Where are the brake conversion kits?

Page 58

Page 59

Page 60

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

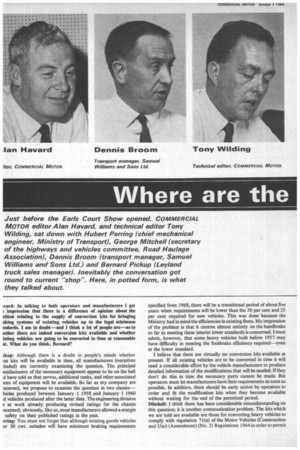

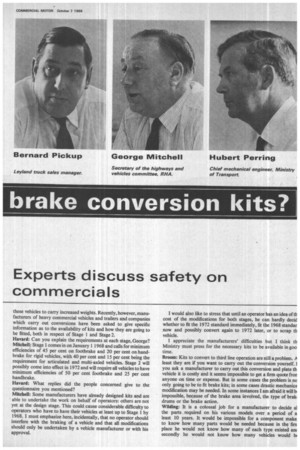

Just before the Earls Court Show opened, COMMERCIAL MOTOR editor Alan Havard, and technical editor Tony Wilding, sat down with Hubert Perring (chief mechanical engineer, Ministry of Transport), George Mitchell (secretary of the highways and vehicles committee, Road Haulage Association), Dennis Broom (transport manager, Samuel Williams and Sons Ltd.) and Bernard Pickup (Leyland truck sales manager). Inevitably the conversation got round to current "'shop". Here, in potted form, is what they talked about.

Experts discuss safety on commercials

ward: In talking to both operators and manufacturers I get 3 impression that there is a difference of opinion about the sition relating to the supply of conversion kits for bringing liking systems of existing vehicles up to the legal minimum mdards. I am in doubt—and I think a lot of people are—as to 'ether there are indeed conversion kits available and whether isting vehicles are going to be converted in time at reasonable St. What do you think, Bernard?

zkup: Although there is a doubt in people's minds whether .tse kits will be available in time, all manufacturers (ourselves ;luded) are currently examining the question. The principal mufacturers of the necessary equipment appear to be on the ball d have told us that servos, additional tanks, and other associated .ces of equipment will be available. So far as my company are ncerned, we propose to examine the question in two classes— hides produced between January 1 1958 and January 1 1960 d vehicles produced after the latter date. The engineering division e at work already producing revised ratings for the chassis .ncemed; obviously, like us, most manufacturers allowed a margin safety on their published ratings in the past.

Tring: You must not forget that although existing goods vehicles er 30 cwt. unladen will have minimum braking requirements

specified from 1968, there will be a transitional period of about five years when requirements will be lower than the 50 per cent and 25 per cent required for new vehicles. This was done because the Ministry had in mind the efficiencies in existing fleets. My impression of the problem is that it centres almost entirely on the handbrake so far as meeting these interim lower standards is concerned. I must admit, however, that some heavy vehicles built before 1957 may have difficulty in meeting the footbrake efficiency required—even at the lower standard.

I believe that there are virtually no conversion kits available at present. If all existing vehicles are to be converted in time it will need a considerable effort by the vehicle manufacturers to produce detailed information of the modifications that will be needed. If they don't do this in time the necessary parts cannot be made. But operators must let manufacturers have their requirements as soon as possible. In addition, there should be early action by operators to order and fit the modification kits when they become available without waiting for the end of the permitted period.

Mitchell: I think there has been considerable misunderstanding on this question; it is another communication problem. The kits which we are told are available are those for converting heavy vehicles to comply with regulation 71(a) of the Motor Vehicles (Construction and Use) (Amendment) (No. 2) Regulations 1964 in order to permit these vehicles to carry increased weights. Recently, however, manufacturers of heavy commercial vehicles and trailers and companies which carry out conversions have been asked to give specific information as to the availability of kits and how they are going to be fitted, both in respect of Stage 1 and Stage 2.

Havard: Can you explain the requirements at each stage, George? Mitchell: Stage I comes in on January 1 1968 and calls for minimum efficiencies of 45 per cent on footbrake and 20 per cent on handbrake for rigid vehicles, with 40 per cent and 15 per cent being the requirement for articulated and multi-axled vehicles. Stage 2 will possibly come into effect in 1972 and will require all vehicles to have minimum efficiencies of 50 per cent footbrake and 25 per cent handbrake.

Havard: What replies did the people concerned give to the questionnaire you mentioned?

Mitchell: Some manufacturers have already designed kits and are

• able to undertake the work on behalf of operators: others are not yet at the design stage. This could cause considerable difficulty to operators who have to have their vehicles at least up to Stage I by 1968. I must emphasize here, incidentally, that no operator should interfere with the braking of a vehicle and that all modifications should only be undertaken by a vehicle manufacturer or with his approval. I would also like to stress that until an operator has an idea of th cost of the modifications for both stages, he can hardly decid whether to fit the 1972 standard immediately, fit the 1968 standar now and possibly convert again to 1972 later, or to scrap th vehicle.

