New Trader is as Good as it Looks

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

By Joint F. Moon, A.M.I.R.T.E.

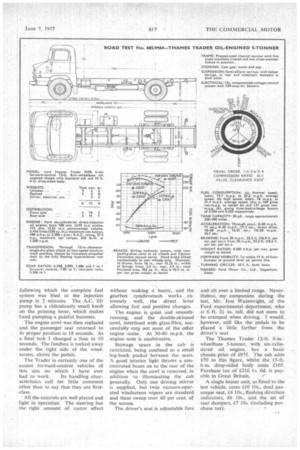

THE new Ford Thames Trader range, described in The Commercial Motor on May 24, has caused a .minor revolution in the commercial-vehicle industry, with its simple, sturdy design, high power and safe and comfortable cab. A test of a 5-ton oil-engined chassis has shown it to be an outstanding vehicle.

High power to weight gives an unrivalled road performance, and drivers will find that few main-road hills will demand the use of even second gear. The engine is large by normal 5-tanner standards, but this does not result in a heavy, fuelconsumption rate, 19.7 m.p.g. being returned at 27.2 m.p.h. average speed. Moreover, a long life can be expected from the unit, because it will rarely be worked to its maximum.

Pleasant to Handle The Trader is an extremely: likeable vehicle to drive, with its excel. lent forward visibility, light controls and comfortable and well-finished cab. Its appearance is distinctive, attractive and thoroughly practical, and adequate insulation and ventilation make it quiet and cool to drive.

A 12-ft. 8-in.-wheelbase oilengined chassis was provided for the test, complete with standard cab and 15-ft. 6-in, drop-sided body. The only non-standard items were rear dampers, dual passenger seat, flashing direction indicators and single fresh-air heater unit, these being available as optional extras.

Iron weights, evenly distributed in the body, formed the test load, and the vehicle was run at a gross weight of 8 tons 11 cwt. A reasonable weight distribution ratio was achieved, the front-axle loading being just under 3 tons.

Starting from North London, the c.10 Trader was driven out to Luton for tests over circuits which are used for two other makes of medium-capacity vehicle. During the journey to Luton I was soon able to appreciate the high power output of the engine, because, despite a relatively, high rear-axle ratio of 5.286 to 1, gear changes were seldom necessary.

In fact, other than when starting from a standstill, the only time I had to use second gear was during the ascent of Muswell Hill, where it became necessary . to engage • this ratio to breast the 1 in 8.6 section. .

The " glasshouse " vision provided by the full-width one-piece windscreen gives complete confidence when driving in thick' traffic, and combines with the liveliness of the engine and the efficiency of the gearbox synchromesh mechanism to make it easy to maintain a high average speed under such conditions. The 30 miles to Luton were covered in little over an hour without once exceeding 40 m.p.h.

Braking and acceleration tests were made on the main A6 road just south of Luton, the road surface being of asphalt. During the brake tests an average roaximum deceleration of 75 per cent. was recorded on the Tapley meter from each speed. Stopping distances from 20 m.p.h. and 30 m.p.h. were equivalent to 52 per cent., and 57.5 per cent., respec. tively, indicating slight servo lag.

Although the rear wheels were proportionately more lightly loaded than the front wheels, excessive weight transference did not take place, as indicated by the fact that none of the wheels skidded during these tests. The braking system was shown to be well balanced and close to the peak of efficiency for a vacuum-hydraulic • system.

Hand-brake tests from 20 m.p.h. produced average Tapley meter readings of 33 per cent., indicating that a good purchase can be obtained upon the lever, which is conveniently situated to the left of the driving seat.

For the standing-start acceleration tests it was necessary to use only second and third gears, the maximum speed in third being 31 m.p.h. The times obtained make the Trader the liveliest 5-tanner yet tested by The Cotnmercial Motor, and show the advantage of high engine power and a wise choice of gearbox ratios.

Satisfactory times were obtained from the direct-drive tests, but the figures reflect the high axle ratio. Nevertheless, the transmission was reasonably smooth when in top gear' at 10 m.p.h., and at this speed it was almost possible to hear the individual cylinder explosions!

The torque curve of the Ford 6D engine is not particularly flat by present-day standards, but a fairly consistent acceleration rate in direct drive is apparent.

A six-mile undulating consumption route between Barton and Clophill was used, this being an out-and

return course over .a narrow stretch of main road. A calibrated fuel test tank was employed.

. Two tests were conducted, the first run being at normal speed, during which 35 mph. was not exceeded. The course was covered at an average speed of 27.2 M.p.h., and the fuel-consumption rate was 19.7 m.p.g. This is an extremely good figure, particularly in view of the high power-toweight ratio.

