Robey and Co., Limited.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Exhibit: One 5-ton Wagon : one 5-ton Tractor.

On this stand will be found two excellent examples of present-day design and workmanship as applied to a steam wagon and a tractor. One point specially worthy of notice in the former is the thorough manner in which all the moving parts of the machinery are enclosed. Not only are all the usual parts, such as the engioe motion and changespeed gears, enclosed, but, also, the radius-rod joints and the axle bearings, the result being that not a single nilcup is to be found, and the driver has no necessity to use an oil-can, except for the parts immediately beneath the footplate_

The boiler fitted to the wagon is of the vertical fire-tube type, and the uppei ends of the tubes are always below the water level. An exhaust-steam superheater is placed at the bottom of the chimney, which is capable of being swung over when the tubes require cleaning. Six large mud-hoe deors are furnished, so that efficient washing of the boiler is rendered an easy matter. The total heating surface of the boiler is about 70 square feet, and the area ot

the fire-grate is 3 square feet. The working pressure is 200 pounds on the souare inch.

The engine is of the horizontal com pound type, with one cylinder on each side, and the normal running speed is 380 revolutions per minute. The two gear ratios are 21 and 6 miles per hour, but a greater speed can easily be maintained if necessary. Reversing of the engine direction is obtained by a gear, which has a sliding wedge-motion, attached to the crankshaft.

Two large covers are fitted, one on each side of the transmission casing, and, when these are removed, a clear view is obtained of the internal mechanism. Sliding inspection doors are, also, placed on the top of the casing further to facilitate running adjustments. Two steel pinions are keyed to the crankshaft, which has two equalising discs on it inside the casing, and these pinions are in permanent mesh with two spur wheels loose on the intermediate shaft. A dog-clutch slides on this shaft, being placed between the two wheels, and either ratio of gear can thus be engaged at will. The intermediate shaft is in two portions; ti,(.% major length is that to the near side of the vehicle, and this part is supported in brackets from the centre cross-member of the frame, and carries the two loose spur-wheels and the dog-clutch. The short portion

of the shaft depends from a separate bracket and only has upon it a wide cutsteel pinion, which gears into a cut gear-ring bolted to the cage of the differential on the live back axle. Platetype couplings are fitted to the inner adjacent ends of the Separate portions of the intermediate shaft to allow for play on rough surfaces.

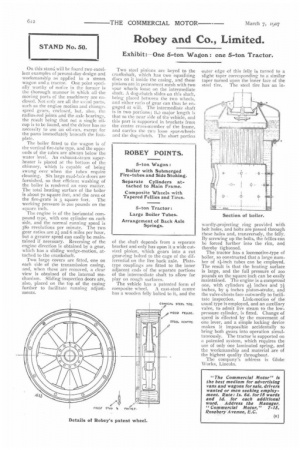

The vehicle has a patented form of composite wheel. A cast-steel centre has a wooden Icily bolted to it, and the outer edge of this telly is turned to a slight taper corresponding to a similar taper turned upon the inner face of the

steel tire. The steel tire has an in wardly-projecting ring provided with bolt holes, and bolts are passed through these holes and, transversely, the telly. By screwing up the bolts, the follies can be forced further into the rim, and thereby tightened. The tractor has a locomotive-type of boiler, so constructed that a large number of t1-inch tubes can be employed. The result is that the heating surface is large, and the full pressure of zoo pounds on the square inch can be easily maintained. The engine is a compound

one, with cylinders inches and 7i inches, by 9 inches piston-stroke, and the valve-chests face outwardly to facili tate inspection. Link-motion of the usual type is employed, and an auxiliary valve, to admit live steam to the lowpressure cylinder, is fitted. Change of speed is effected by the movement of one lever, and a simple locking device makes it impossible accidentally to bring both gears into operation simultaneously. The tractor is supported on a patented system, which requires the use of only one laminated spring, and the workmanship and material are of the highest quality throughout.

The company's address is Globe Works, Lincoln.