I appreciate the manufacturers' difficulties but I think th Ministry must press for the necessary kits to be available in goo time.

Broom: Kits to convert to third line operation are still a problem. A least they are if you want to carry out the conversion yourself.] you ask a manufacturer to carry out this conversion and plate th vehicle it is costly and it seems impossible to get a firm quote fron anyone on time or expense. But in some cases the problem is no only going to be to fit brake kits; in some cases drastic mechanics modification may be needed. In some instances I am afraid it will 1), impossible, because of the brake area involved, the type of braki drums or the brake action.

Wilding: It is a colossal job for a manufacturer to decide al the parts required on his various models over a period of a least 10 years. It would be impossible for a component make to know how many parts would be needed because in the firs place he would not know how many of each type existed an secondly he would not know how many vehicles would he :rapped when operators discovered the cost of a conversion. Many vehicles will have to be scrapped when the regulations :come effective because I can see that there will be occasions hen complete new braking systems will be needed and that mid cost between E700 and £1,000.

Eavard: It seems to me that we are all saying the same thing from ifferent viewpoints. The situation is confused and not universally gisfactory. I wonder what an operator who has to scrap a vehicle ill do if he cannot get an immediate replacement for it. I wish I ould believe that there was now no shortage of spare parts in eneral, quite apart from this question of brake conversion kits, but still hear operators complaining. Do you think there is still a hortage of some spares?

loom: The manufacturer appoints a distributor and I would have xpected him to insist on a certain capital outlay with regard to pares to follow up his sales force. But when the distributor sells :veral makes of vehicles and those of the cheaper ranges are ossibly more available, something has to suffer.

The spares situation is grim with some makes of vehicles. It ffects many operators who rim an efficient maintenance system. )f course, others who sit and wait for the GV9s to roil in wouldn't hink it much of a problem. As a company we employ an efficient lurchasing department who endeavour to locate any spares as and I/hen required, plus the operation of a stock control system to nsure an even flow of materials into the maintenance department. ievertheless, one has sometimes to resort to other means to obtain pares—I mean personal contacts with the man at the top. Once rou 'phone him, out come the spares.

'erring: There are at least six stages at which the supply of spare 'arts can be affected. First, the operator who doesn't maintain his rehicles properly and therefore doesn't call for many spares. iecondly, dealers may not place adequate orders in sufficient time vith their distributor. Thirdly, the distributor equally may not order n time from the manufacturer. Fourthly, you get the manufacturer icing misled by the first three factors and not, therefore, making adequate provision for the manufacture of spares either by his own factory or component suppliers. Fifthly, the manufacturer may be driven to robbing the spares supply in order to keep his production line going. And finally, the actual distribution of spares to the different outlets may not be as good as it could be.

The depressing thought is that at each of these six stages the most likely errors are those which will reduce the supply of spares. At every stage, too, there is the tendency for financial pressure to reduce the capital invested in stocks of spares.

Havard: It seems to make the whole system sensitive to errors. Perring: Yes, unreasonably seektive to errors at every stage. Wilding: It's a complex problem. There can be no doubt that some parts for all vehicles are difficult to obtain on the spot. In spite of vast amounts of capital being tied up by manufacturers in spares holdings there still appear to be shortages. In many cases the problem is in personnel and lack of communication. There are so many links in the chain between the operator and the manufacturer and any one of them can break down—and it is not always at the end where the part is or should be.

Mitchell: I agree with Tony; this really is a difficult problem. In many instances manufacturers say they have a "vehicle off the road" procedure but cases still occur where operators have to wait weeks and weeks for parts. Manufacturers don't seem to set aside spares for new vehicles soon enough. If a vehicle develops a fault which is a design one early in its life, affecting all the vehicles of a particular model, you get a crisis arising if there are not sufficient spares set aside.

There should be a minimum standard laid down by manufacturers to their agents for the stocking of spares and the times at which these facilities are available. I must admit in fairness that some manufacturers have gone out of their way to see to this. Another side of this problem is the tendency by distributors to order spares in bulk because they get a special discount for this type of order. This leads to an impossible position where operators are unable to get "bread and butter" parts for possibly three weeks because of this bulk order system.

If testing is going to begin in 1968 vehicle manufacturers should take a long hard look at the question of service and spare facilities. I don't agree with anyone who says he cannot control his agents; it's an excuse which cannot be accepted. In passing, I should like to mention how well I think this matter has been dealt with by Ford. Havard: Bernard, you've heard what the others have had to say. What do you think?

Pickup: The criticisms levelled at manufacturers, particularly regarding the supply of spare parts, has been highlighted during the past two or three years by the increased activity from the Ministry of Transport. Slow-moving parts which had previously not been scheduled in volume have been called up: things like spring hanger brackets and other chassis ironmongery have become defective through age and are enough to put a vehicle off the road.

