The New Hans Renold Patent Silent Chain.

Page 5

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Constructional Details.

No company has done more towards perfecting the details of transmission chains than Hans RenoId, Limited, of Progress Works, Manchester. As a maker of roller and "silent" cnains, the company has built up for itself a reputation all over the world by the excellence of its products. Our illustrations show the latest form of patented, silent chain, which, as will be seen, is furnished with hardened, segmental, steel, removable bushes. In the earlier types of similar chains, produced by the same maker, the plates were simply drilled for the reception of a steel pivot. It was, sometimes, found that, if the driving and driven sprockets were slightly out of line, the tendency to bend the chain made the edges of the plates cut into the pivotal pins, or rivets, and cause both to wear out in a relatively short space of time.

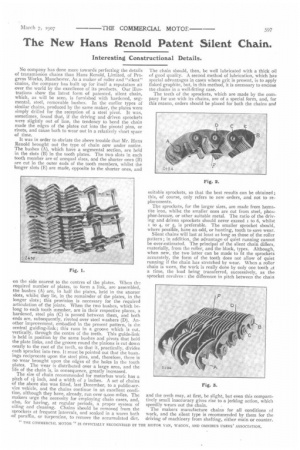

It was in order to obviate the above trouble that Mr. Hans Renold brought out the type of chain now under notice. The bushes (A), which have a segmental section, are held in the slots (B) in the tooth plates. The two slots in each tooth member are of unequal sizes, and the shorter ones (13) are cut in the outer ends of the tooth members, whilst the longer slots (E) are made, opposite to the shorter ones, and

on the side nearest to the centres of the plates. When thc required number of plates, to form a link, are assembled, the bushes (A) are, in half the plates, held in the shorter slots, whilst they lie, in the remainder of the plates, in the longer slots; this provision is necessary for the required articulation of the joints. When the two bushes, which belong to each tooth member, are in their respective places, a hardened, steel pin (C) is passed between them, and both ends are, subsequently, riveted over steel washers (D). Another improvement, embodied in the present pattern, is the central guiding-link ; this runs in a groove which is cut, vertically, through the centre of the teeth. This guide-link is held in position by the same bushes and pivots that hold the plate links, and the groove round the pinions is cut down nearly to the root of the teeth, so that it, practically, divides each sprocket into two. It must be pointed out that the bushings reciprocate upon the steel pins, and, therefore, there is no wear brought upon the edges of the holes in the tooth plates. The wear is distributed over a large area, and the life of the chain is, in consequence, greatly increased. The size of chain recommended for motorbus work has a pitch of ti inch, and a width of 2 inches. A set of chains of the above size was fitted, last December, to a public-service vehicle, and the chains continue in an excellent condition, although they have, already, run over 9,o0o miles. The makers urge the necessity for employing chain cases, and, also, for having, at regular periods, a proper system of oiling and cleaning. Chains should be removed from the sprockets at frequent intervals, and soaked in a worm bath of paraffin, or turpentine, to remove the accumulated dirt.

The chain should, then, be well lubricated with a thick oil of good quality. A second method of lubrication, which has special advantages in cases where grit is present, is to apply flaked graphite, but, in this method, it is necessary to enclose the chains in a well-fitting case.

The teeth of the sprockets, which are made by the company for use with its chains, are of a special form, and, for this reason, orders should be placed for both the chains and suitable sprockets, so that the best results can be obtained ; this, of course, only refers to new orders, and not to replacements. The sprockets, for the larger sizes, are made from hematite iron, whilst the smaller ones are cut from steel, phosphor-bronze, or other suitable metal. The ratio of the driving and driven sprockets should never exceed i to 6, whilst to 4, or 5, is preferable. The smaller sprocket should, where possible, have an odd, or hunting, tooth to save wear. Silent chains will last at least as long as those of the roller pattern ; in addition, the advantage of quiet running cannot be over-estimated. The principal of the silent chain differs, materially, from the roller, and the block, types. Although, when new, the two latter can be made to fit the sprockets accurately, the form of the tooth does not allow of quiet running if the chain has stretched by wear. When a roller chain is worn, the work is really done by only one tooth at a time, the load being transferred, successively, as the sprocket revolves : the difference in pitch between the chain and the teeth may, at first, be slight, but even this comparatively small inaccuracy gives rise to a jerking action, which speedily wears out the chain. The makers manufacture chains for all conditions of work, and the silent type is recommended by them for the driving of machinery from shafting, either main or counter.