A second fuel run was then made at full throttle, wherever possible, • , but the traffic had become thicker along the course since. the first run was completed and at no time • was it possible to exceed 45 m.p.h. Several minutes were spent in third gear following a large excavator.

Excessive use of the throttle increased the fuel-consumption rate to 16 m.p.g., whilst traffic delays caused the average speed to drop to 31.4 m.p.h. 'This test did at least show, however, that it would be rare for the consumption rate to exceed 16 m.p.g. with a 5-ton payload, however had the conditions.

Bison Hill, a finite climb with an average gradient of 1 in 101 and sections of up to 1 in 61, was used for the hill-climb and brake-fade tests. These tests were made in , an ambient temperature of 59° F., and before the climb the engine-coolant temperature was 170° F.

The ascent was made in the record time of 3 minutes 37 seconds, and bottom gear was required for 50 seconds, whilst second was used twice for a total time of 55 seconds. The coolant temperature rose to 188° F., indicating that for all home-market conditions the system (pressurized to 4 p.s.i.) is entirely adequate.

Export models have a four-bladed fan, instead of the two-bladed unit fitted to the test vehicle, so overheating should be rare even in tropical countries. With neutral engaged and the foot brake applied to restrict the speed to 20 m.p.h., a descent was then made. This occupied 2* minutes and the last 35 seconds were spent in top gear with full throttle applied to compensate for the reduced gradient. At the end of this test the drums were not smoking, but a full-pressure stop from 20 m.p.h. revealed that fade had occurred, the maximum efficiency having been reduced to 44 per cent

Bottom-gearRestart I then reduced to the 1-in-61 section, where a smooth part-throttle restart in bottom gear was made. While stationary, the hand brake held the vehicle comfortably, although the drums were very hot after the descent. At The top. of the hill, after this test, a second temperature check showed the coolant to be at 186° F.

A second descent was made in 21 minutes, but further fade had taken place, a stop from 20 m.p.h. producing only 24 per cent. efficiency as recorded by the Tapley meter. These two tests were extremely severe and the fade recorded, although serious at face value, is no worse than on the other vehicles of this size which I have taken down this hill.

The test lorry had woven brake facings, which naturally do not stand up to fade as well as moulded units. Under normal conditions a hill of this nature would never be descended in neutral and full use would be made of engine braking effort.

The Trader was then taken to the workshops of the Luton Motor Co., Ltd., where it had been arranged with Mr. D. Malone, service manager, that space should be found for me to conduct a series of maintenance tests.

Poor Tool Kit

Inspection of the standard tool kit revealed that this would be of little use to me for maintenance, as it consists solely of a Lake and Elliot 4-ton hydraulic jack, jack handle, starting handle, wheelbrace and a combined tornmy bar and wheel-rim lever. • An unusual feature of the Ford cab design is the small bonnet incorporated in the front panel. This takes 7 seconds to raise, and, with it lifted, was able to check the water level in 6 seconds, the engine-oil level in 18 seconds, the air-filter oil level in 45 seconds, and the engine breather filter oil level in 10 'seconds.

This grouping of the items which require frequent checking was a great time-saver. The bonnet, which e I 2 has a hinged prop, takes 5 seconds to close.

I was particularly pleased to see that the air cleaner is well exposed and easy to dismantle. A single through-bolt with large winged head not only fastens the filter top but also secures the whole filter to its pedestal on the engine cylinder block. The filter is clipped to a long rubber hose, which allows the top to be swung aside, whereupon either the element or the complete filter body can easily be lifted.

There is a cortibined filler and level plug in the right side of the gearbox, with a drain plug 4 in. below it. Both plugs fit a *-in. A.F. spanner and the gearbox oil level was checked in 25 seconds. Similarly, the reat-axle oil level was verified in 30 seconds, there being a combined filler and level plug in the rear of the -axle housing.

The two 6v. batteries are housed in a crate on the near-side side member, just behind the cab.. Two wing nuts, with self-locking plates under them, secure the battery lid, and are easy to remove. Because there is only 7 in. between the floor bottom and the tops of the batteries however, a mirror is necessary to check the levels, but the whole operation can be completed in just over 2 minutes.

• Spare-wheel Which

Just ahead of the near-side rear wheels is the spare-wheel winch-type mounting. The wheel is secured by two nuts and with these removed, it can be wound down without difficulty, the whole operation taking 11 minutes.

