TECHNOLOGY OPE SMALL DIESELS

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

Improving the fuel efficiency and decreasing the pollution of small diesels is a never-ending task. Direct injection is seen as the way forward. Diesel engines are the norm for 'serious' intensive-use operation, even in the smallest car-derived vans like the Ford Fiesta. The recent introduction of an Italian Lombardini diesel option in the Daihatsu Hi-Jet microvan only underlines the point

But making diesels even more fuel efficient and les..s polluting is a never-ending task. In diesels of less than about 750cc per cylinder the pre-combustion chamber indirect-injection (idi) was for many years the norm.

While direct-injection (di) is seen as the way forward because of the consumption implication, getting them to work in higher-revving engines is a problem.

In simple terms, the fire has to be lit, extinguished and relit up to 30 times a second. Work on the combustion chambers, ports and on injector spray patterns allowed Ford to introduce the first successful small direct injection engine (the now-ubiquitous 2,5di) in the Transit. Volkswagen and Perkins followed with even smaller cylinder sizes.

Ford's efforts brought a 10 to 15% fuel economy bonus which may be one reason for Transit's domination in the UK.

DI competition is now coming from the 2.5litre Sofim engine in the Fiat Ducato, Renault Master and the Iveco Daily range. Mercedes has also gone for direct injection on its turbocharged 2.9-litre five-cylinder for top-of-therange Sprinters.

Volkswagen's Sprinter lookalike' replacement for the LT, due for launch in May, will be powered throughout by turbo-interccioled di diesels. Unusually the lighter versions will have a five-cylinder 2.5-litre Audi TDi engine. Heavier models will have four-cylinder, allnew, 130bhp 2.8-litre engine developed and manufactured in South America by M17v'M.

But there are down sides to di engines: they are noisier and produce more oxides of nitrogen (NOx) than their idi counterparts.

Emissions legislation

European law-makers in Brussels, in framing emissions legislation for light commercial vehicles (up to 3.5 tonnes), have acknowledged the difficulties in reducing emissions in general, and NOx in particular, from di diesels.

Instead of coming into line with Euro-2, there is a proposed three-year derogation on the laid-down limits for NOx, hydrocarbons and particulates.

In any case, the light vehicle category is divided into three weight segments: up to 1250kg gvw; 1250 to 1700kg: and 1700 to 3500kg; with progressively more lenient emission limits being applied up the weight range. This is because a given engine will have to work harder in heavier vehicles and so produce more emissions as the limits are specified in grammes per kilometre.

Why the concession of a three-year derogation for di diesels specifically? The answer is that the EUs environmental concerns extend beyond the emissions.

The di's unrivalled fuel economy not only stretches the earth's finite fossil fuel resources, it brings a directly fuel consumption-related reduction in the amount of carbon dioxide released by the vehicle — helping to put a brake on global warming.

Nearly all manufacturers are engaged in di technology for small diesels. Many use outside research organisations with expertise in detailed analysis of the combustion process. Controlling the way the fuel-air mixture burns is bound up with the mixing itself which is largely dictated by the injection system.

Being able to regulate the initial fuelling rate is key to meeting the noise and NOx challenge for small diesels. With the widespread application of electronics to control diesel fuel systems, injection rate 'shaping' becomes feasible.

Steyr Motorentechnik in Austria (now owned by Daewoo) is working on multistage unit-injector nozzle systems for small di diesels.

Nozzle pressures up to 1,700bar, with accompanying fuel consumption and particulate reduction advantages, are now achievable, says Steyr. However, this can further exacerbate noise and stimulate NOx formation.

Steyr's two-stage nozzle design, already running in experimental engines, allows fuel to be injected initially through partiallyobstructed nozzle spray holes which are, later in the cycle, fully uncovered. Concentric needles (plungers), moving one relative to the other, regulate orifice size and spray rate. A 'throttling' effect between the needle and orifice entrance simultaneously controls the spray pattern.

