervals.

3.—The fire should not be allowed to burn into holes, as if this happens cold air rushes through the space formed and impinges on the tube plate. When this occurs sudden contraction and straining take place, which will almost invariably cause tubes to commence leaking.

4.—The fire should be kept as level as possible, or if anything slightly thicker along the edges, as it is most important that air spaces should not be permitted to form in the fuel along the sides of the grate. This applies in particular to the edge of the grate nearest to the tube plate, as it is very essential that cold air should not be allowed to find its way in at this point which is immediately below the lowest tubes. 6.--A driver should try to fire as methodically as possible, and we suggest the following scheme for placing fuel on the grate, which will be found serviceable although it cannot always be rigidly followed:— 1.—Front right-hand corner. 3.—Back left-hand corner. 2.—Front left-hand corner, 4,—Back right-hand corner. By following some such method the whole surface of the fire grate will never be black, but parts will always be incandescent and at the same time regularly supplied with fuel.

6.—If possible arrange so as not to fire while pulling hard up a hill as the draught then is very fierce and a great volume of cold air is drawn through the open door, which is likely to start tubes leaking. This is quite easy to arrange when the wagon is travelling along a known road,

7.—Under no circumstances should the furnace doer be allowed to stand open more than is absolutely necessary. 8.—When clinkering the fire, the furnace door must necessarily be kept open. We also find it advisable to keep the ashpan door open as well because the air coming through the latter is slightly warmed by passing through the fire. It therefore, on meeting the air entering through the furnace door, mingles with it, heats it, and at the same time prevents its impinging directly on the tube plate. 9.—Keep the pressure up to the red line on gauge. Work the damper on ashpan according to bow the boiler steams. The exhaust ferrule in blast. pipe and the fire-grate should be adjusted to suit running conditions, special fuels, etc. As a general principle, always and everywhere keep

all nuts tight, and moving parts well oiled. If a split pin is found to be missing, replace it immediately. Keep the wagon clean. The cause of any knocking or squeaking should be immediately discovered, and removed by adjustment or ailing.