I then spent 13,minute in winding up the wheel again and 11 minutes in refitting the nuts. The simple winch works well, but is a little stiff to operate when winding up in the initial stages, because of the lerigth of the handle protruding from the frame.

A single fluid reservoir serves the brakeand clutch-actuating circuits. This reservoir is attached to the underside of the cab floor and its cap protrudes through the floor ' just behind the driving seat. By sliding the seat forward the cap can easily be reached and I checked the level in 20 seconds, including moving the seat and replacing it.

By placing the jack centrally under the front axle I was able to jack up both front wheels at once for brake adjustment. There are two external hexagonal adjusters per wheel, and the front brakes were adjusted in a total time of 24minutes, including jacking and lowering the -wheels.

Unfortunately, the hydraulic jack would not quite go under the differential pot, so the rear wheels could not be raised simultaneously. Jacking up each side of the axle and adjusting each brake (one squareheaded adjuster per wheel) took a total time of 5 minutes.

The insulated engine cowl inside the cab is secured by two rubber clips, but when a dual passenger seat is fitted, this has to be moved sideways before the bowl can be removed. This all takes only 13 seconds. however.

Injector Withdrawal

An attempt was then made to withdraw an injector. First this entailed removing the rocker cover, which is secured by 10 cheese-head screws, it being necessary to detach ti.e air cleaner to gain access to one of the screws. The cover took 51minutes to remove.

The next job was to take off the leak-back pipe, which runs across the top of all the injectors, a 44minute operation. It was then found that we had no spanners to fit the injector securing bolts, but had these spanners been available it should have been possible to remove each injector in little more than a minute.

Replacement of each injector Would occupy about the same time, and it took 44 minutes to refit the leak-back pipe and 8 minutes to replace the rocker cover.' Injector removal -is the only long-winded task associated with the engine, and one can only hope that the injectors do not need replacing frequently.

There is a removable plate in the lower section of the engine cowl at each side, and removal of the plate on the right gives access to the fuelinjection pump, the lift pump and the main fuel filter.

Two Captive Nuts

This plate is secured by four bolts, the two in the floor having captive nuts, but for some obscure reason the two in the side have loose nuts. The plate, therefore, takes nearly 24 minutes to remove and 24 minutes to put back.

With the plate removed, I stripped down the main fuel filter and took out the element in 2 minutes, whilst reassembly required a further

3 minutes. This filter is not particularly inaccessible, but the head Of the securing bolt lies very close tO the top of the exhauster and is a little difficult to turn.

From underneath the vehicle I removed, cleaned out and replaced the sediment bowl in half a minute. following which the complete fuel system was bled at the injection pump in 2 minutes. The, A.C. lift pump has a ridiculously small knob on the priming lever, which makes hand pumping a painful business.

The engine cowl was then replaced and the passenger seat returned to its proper position in 18 seconds. As a final task I changed a 'fuse in 10 seconds. The fusebox is tucked away under the right side of the windscreen, above the pedals.

The Trader is .certainly one of the easiest forward-control vehicles of this size on which I have ever

had to work. Its handling characteristics call for little comment other than to say that they are firstclass.

All the controls are well placed and light in operation. The steering has the right amount of castor 'effect without making it heavy, and the gearbox synchromesh works extremely . well, the direct lever allowing fast and positive changes.

The engine is quiet and smoothrunning, and the double-skinned cowl, interlined with glass-fibre, successfully cuts out most of the other engine noise. At 30-40 m.p.h. the engine note is unobtrusive.

Stowage space in the cab is restricted, being confined to a small log-book pocket between the seats: A good interior light throws a concentrated beam on to the rear of the engine when the cowl is removed, in addition to illuminating the cab generally. Only one driving mirror is supplied, but twin vacuum-operated windscreen wipers are standard and these sweep over 60 per cent. of the screen.

The driver's seat is adjustable fore and aft over a limited range. Nevertheless, my companion during the test, Mr. Jess Wainwright, of the Ford experimental department, who is 6 ft. 24in. tall, did not seem to be cramped when driving. 11 would, however, still like the pedals to be placed a little farther from the driver's seat.

The Thames Trader 12-ft. 8-in.wheelbase 5-tonner, with six-cylindered oil engine, has a basic chassis price of £975. The cab adds £70 to this figure, whilst the 15-ft. 6-in, drop-sided body costs £105. Purchase tax of £216 is. 6d. is payable in Great Britain.

A single heater unit, as fitted to the test vehicle, costs £10 10s., dual passenger seat, £4 10s., flashing direction indicators, £6 10s., and the set of rear dampers, £.7 10s. (including purchase tax).