Spray holes

Steyr is now working on a three-stage nozzle, the additional stage utilising a second set of three spray holes (making six in all). Two coil springs in the top of the injector determine first and second stage pressure limits, interacting with electronically controlled, solenoid-actuated needle movements.

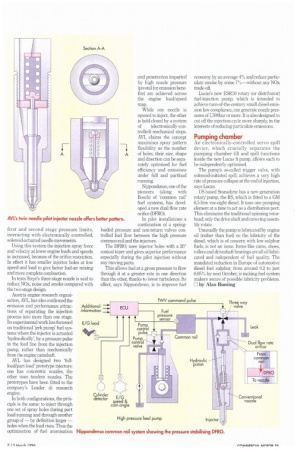

Using this system the injection spray force and velocity at lower engine loads and speeds is increased, because of the orifice restriction. In effect it has smaller injector holes at low speed and load to give better fuel-air mixing and more complete combustion.

In tests Steyr's three-stage nozzle is said to reduce NOx, noise and smoke compared with the two-stage design.

Austria engine research organisation, AVL, has also confirmed the emission and performance attractions of separating the injection process into more than one stage. Its experimental work has focussed on traditional 'jerk pump' fuel systems where the injector is actuated 'hydraulically', by a pressure pulse in the feed line from the injection pump. rather than mechanically from the engine camshaft.

AVL has designed two 'fullload/part-load' prototype injectors: one has concentric nozzles, the other uses tandem nozzles. The prototypes have been fitted to the company's Leader di research engine.

In both configurations, the principle is the same: to inject through one set of spray holes during part load running and through another group of — by definition larger — holes when the load rises Thus the optimisation of fuel atomisation and penetration imparted by high nozzle pressure (pivotal for emission benefits) are achieved across the engine load/speed map.

While one needle is opened to inject, the other is held dosed by a system

of (electronically-controlled) mechanical stops. AVL claims the concept maximises spray pattern flexibility as the number of holes, their size, shape and direction can be separately optimised for fuel efficiency and emissions under full and partload running.

Nippondenso, one of the pioneers (along with Bosch) of 'common rail' fuel systems, has developed a new dual flow rate orifice (DFRO).

better pattern. In pilot installations a combination of a springloaded pressure and non-return valves controlled fuel flow between the high pressure common rail and the injectors.

The DFRO, uses injector holes with a 20° conical taper and gives superior performance especially during the pilot injection without any moving parts.

This allows fuel at a given pressure to flow through it at a greater rate in one direction than the other, thanks to lower turbulence. Its effect, says Nippondenso, is to improve fuel economy by an average 4% and reduce particulate smoke by some 7%—without any NOx trade-off.

Lucas's new ESR10 rotary (or distributor) fuel-injection pump, which is intended to achieve turn-of-the-century small diesel emission law compliance, can generate nozzle pressures of 1,500bar or more. It is also designed to cut off the injection cycle more sharply, in the interests of reducing particulate emissions.

Pumping chamber

An electronically-controlled servo spill device, which crucially separates the pumping chamber fill and spill functions inside the new Lucas fi pump, allows each to be independently optimised.

The pump's so-called trigger valve, with solenoid-initiated spill, achieves a very high rate of pressure collapse at the end of injection, says Lucas.

US-based Stanadyne has a new-generation rotary pump, the RS, which is fitted to a GM 6.5-litre vee-eight diesel. It uses one pumping element at a time to act as a distribution port. This eliminates the traditional spinning rotorhead; only the drive shaft and cam-ring assembly rotate.

Unusually the pump is lubricated by engine oil (rather than fuel) so the lubricity of the diesel, which is of concern with low-sulphur fuels, is not an issue. Items like cams, shoes, rollers and driveshaft bearings are all oil lubricated and independent of fuel quality: The mandated reduction in Europe of automotive diesel fuel sulphur, from around 0.2 to just 0.05% by next October, is making fuel system makers aware of possible lubricity problems. O by Alan Bunting