A Clever

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

Dust-trap Cover

for Refuse Vehicles

First-published Details of the F.M. Cover—One of the Best of its Kind that We Have Yet Seen

A S the outcome of long experience the sale of refuse-collection vehicles and the study of the needs of municipalities the well-known concern of distributors of Vulcan commercial motors for London and the Home Counties, Fitch, McGillivray and Co., Ltd., of 167 Shaftesbury Avenue, London, W.C.2, has patented and produced an ingenious type of treadle-operated cover for low-load ing refuse-collection vehicles. One of its main advantages is that, as the lid rises, its edge does not project beyond the side of the body, but at the first movement it recedes. By reason of this fact dust cannot be blown out by the closing of the lid and, as it "sits down" on the refuse it cannot strike the operator's head. There are no sliding surfaces to wear or clog and no working parts in contact with the refuse.

-Mr. Fitch and Mr. McGillivray have., shown us a Vulcan .35-40-cwt. low-loading chassis with this body. The loading height is 4 ft. 6 ins. from the ground, or about 4 ft. 1 in. from the average kerb, and the opening for each cover (of which there are three on each side) is 2 ft. 9 ins. wide and 2 ft. 1 in. from the bodyside to the lip of the cover.

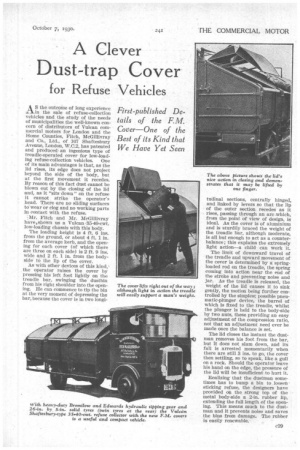

As with other devices of this kind,, the operator raises the cover by pressing his left foot lightly on the treadle bar, swinging the dustbin from his right shoulder into the opening. He can commence to tip the bin at the very moment of depressing the bar, because the cover is in two longi

tudinal sections, centrally hinged, and linked by levers so that the lip of the outer section recedes as it rises, passing through an arc which, from the point of view of design, is ideal. As the cover is of aluminium and is sturdily braced the weight of the treadle liar, although moderate, is all but enough to act as a counterbalance; this explains the extremely light action—a child can work it.

The limit of downward travel of the treadle and upward movement of the cover is determined by a springloaded rod on the treadle, the spring coming into action near the end of the stroke and preventing noise and jar. As the treadle is released, the weight of the lid causes it to sink gently, the motion being further controlled by the simplest possible pneumatic-plunger device, the barrel of which is fixed to the treadle, whilst the plunger Is held to the body-side by two nuts, these providing an easy adjustment of the compression ratio, not that an adjustment need ever be made once the balance is set.

The lid closes the instant the dustman removes his foot from the bar, but it does not slam down, and its fall is arrested momentarily when there are still 3 ins, to go, the cover then settling, so to speak, like a gull on a rock. Should the operator leave his hand on the edge, the pressure of the lid will be insufficient to hurt it.

Realizing that the dustman sometimes has to bump a bin to loosen sticking refuse, the designers have provided on the strong top of the metal body-side a 2-in, rubber lip, extending the full length of the opening. This means much to the dustman and it prevents noise and saves the bins from damage. The rubber is easily renewable.