Obviously manufacturers can only cater for spare parts from month to month, depending on the off-take of a spare part in the preceding months. If a sudden call is made it is not unreasonable to expect a slight delay to obtain, particularly on obsolete or nonproduction models. If a machine is in production, Leyland companies have a special system whereby the part can be taken direct from the production line—subject, of course, to this not causing a major breakdown or hold-up in production.

Havard: I don't think there is any doubt that individual manufacturers realize this problem and do what they consider to be enough to solve it. On the other band, one does still come across quite a lot of complaints. I agree that there are so many links between the manufacturer and the operator that any weak one can completely disrupt the chain, but I also get the impression that operators sometimes contact either the wrong man or fail to take their ease high enough. Perhaps more operators should refuse to take "no" for an answer and dump the whole thing in the lap of the appropriate sales manager—who will usually get things done.

Do you think enough attention is paid at the design stage of both vehicles and components to the safety factor?

Wilding: No. But I suppose design must always be a compromise with sales. The purchaser of a vehicle is always largely responsible for the situation. If he wants absolute safety built into design he could get it because manufacturers spend a lot of money on research. But it has been concentrated mainly on performance, economy and cabs since these are the matters upon which operators have been most vocal. I think you must remember the driver when talking about safety; no matter what is done in vehicle design, drivers often run their vehicles to the limits. If you improve the brakes some drivers will simply go faster and closer to the vehicle in front. Perring: I think designers have been very conscious of the need to include a good safety factor. But there have been quite a number of blind spots. The most obvious has been the very poor secondary brake performance which a number of designers have accepted, and the way in which some designers have been satisfied with a service brake which operates perfectly well at the ordinarily-used decelerations of the order of 0.2 or 0.3 g but which behave in an alarming fashion when applied fully.

Mitchell: I think this will be dealt with in time by the type testing scheme. In this respect I would like to draw attention to the mass of pipes and plastics tubing at the rear of heavy tractive units for the operation of the three-line air brake system. There is a profusion of reducing, non-return, and by-pass valves and many feet of tubing which will be a constant problem from the maintenance point view. It will also create many difficulties in tracing faults in ti braking system.

Broom: While manufacturers continue to build to a price du cannot give enough thought to safety. There is not enough con petition between component makers; they all think that what tht produce is the best. So long as it lasts out the guarantee period, tl attitude towards failed parts sometimes seems to be "I care not f( your predicament, Jack". As always, the operator pays. Pickup: The answer to your question, Alan, must be that in the pa insufficient attention has been paid to safety in the design stag But it must be remembered that vehicles are built at a commercial] economic price. It is easy to over-design and therefore over-cost vehicle. This has probably been the reason for so many manufa■ turers retiring from the vehicle field.

Havard: From what you say, this is another case of "you get win you pay for". Personally, I would have thought that most vehicle on the road today are as safe as they need to be in normal operatim despite what our worthy Minister of Transport implies in publi whenever she gets the chance.

Take just four items: brakes; cabs; headboards; and tyre! Which is the most important influence on safety in design?

Perrin: Brakes. The four features you have chosen all affect th avoiding of accidents caused by the vehicle's own motiot Therefore, brakes to reduce the speed of the vehicle to rest must b considered the most important.

Broom: All the four items leave a lot to be desired where safety i concerned. My choice is cab design. Most operators would prefe an all-metal cab from a maintenance point of view. Large screen are nice to look at and give good forward vision; but can the drive see well all around? Why can't we have standard instrumentation— particularly with regard to positioning? What about a brake pressur warning device that comes on before it's too late? How abou attention to ventilation? And how about more attention to gettinl in and out?

Pickup: Brakes are most important. Then tyres, followed by cab an headboard. Mind you, we'd have more safety if there were correc weight distribution according to the manufacturer's recommen dations.

Mitchell: We've said an awful lot about brakes today, so I wil plump for cabs. It is so important for the driver to have good al round vision. This is a matter of considerable concern at tin moment in view of the design of certain cabs which do not permi the driver to open the window because, immediately this is done, al sorts of dirt and muck from the road are sucked into the cab. Tin: is a matter which should receive immediate attention.

Wilding: Brakes for me too. If a man can stop his vehicle adequatel3 in a short distance he can get out of most difficult situations. Tyre are obviously important—they affect braking and steering if the3 are below standard. So far as headboards are concerned, one has tc accept that it is impracticable to design one to withstand a loac under any conditions but they should be strong enough to hold tht load under normal heavy braking conditions. In the case of cabs you could design them much stronger, but would operators pay foi them?

Havard: Once again, we are back at this point of "will the operatoi pay?" While my logic agrees that improvements have to be paid for my sentiment leads me to ask why only the operator should pay