Lubrication Tests of Ball Bearings.

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

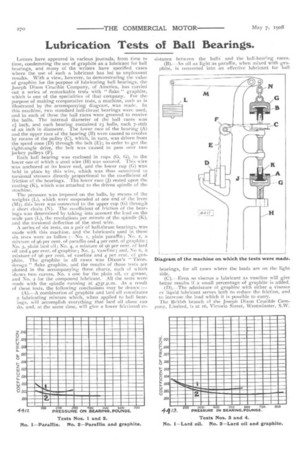

Letters have appeared in various journals, from time to time, condemning the use of graphite as a lubricant for ball bearings, and many of the writers have specified cases where the use of such a lubricant has led to unpleasant results. With a view, however, to demonstrating the value of graphite for the purpose of lubricating ball bearings, the Joseph Dixon Crucible Company, of America, has carried out •a series of remarkable tests with " flake " graphite, which is one of the specialities of that company. For the purpose of making comparative tests, a machine, such as is illustrated by the accompanying diagram, was made. In this machine, two standard ball-thrust bearings were used, and in each of these the ball races were grooved to receive the balls. The internal diameter of the ball races was 1,s5. inch, and each bearing contained 23 balls, each 7-16th of an inch in diameter. The lower race of the bearing (A) and the upper race of the bearing (B) were caused to revolve by means of the pulley (C), which, in turn, was driven from the speed cone (D) through the belt (E); in order to get the Tight-angle drive, the belt was caused to pass over two jockey pulleys (F). Each ball bearing was enclosed in cups (G, G), to the lower one of which a steel wire (H) was secured. This wire was anchored at its lower end, and the lower cup (G) was held in place by this wire, which was thus submitted to torsional stresses directly proportional to the co-efficient of friction of the bearings. The lower race (I) rested upon the casting (K), which was attached to the driven spindle of the machine.

The pressure was imposed on the balls, by means of the weights (L), which were suspended at one end of the lever (N1); this lever was connected to the upper cup (G) through a short chain (N). The co-efficient of friction of the bearings was determined by taking into account the load on the Scale pan (L.), the revolutions per minute of the spindle (K), and the torsional deflection of the steel wire.

A series of six tests, on a pair of ball-thrust bearings, was made with this machine, and the lubricants used in these six tests were as follow :—No. 1, plain paraffin; No. 2, a mixture of 96 per cent. of paraffin and 4 per cent. of graphite; No. 3, plain lard oil; No. 4, a mixture of 96 per cent, of lard oil and 4 per cent, of graphite ; No. 5, vaseline; and, No 6, a mixture of 96 per cent. of vaseline and 4 per cent. of graphite. The graphite in all cases was Dixon's " Ticonderoga " flake graphite, and the results of those tests are plotted in the accompanying three charts, each of which shows two curves, No. i one for the plain oil, or grease, and No. 2 for the compound lubricant. All the tests were made with the spindle running at 475r.p.m. As a result of these tests, the following conclusions may be drawn :—

(A).—A combination of graphite and lard oil constitutes

a lubricating mixture which, when .applied to ball bear

ings, will accomplish everything that lard oil alone can do, and, at the same time, will give a lower frictional re

sistance between the balls' and the ball-bearing races. (B).—An oil as light as paraffin, when mixed with graphite, i5 converted into an effective lubricant for ball

bearings, for all cases where the loads are on the light side.

(C).—Even so viscous a lubricant as vaseline will give better results if a small percentage of graphite is added.

( D ). —The admixture ot graphite with either a viscous or liquid lubricant serves both to reduce the friction, and to increase the load which it is possible to carry.

The British branch of the Joseph Dixon Crucible Company, Limited, is at 26, Victoria Street, Westminster, S.W.